Why are centerline rumble strips utilized?

Centerline rumble strips are applied on the longitudinal joint of the pavement. Centerline rumble strips can reduce the occurrence of head-on collisions by up to 50%1 . Because the centerline is the road’s most permeable section, it is very susceptible to natural elements such as water and air.

Why is VRAM important to use when centerline rumble strips will be installed?

By applying VRAM at the time of construction under the surface where the centerline rumble strips will be installed, permeability is reduced in this most critical area of the road. VRAM is a Void Reducing Asphalt Membrane. VRAM is an investment to protect the roads, while rumble strips are an investment to protect drivers. It is important to know when VRAM is used on these projects, centerline rumble strips can be installed without compromising road life.

About this project:

On April 19th of this year, a mill and fill project took place on SR-111 from Floyd County Line south to SR-211. This is a two-lane highway with a center line rumble strip to be installed on the entire project. Also for this project, the addition of shoulder rumble strips will be installed on a portion of the project north of Caesars Casino to Floyd County Line.

VRAM was applied on the centerline of State Road-111, starting at State Road-211. The width of application for VRAM on this project was targeted at 24” wide and was to be applied over 10,907 feet. Once the VRAM was applied, the paving of the road took place.

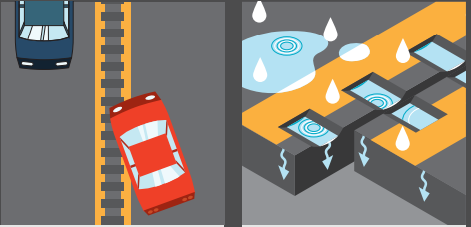

Rumble strips can cause water to pool in vulnerable areas

Centerline rumble strips are applied across the center of the pavement. Over time, as water collects in these rumble strips, the pavement will eventually degrade, break up and pothole.

Here is a video that further explains what a Void Reducing Asphalt Membrane (VRAM) is, and the benefits of utilizing it. https://www.youtube.com/watch?v=GmqN7RYpACE

When VRAM is utilized with rumble strips, a better outcome can be achieved. VRAM is applied at the time of construction to reduce permeability under the surface of the pavement where centerline rumble strips will be installed. VRAM works from the bottom-up. After the hot mix asphalt is placed and the heat causes the material to migrate upwards air voids are filled. As a result, the filling of voids around the rumble strips will reduce permeability and extend the life of the pavement.

Protect Drivers. Protect Workers. Protect Your Roads.

When both VRAM and rumble strips work together, there is protection for roads, drivers, and workers. VRAM helps create roads that are longer-lasting, which equates to infrastructure money going further. Because less road maintenance is required VRAM is also an investment in safety.

Other Projects and Studies Supporting the Use of VRAM and J-Band®

You can review other projects by reading other stories here within the news tab, and by utilizing our Project Map and Sorter tool on this area of our website: https://thejointsolution.com/project-map/

You can view Studies that other states have conducted that recommend VRAM as a solution to building longer-lasting, safer roads by clicking here: https://thejointsolution.com/resource/studies/

J-Band® is a VRAM product from Asphalt Materials, Inc. and was created in the labs of the Heritage Research Group. VRAM has been helping roads last longer since 2002 and has been used in 22 States and The District of Columbia.

Editor’s Notes:

VRAM, Void Reducing Asphalt Membrane, is referred to in Illinois as LJS, Longitudinal Joint Sealant.

1 U.S. Department of Transportation Federal Highway Administration, FHWA Home / Safety / Roadway Departure / Center Line Rumble Strips (T 5040.40)