Why VRAM is Like an Insurance Policy for Agencies?

When identifying the weakest points in a pavement, longitudinal joints tend to stand out. This is due to the voids and connected voids, which cause the joints to be vulnerable to the elements, such as air and water. When the elements enter the longitudinal joints’ voids, it can cause the joint to deteriorate, crack, and create potholes.

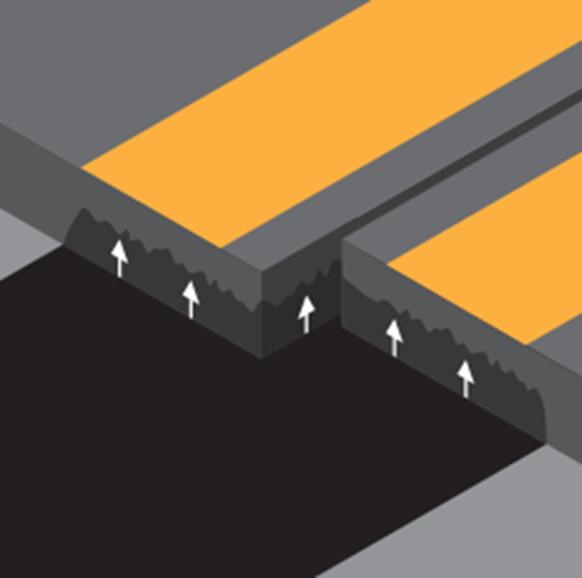

By applying a Void Reducing Asphalt Membrane (VRAM) at the time of construction, pavement voids are filled from the bottom up. When the asphalt mix is placed on top of the VRAM, it migrates upwards into the asphalt mix from the bottom up.

This makes the joint less vulnerable to elements and creates stronger, safer, and more sustainable roads. One of the primary reasons for the benefits of VRAM is the reduced need for ongoing road maintenance and repairs.

The benefits of using VRAM are proven over an extended period of time. Therefore, it is important that we monitor the impact of using VRAM across a number of different projects. We often work with local and state Departments of Transportation (DOT) to ensure that each project receives an annual review. Recently, we reviewed a project on I-81 in Schuylkill County, Pennsylvania.

2023 Project Review

- Owner: Schuylkill County

- Applicator: Illiana

- Prime Paving Contractor: New Enterprise Stone and Lime Inc.

- Location: I-81 (MP 131.7-MP 133.85)

- State: Pennsylvania

- County: Schuylkill

- Date Constructed: 10-17-2018

- Date Reviewed: 4-5-2023

- Weather Conditions on the Day of Review: 40°F, sunny at 10:00 a.m.

Project Observations

In order to view the performance of the VRAM application, we had David Powers (Associate Asphalt), Daniel Clark (PennDOT Central Office), Garth Bridenbaugh (District 9), and Brent Hentz (Distric5) review the I-81 project in Schuylkill County.

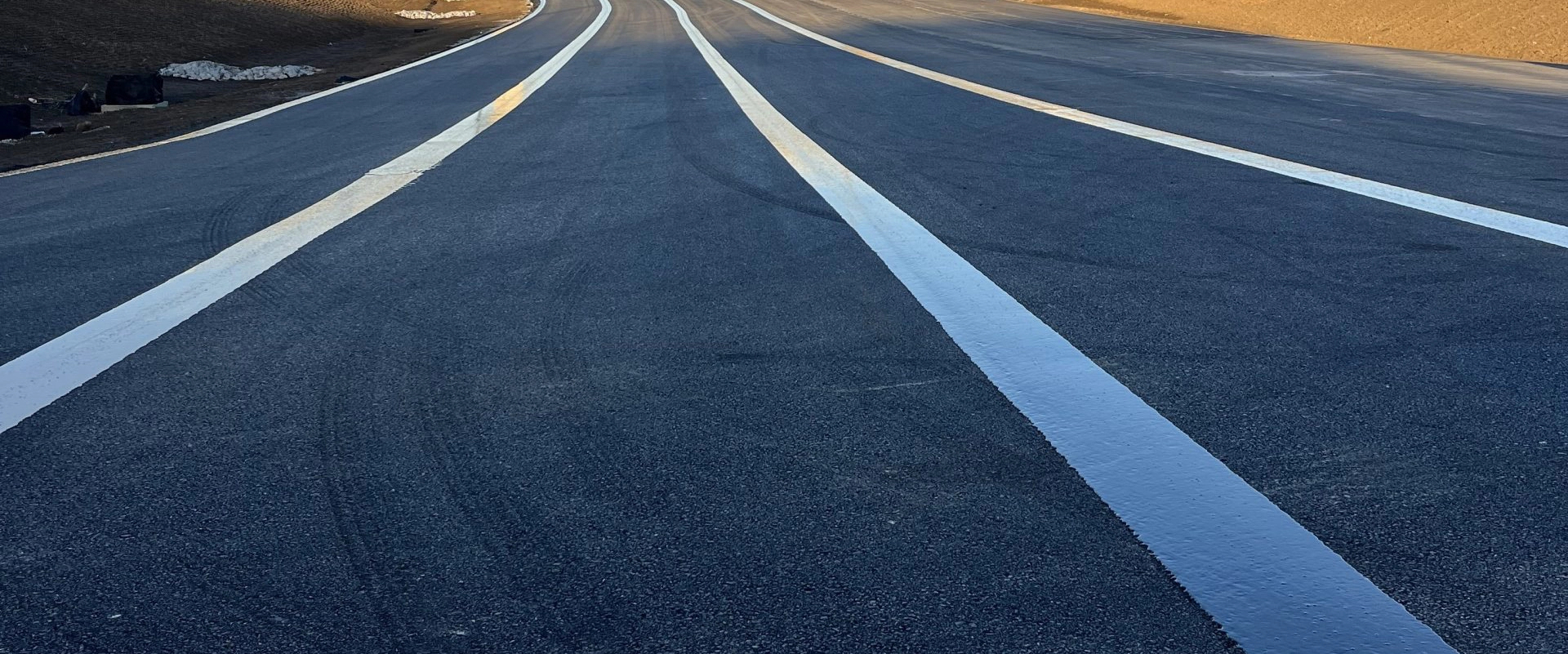

Below are observations and images from this year’s review.

vs. Non-VRAM on right

TEST SECTION - VRAM

Although the test section of this project did have a slight joint opening in a few areas, the separation did not go into the paving mat. This is something that can happen with a project five years after construction. The majority of the VRAM Test section was joint opening free. VRAM continues to protect the longitudinal joint from air and water.

CONTROL SECTION - NO VRAM

The No VRAM Control Section has substantial cracking and joint opening.

VRAM Outperforms Control Section

Overall, the VRAM Test Section has outperformed the Control Section. By using VRAM, District 5 is able to save infrastructure funds by avoiding the financial burden of having to re-invest dollars in repairs and maintenance at the longitudinal joint.

Within 5 years, District 5 plans to invest more infrastructure funds into VRAM as a proactive construction process to prevent premature failure of longitudinal joints.

When roads last longer, infrastructure funds go further. Since roads last 3-5 years longer with VRAM, agencies that invest in VRAM typically see a return on investment (ROI) of 3-5x. For example, an agency investing $100K in VRAM will typically experience a $300-$500K savings from avoided and deferred maintenance and repair costs.

Interested agencies can use our interactive calculator to learn more about how longer-lasting roads save time, money, and lives by clicking here.

The VRAM Story

At Asphalt Materials, we understand that longitudinal joint deterioration has long been a problem for engineers, applicators, and the communities we live in. VRAM was developed to help create longer-lasting, safer roads through a collaboration between state transportation agencies, industry experts, and the laboratories at Heritage Research Group.

Unlike other treatments, VRAM is a materials approach that significantly reduces air voids in longitudinal joints. J-Band® is Asphalt Materials’ VRAM product. J-Band as a materials approach, is applied prior to paving under the eventual location of the longitudinal joint. As the hot mix asphalt (HMA) is installed on top of J-Band, it migrates upward, fills voids, and reduces permeability. Since 2002, this approach has improved the performance of centerline joints and entire pavements in more than 23 states and the District of Columbia (DC).

J-Band® is a product of Asphalt Materials, Inc. and was created in the labs of Heritage Research Group. To learn more about J-Band, or to connect with our team, you can email us at: Marketing@Asphalt-Materials.com.

Editor’s Notes:

J-Band®, CCAP® and T-Bond® are registered trademarks of Asphalt Materials, Inc. AMIBIND™, AMIBOND™, AMICYCLE™, AMIGUARD™ and AMISEAL™ are trademarks of Asphalt Materials, Inc.

J-Band® was created in the labs of the Heritage Research Group (HRG) and is a product of Asphalt Materials, Inc. (AMI). To learn more about J-Band, visit www.thejointsolution.com.