Pavement sustainability continues to be one of the most crucial areas of research in the asphalt industry. While it is common to understand sustainability in a purely environmental context, truly sustainable products and innovations also have positive economic and social implications.

Below, industry sustainability thought leader and Sustainability Engineer at the Asphalt Institute, Dr. Chait Bhat, examines the appropriate scope for comparing Environmental Product Declarations (EPDs) per the International Organization for Standardization (ISO) standards language in Asphalt Magazine. His article follows a previous article from Dr. Mark Buncher covering the appropriateness of comparing material EPDs.

In the article Dr. Bhat explores two questions:

- What would be the appropriate scope to compare EPDs?

- Who should oversee the development of an EPD and its Product Category Rules (PCR) beyond cradle to gate?

An excerpt is included below:

The tale of complexity

How many times have you heard someone say: “But it’s too complex” after you propose a new idea? Complexity should not be the reason we do not pursue a methodology that provides a more complete approach to pavement sustainability.

While the logic for advocating, developing, and using just cradle-to-gate EPDs as part of green public procurement may be that of faster implementation, it is important to remember the overall big-picture objective. Comparing EPDs of materials that may have different long-term performance periods can lead to unintended consequences and be detrimental to the big picture of true sustainability.

“Complexity” being used as a reason for not implementing a more holistic methodology is not new to the asphalt pavement industry. The same “it’s too complex” logic led to a less-than-complete approach to address cracking in the development of Superpave specifications over 30 years ago. Many have said Superpave fixed the rutting problem but at the expense of cracking. We now are seeing many cracking tests being developed and evaluated as part of the more holistic Balanced Mix Design (BMD) method for designing asphalt mixtures.

The challenge

As an industry, we need to challenge ourselves to think beyond the scope of material cradle-to-gate EPDs by exploring a more holistic approach to sustainability that uses pavement-level PCRs and EPDs. This is especially true when using EPDs as part of green public procurement and policy. Not doing so may be easier but will not achieve true sustainability.

To read the full Asphalt Magazine article click here.

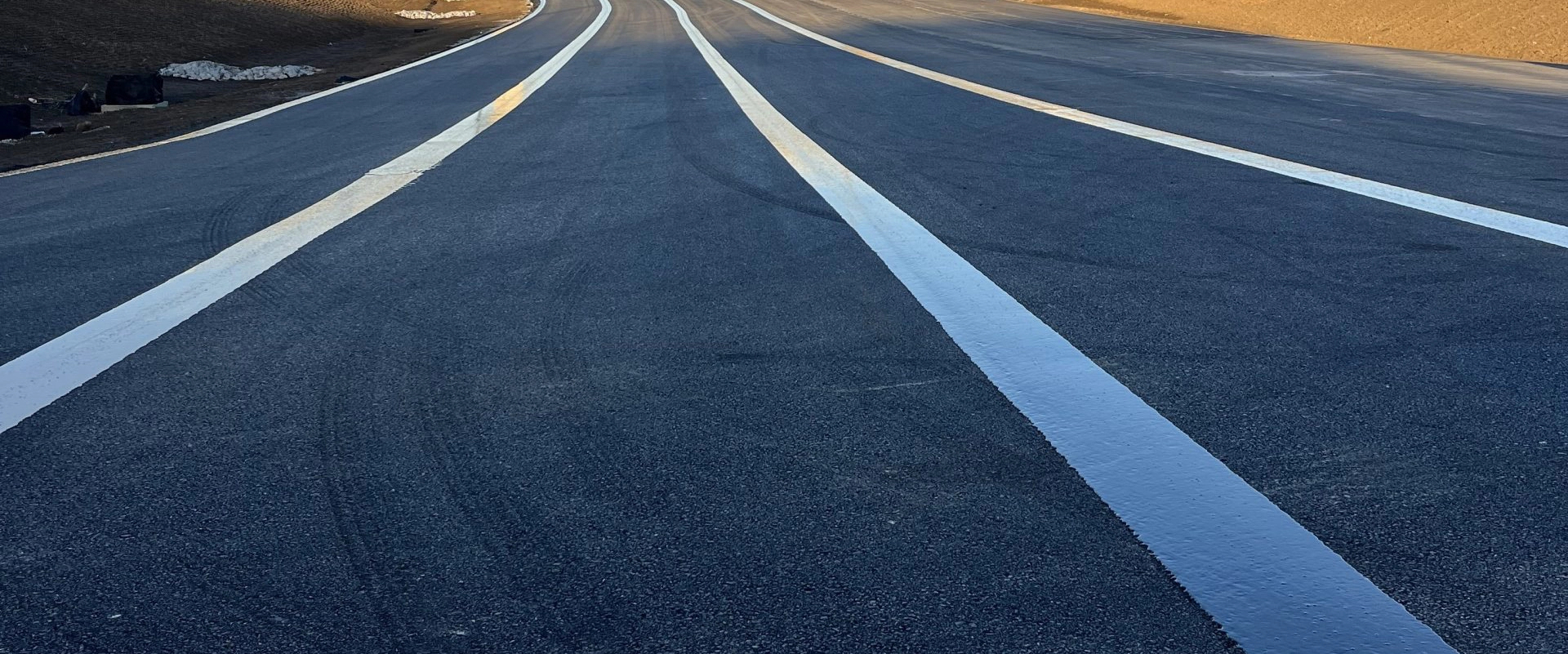

VRAM is a Sustainable Solution to Longitudinal Joint Deterioration

Void reducing asphalt membrane (VRAM) is a complete approach to pavement sustainability. At Asphalt Materials, we understand that longitudinal joint deterioration has long been a problem for engineers, applicators and the communities we live in. VRAM was developed in collaboration between state transportation agencies, industry experts, and the laboratories at Heritage Research Group to help create longer-lasting, safer roads.

Not only does VRAM help build longer-lasting roads that are more environmentally friendly, but when roads last longer, infrastructure dollars go further.

You can explore our interactive map to see more projects that have utilized VRAM at the time of construction and learn more about how longer-lasting roads save money, time and lives here.