Written by Naarah Holloway

Did you know that the first part of the pavement to fail is the longitudinal joint? This is due to the joint being vulnerable to elements such as water and air. The elements work their way through the joint through a gap which causes the joint to deteriorate, crack, and pothole. This is what causes the longitudinal joint failure; therefore, the rest of the road will fail shortly thereafter which causes the need for more maintenance.

When roads are reinforced with a Void Reducing Asphalt Membrane (VRAM), they are better economically, socially, and environmentally sustainable compared to roads without VRAM.

How Does It Work?

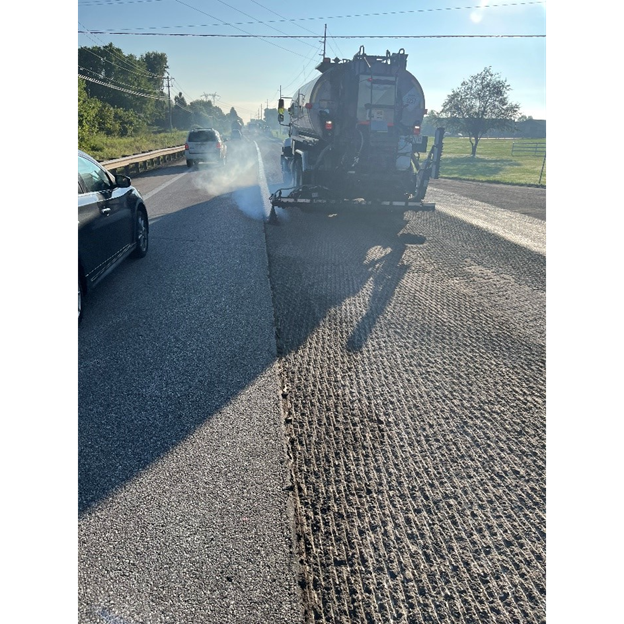

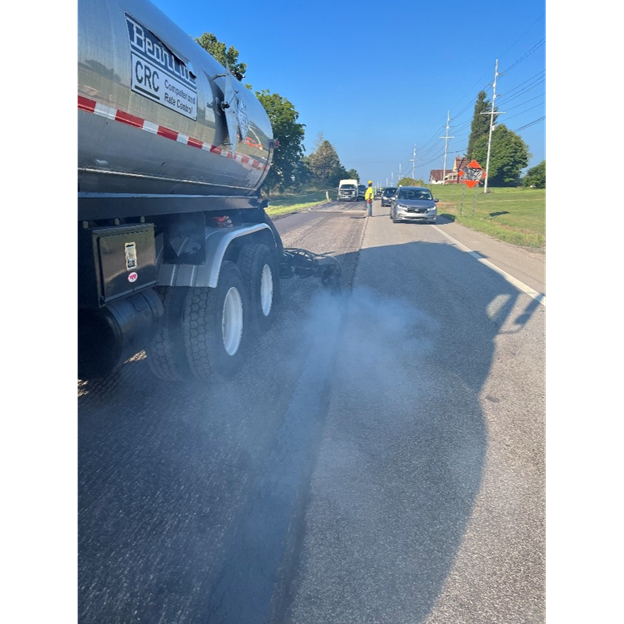

VRAM is applied prior to paving under the eventual location of the longitudinal joints and makes roads less vulnerable to the damaging effects of the elements. VRAM is a blend of asphalt binders, polymer, and asphalt modifiers. The VRAM holds the new asphalt in place and migrates upward into the asphalt layer, filling the air voids.

Our Specialty Products team collaborates with local and state Department of Transportations (DOTs) to monitor the performance of VRAM on specific projects across 25 states. For the last 20 years, observations have shown that pavements using VRAM last 3-5 years longer compared to those not using VRAM.

ODOT SR-62, Licking County VRAM Application

Project Details

- Owner: Ohio Department of Transportation (ODOT)

- Applicator: SCI

- Prime Paving Contractor: Shelly Co

- Location: SR-62

- State: Ohio

- County: Licking

- Date Constructed: August 17th, 2023

VRAM Observation

About 10.5 miles of SR-62 was paved from the Licking County line to Shipley Road through Johnstown. The personnel present on the project were SCI’s Howard and Troy, AMI’s Field Support Engineer Chad Crosby, and Paving Foreman Joe Bice.

The VRAM application started at 8:10 a.m. and the ambient temperature at the start was 61°F. The VRAM cooled within three minutes and Shelly Co did a fantastic job of cleaning the milled surface. The project is an ODOT test versus control for the rumble strips centerline.

Paving Observation

Paving followed shortly after the application of VRAM. Paving began at 11:00 a.m. and had an ambient temperature of 71°F. The mix temperature behind the screed averaged 312°F with ¾" migration prior to rolling. The equipment used was a Vogele 2003 3i paver, a Hamm HD120i steel drum roller and a HAMM HD110i steel drum roller.

Conclusion

Overall, the application of J-Band®, Asphalt Material’s VRAM product, was applied successfully. J-Band® has played a vital role in reducing air voids and connecting voids within longitudinal joints across 25 states, including the District of Columbia (DC), since 2002.

For a closer look at projects that have incorporated VRAM during construction and to discover the benefits of longer-lasting roads in terms of cost savings, time efficiency, and safety, you can explore our interactive map here.

Editor’s Notes:

J-Band®, CCAP® and T-Bond® are registered trademarks of Asphalt Materials, Inc. AMIBIND™, AMIBOND™, AMICYCLE™, AMIGUARD™ and AMISEAL™ are trademarks of Asphalt Materials, Inc.

J-Band® was created in the labs of the Heritage Research Group (HRG) and is a product of Asphalt Materials, Inc. (AMI). To learn more about J-Band, visit www.thejointsolution.com