For decades, road managers have been plagued by a problem with no effective solution. As sure as death and taxes, longitudinal joints have been the first part of a pavement to fail. This failure inevitably leads to unplanned road maintenance and eventual pre-mature reconstruction.

In 2002, some of the leading minds in the pavement industry got together to end this problem for good. They created a unique product, the void reducing asphalt membrane (VRAM), which protects longitudinal joints from the destructive effects of air and water, definitively increasing the life of longitudinal joints three-fold.

Today, VRAM has proven itself in 27 states and counting. This project, commissioned by ODOT, demonstrates the power of VRAM as a preservation tool.

Project Details

- Owner: Ohio Department of Transportation (ODOT)

- Prime Paving Contractor: Gerken Materials. Inc.

- VRAM Applicator: Specialized Construction Inc. (SCI)

- Location: US-6, McClure, OH, Henry County

- Control Section: MP 17.81 to 22.93

- Test Section with VRAM: MP 22.93 to 27.82

- Date Constructed: September 28, 2017

- Date Reviewed: 7 Years Later, September 26, 2024

Project Observations

When this road was re-paved in 2017, a 12.5mm Type A (446) was installed in a 1 ½” thick mat. This project included a roughly four-mile test section where J-Band®, the premier VRAM, was applied in a 15” band at the location of the future HMA longitudinal centerline joint. For approximately five miles, no VRAM was applied for the control section.

Chad Crosby, Field Support Manager, returned to review the project on a cloudy 70°F day almost exactly 7 years after initial construction.

Control Section Review

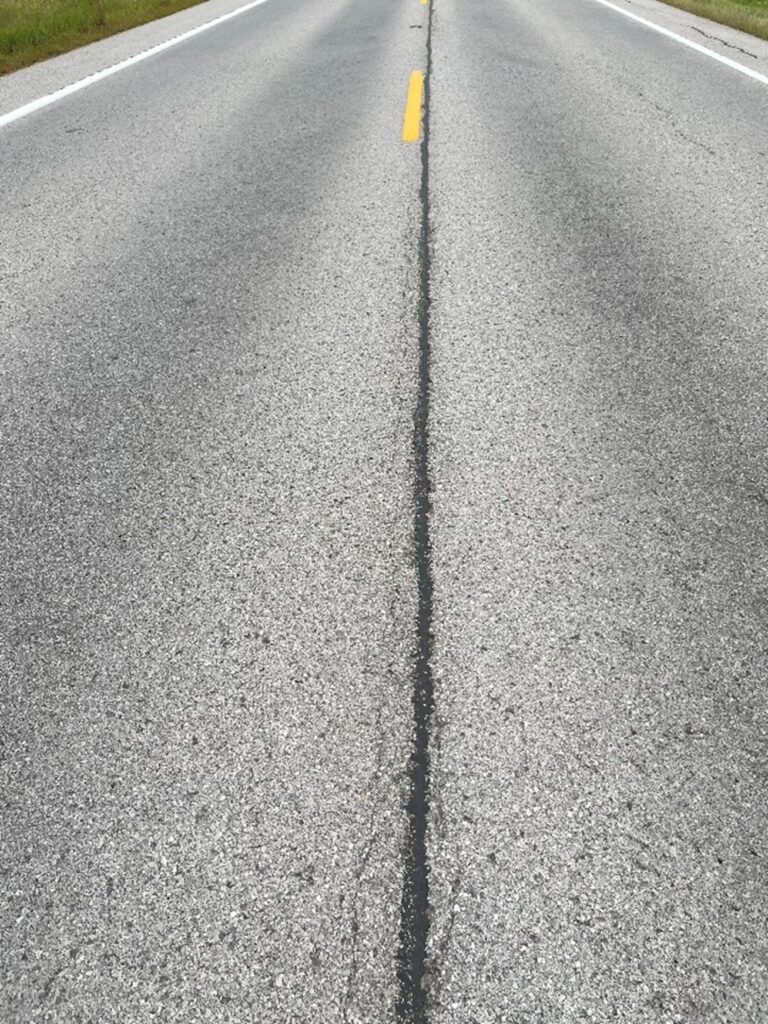

This test project on US Route 6 is notable given the contrast between the control and test sections. The longitudinal joint in the control section has experienced considerable cracking, despite being crack sealed within the first few years of its life. The section has 100% cracking with ½” to 1” cracks throughout. Parallel cracks have also begun to develop next to the centerline.

Control Section Images (Without VRAM)

VRAM Test Section Review

In dramatic contrast, the test section with VRAM shows typical 1/8” openings in just 20% of its duration. There are a few occurrences of crack-sealing about 1’ from the centerline.

VRAM Test Section Images

The proof is in the pavement. On this US state highway, J-Band has kept the centerline intact by reducing air voids and permeability. Lab testing of cores taken from VRAM-treated-centerlines shows that the use of a VRAM decreases pavement permeability. From both lab and field tests, VRAM has proven its ability to make the bottom layer of pavement impermeable.

To learn more about how you can add J-Band to your projects, get in touch with our team today! We’d love to discuss the possibilities.

Editor’s Notes:

J-Band® is a registered trademark of Asphalt Materials, Inc. (AMI). J-Band® was created in the labs of the Heritage Research Group (HRG) and is a product of AMI.