We all know how important and difficult it is to consistently achieve adequate density at longitudinal construction joints. These joints are typically the first place a pavement begins to crack or pothole, largely due to higher air voids compared to the rest of the mat. Forward-thinking agencies are increasingly turning toward a Void Reducing Asphalt Membrane (VRAM) to solve the joint durability problem, but does VRAM offer the same benefits when paired with a notched-wedge joint?

This combination, as used in the project featured below, significantly improves joint performance and longevity.

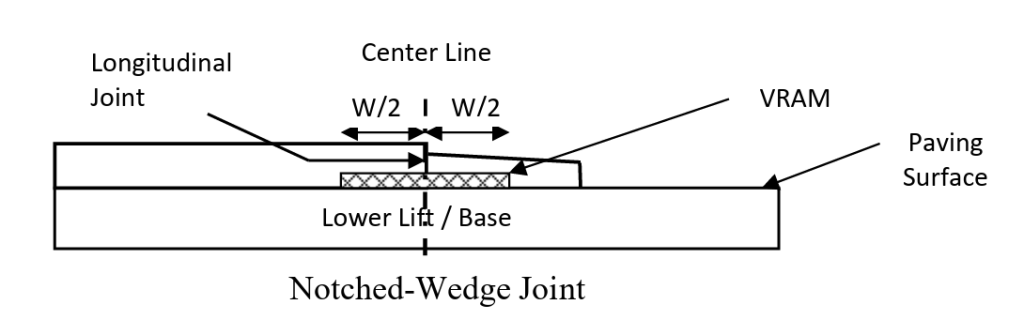

The Notched-Wedge Joint

Over the last two decades, the use of a notched-wedge geometry on the unconfined paving joint has become a common approach for agencies to address the safety concerns of live traffic crossing the paving joint. In fact, this type of joint geometry was originally created for safety reasons. Usually, states will specify that if the thickness of the overlay is greater than 1.5 inches and the road stays open to traffic, it needs a notched-wedge joint. Today, many states, including Iowa, Montana, Connecticut, Texas, Wisconsin, and Michigan (where it’s known as a “Michigan joint”), regularly use variations of this technique.

The first lane of a notched-wedge pavement lane, from Iowa and Wisconsin

The notched-wedge method uses a mechanical attachment to create a joint with better structural integrity. The paver forms a vertical notch, followed by a tapered wedge that slopes from the top of the mat down to the unpaved lane. This is typically accomplished using a bolted-on device at the screed’s edge on the unconfined side of the paver. When the adjacent lane is paved, the fresh asphalt overlaps the wedge.

This construction method does present a few challenges:

- Compaction of the wedge is often not measured.

- Notched-wedge geometry can create areas of bridging or segregation depending on mix design.

- There have been reports of "reflective" cracking caused by the termination of the wedge or second notch, resulting in the appearance of two joints.

VRAM: A Material Solution to a Structural Problem

While notched-wedge joints offer safety benefits to the public during construction, VRAM can help to ensure lasting durability of the finished joint by addressing the root cause of joint failure—permeability created by high air voids.

J-Band®, the premier VRAM product, has been used in over 27 states to reinforce longitudinal joints and rumble strips. Applied as a hot, polymer-modified asphalt membrane beneath the joint, it migrates upward into the asphalt during paving, filling voids and sealing the joint from the bottom up. This prevents water infiltration, one of the main culprits behind early deterioration.

And the economics are compelling: agencies save at least $2 in deferred maintenance for every $1 invested in VRAM.

Case Study: Poweshiek County, Iowa

A recent resurfacing project on 480th Avenue in Poweshiek County offers a real-world example of how VRAM and notched-wedge paving work in tandem.

Project Details

- Owner: Poweshiek County, Iowa

- Prime Paving Contractor: Manatts

- VRAM Applicator: Evergreen Roadworks

- Location: 2.52 miles of 480th Ave, Montezuma, IA

- Date: May 29-30, 2025

Step 1: VRAM Application

Evergreen Roadworks applied an 18-inch-wide band of J-Band VRAM along the centerline joint on the binder course, before the final surface layer was placed. In just over an hour, the crew covered all 13,385 linear feet of the joint.

Evergreen Roadworks 18” VRAM band application

Step 2: Notch Wedge Paving Process

The next day, Manatts returned to pave the surface course. After applying a tack coat — covering both the binder and the VRAM band — the crew laid 1.5 inches of asphalt using a paver equipped with a notched-wedge attachment.

As the hot mix was compacted, the VRAM migrated upward into the asphalt layer, reducing air voids from the bottom up and creating a dense, sealed joint resistant to water damage. For a detailed breakdown of how to pave a notch wedge joint, explore this AsphaltPro article.

Diagram for VRAM application from the VRAM specification

As the Asphalt Materials Inc. specification guidelines states: “Notched wedge and tapered joint geometries can vary; the VRAM width (W) is split in two at the notch or beginning of the taper. VRAM material wider than the wedge or taper is possible and acceptable.”

Tack coat over the VRAM band / Notched-wedge paving

VRAM Improves Performance

By adding VRAM below the joint, air voids near the joint are filled with polymer modified asphalt binder, and permeability is significantly reduced. The asphalt rich area is resistant to crack propagation, slowing the rate of deterioration at the joint, and reducing maintenance requirements. See a full research summary here.

Long-Term Value

This project is just one of many across the country demonstrating the success of using VRAM when a notched-wedge joint is required. When agencies pair smart paving techniques with proven material innovations, they’re not just building roads; they are investing in longer-lasting infrastructure. In fact, joint areas treated with VRAM often last as long as the rest of the pavement, something traditional joints rarely achieve.

Additional projects include: Hendricks County, Indiana: CR 500E, Sept. 2018 (pictured), IDOT IL 106 in Greene County, September 2016

Ready to Reinforce Your Joints?

Want to see how VRAM could extend the life of your pavement? Our team is ready to help you evaluate your options and identify the right solution for your next project. Reach out today!

Editor’s Note

J-Band® is the premier VRAM and a registered trademark of Asphalt Materials, Inc. (AMI). J-Band was created in the labs of the Heritage Research Group (HRG) and is a product of AMI.