As pavement technologies evolve, so do the best practices for road performance evaluation and maintenance. One such innovation, J-Band® void-reducing asphalt membrane (VRAM), protects vulnerable longitudinal joints from the damaging effects of air voids and water intrusion. This leading-edge material is being used by state and local agencies to extend road life and decrease maintenance costs.

With VRAM in the toolkit, road managers can take a proactive, rather than reactive, approach to joint maintenance. The protection from this unique solution reduces the need for early and costly maintenance practices.

Typical Joint Performance Expectations

Seasonal temperature and moisture changes have a profound impact on asphalt pavement joints. Even well-constructed joints will face strain under traffic and environmental exposure.

Asphalt’s natural flexibility allows it to accommodate these shifts without needing expansion joints as required for concrete pavements. When a pavement mat does experience fluctuations, the joints are the first place it can be visually seen. Movement at the longitudinal joint is typically 1/16” to 1/8” (3 mm) per year and 1/2” to 3/4” in about five to seven years. This range is considered normal for well-constructed joints.

However, environmental conditions such as repeated freeze-thaw cycles and moisture infiltration can amplify joint movement and lead to extensive cracking or vertical offsets, especially if the joint was poorly compacted or lacks proper sealing.

For typical joints (without VRAM), crack sealing is critical as soon as these openings appear; with joints that have VRAM, road managers can rest easy knowing these joints are still protected below the surface.

Why Joint Openings Occur, Even With VRAM

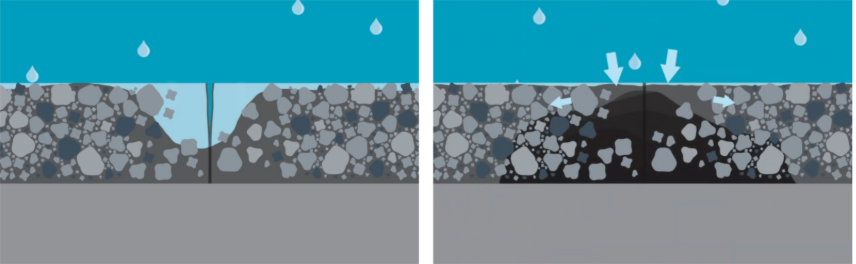

Applied at time of construction, VRAM is typically placed as an 18” wide band under the joint before surface course paving. The asphalt mixture is applied on top of the VRAM, which activates the material. As the rolling operation works across the mat, the highly polymer-modified asphalt migrates up to 75% of the way up into the surface course, filling the interconnected air voids to create a dense and durable joint area.

J-Band does not migrate all the way to the surface. This means that after a mix has been in place for a few years, it’s not uncommon to observe the joint beginning to open. While this might initially raise concerns, it’s important to understand that this is normal and expected behavior—not necessarily a sign of distress.

Once paved over, VRAM melts and migrates 50-75% of the way up into the HMA mat.

Without VRAM, in a permeable mix, water damages the pavement over time. With VRAM, air voids are filled in the lower portion of the mix, protecting the pavement.

Is Crack Sealing Necessary Above J-Band?

In many cases, sealing the joint opening may not be required. The VRAM layer beneath the joint is rich in asphalt, which provides a strong barrier against water penetration. This asphalt-rich bottom resists damage and helps maintain the integrity of the pavement, even if the surface joint appears open.

Often, when a crack is observed along the surface of the VRAM-protected longitudinal joint, depth is minimal, typically 1/8-inch to ¼-inch. While it doesn’t hurt to seal these joints early, it isn’t necessarily required for their long term performance.

Joint Performance With and Without VRAM

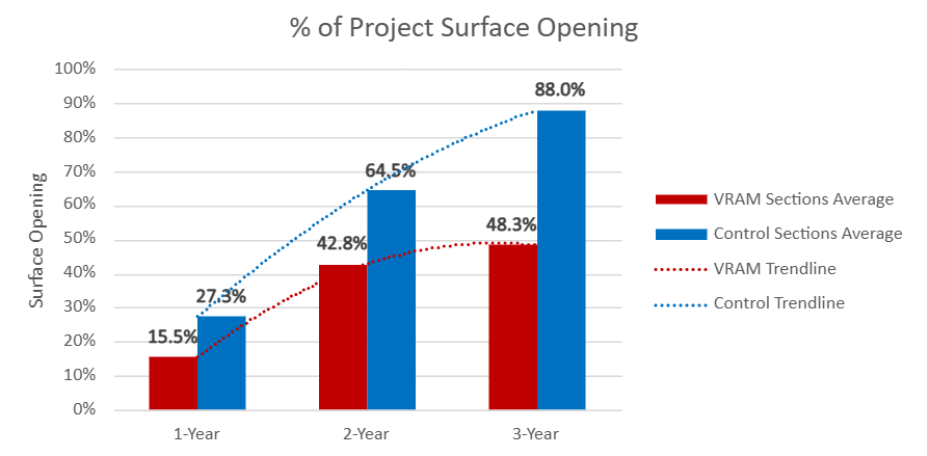

To better understand the prevalence of early life surface openings when VRAM is used, the team examined 20 VRAM projects across the Midwest, which included control sections. For three years, the team documented the percentage of each project’s centerline joint that presented a surface opening for both the VRAM joint section and the control joint section. The following figure displays the average joint performance.

These numbers show that longitudinal joints with VRAM have fewer joint surface openings. But VRAM does more than minimize surface openings. It effectively reinforces the entire longitudinal joint area above it by filling air voids at the edge of a lane where compaction is challenging.

This insight is supported by decades of performance data, starting as early as 2002. The visual below compares two of the older VRAM projects in Illinois. The control sections (pictured on top) show significant cracking and deterioration long before the rest of the mat. In contrast, the test sections with VRAM showed the expected joint openings but also maintained integrity for the full life of the pavement.

Current Practices and Misconceptions

Despite the protective nature of VRAM, many maintenance crews continue to seal joint openings as part of routine crack sealing operations. This is often due to a lack of awareness that VRAM is present under the joint, or uncertainty about its long-term performance. As a result, agencies may be spending time and resources sealing joints that are already well-protected.

Both IDOT and INDOT have adopted VRAM for use on all their major surface course resurfacing projects. In fact, all across the country, agencies are choosing VRAM for its proven ability to save time and money on future longitudinal joint maintenance.

Key Takeaways for Agencies

- Small joint openings in J-Band mixes are expected and not necessarily problematic.

- VRAM provides effective water resistance, reducing the need for early crack sealing.

- Performance data from multiple states shows VRAM-treated sections consistently outperform control sections.

- Education and awareness among maintenance crews are essential to optimize sealing practices.

Have more questions? Our team is here to talk.