A Void Reducing Asphalt Membrane, (VRAM), project took place in Marshall County, Indiana on the beautiful afternoon on June 24, 2022. The work was done over 15 miles on US-30 from State Road 17 to State Road 19.

Project Details

On this day, VRAM was applied on the centerline joint and travel lane shoulder joint, both targeted at a bandwidth of 18” wide. The VRAM applicator for this project was Road Fabrics Inc. (RFI), and the prime paving contractor was Rieth Riley.

This project continued in the early days of July, when the paving of the asphalt took place. The project was successful and came to a close!

Benefits of VRAM

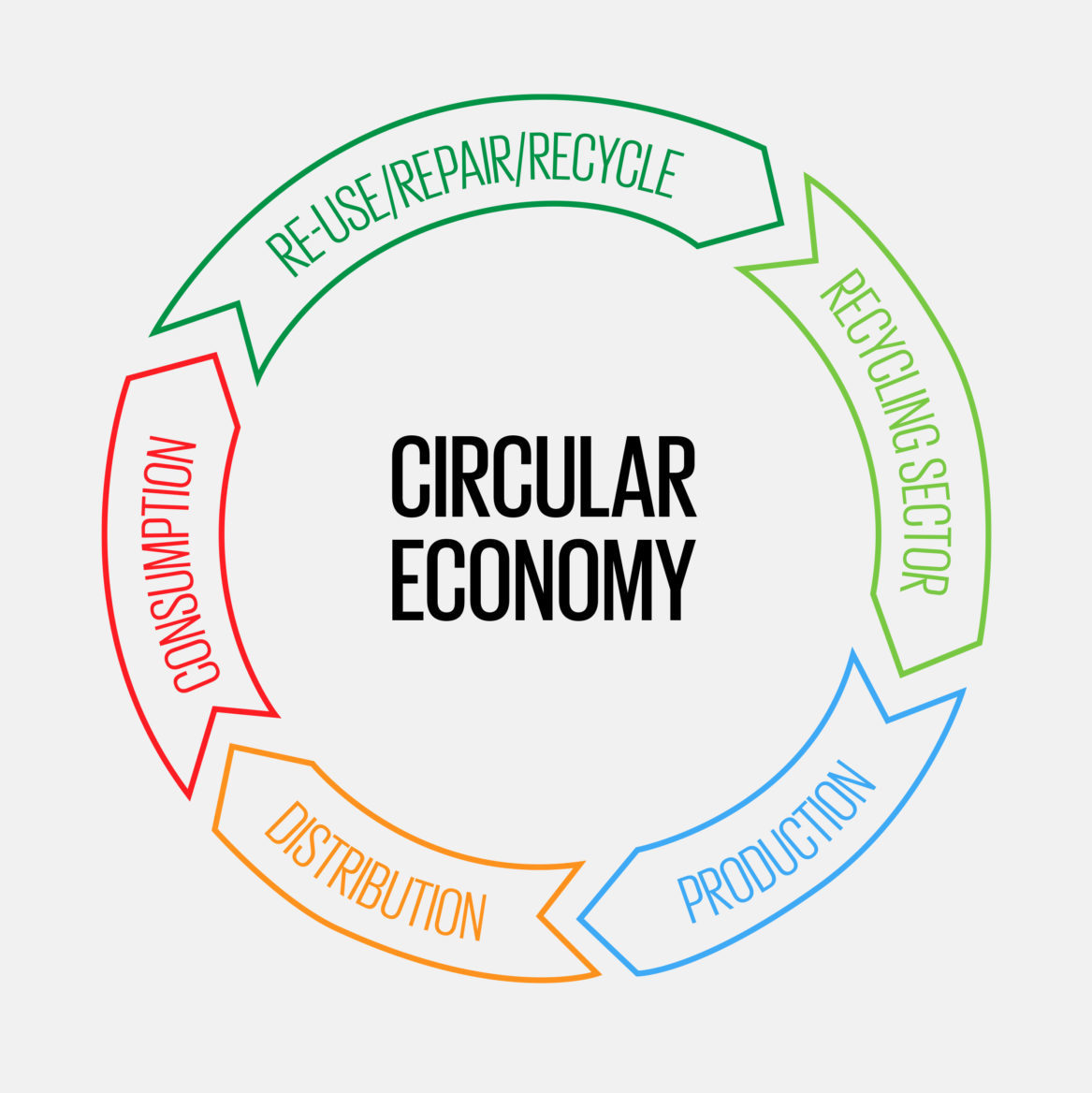

With the utilization of VRAM, Marshall County is helping to create a more resilient and reliable infrastructure and supply chain. Not only is it helping to create a more resilient and reliable infrastructure and supply chain, but also preserving the lifespan of the roads. By building roads that last longer with the utilization of VRAM, multiple benefits follow. One main benefit includes being environmentally friendly. Since asphalt is the most recycled material over paper and cans, it is an important contributor to a circular economy. A circular economy is when products are used, recycled, and then reused repeatedly.

The Power of VRAM

As road managers know, the first part of the pavement to fail is the longitudinal joint located at the centerline of the road. This joint is extremely susceptible to the elements, such as air and water. These natural elements will work down through the gaps in the road, which results in pre-mature deterioration, cracking, and potholing of the joint. And once the longitudinal joint fails, the rest of the road soon follows, which eventually triggers the need for maintenance of the entire road.

However, by including the addition of VRAM, it ensures the protection of the road from deterioration, saves tax dollars, and even saves the environment. With the presence of longer lasting roads, it ultimately reduces the need for constant repairs and touch-ups, which in the end saves the natural resources and reduces the emissions that arise from the construction equipment.

J-Band® is a VRAM product from Asphalt Materials, Inc. and was created in the labs of the Heritage Research Group. VRAM has been helping roads last longer since 2002 and has been used in 22 States and The District of Columbia.

J-Band is an investment for asphalt roads, and helps infrastructure dollars go further, since the roads can last up to five years longer than roads without VRAM. It delivers a return on investment of 3 to 5 times its initial cost.

Editor’s Notes: VRAM, Void Reducing Asphalt Membrane, is referred to in Illinois as LJS, Longitudinal Joint Sealant.