Rumble Strips are an Important Safety Measure

The Transportation Research Board (TRB) Annual Meeting was held in Washington, D.C. in early January. This year’s theme was Rejuvenation Out of Disruption: Envisioning a Transportation System for a Dynamic Future. The meeting included exhibitors from academia, industry, and government agencies presenting the latest research findings, technical developments, and implementation efforts within the asphalt industry.

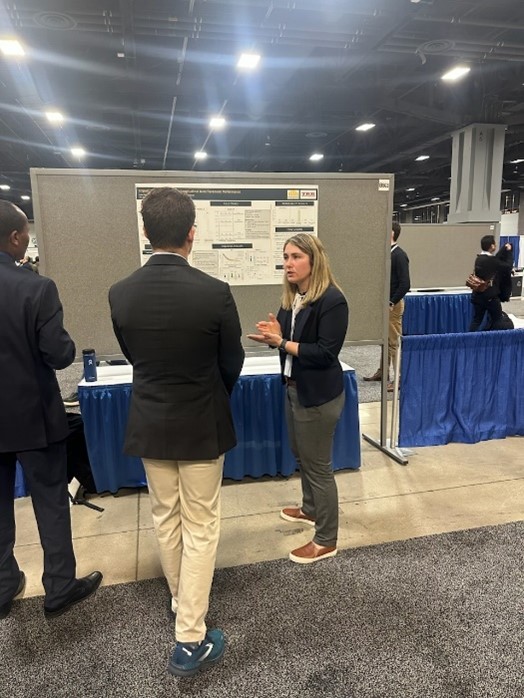

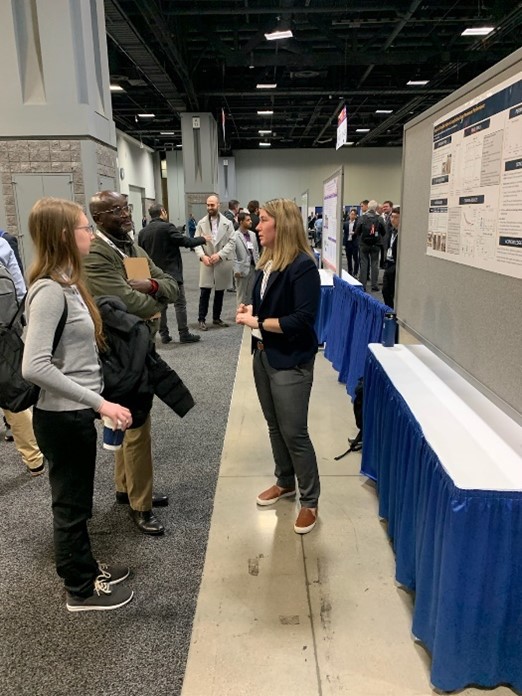

Asphalt Materials and HRG Labs had the unique opportunity to present two different posters at this year’s Transportation Research Board (TRB) Annual Meeting in early January. HRG participation included a poster presentation by Katie DeCarlo of a paper titled “Impact of Rumble Strips on Longitudinal Joint Pavement Performance,” which was co-authored by Todd Thomas of Asphalt Materials and Jason Wielinski of the Asphalt Institute.

Rumble Strips Can Help Save Lives

With more than 42,900 fatalities occurring on U.S. highways each year, roadway safety remains one of the most challenging issues facing our country. (1)

Rumble strips are a safety measure used to address one of the most serious types of traffic crashes: a lane departure crash. Rumble strips consist of a set of transverse grooves applied on the shoulder or centerline of a roadway. In Ohio, House Bill 51 was introduced during Ohio’s 133rd General Assembly to require center-line rumble strips (CLRS) for certain highway projects.

Expect More Rumble Strips in the Future. For Good Reasons!

Rumble strips provide a tactile and audible warning to alert inattentive (distracted, drowsy, unfocused, etc.) drivers who may unintentionally drift out of their lane. This warning gives the driver an opportunity to correct their action or reduce speed, which may help them avoid or reduce the severity of a crash.

Rumble strips are an effective and low-cost solution to reduce severe roadway departure crashes. The NCHRP Synthesis 490 shows that adding centerline rumble strips (CLRS) resulted in a 45% reduction in crashes on rural two-lane roads and a 64% reduction on urban two-lane roads. However, while CLRS are an effective strategy for reducing traffic accidents, they add additional stress to an already vulnerable part of pavements, the centerline joint.

OH HB51 Bill Summary

Although HB 51 did not pass, The Ohio Department of Transportation (ODOT) will install rumble strips along the center line for two-way, undivided state highways with a speed limit exceeding 45 miles per hour, as a part of specified highway projects.

While CLRS are an effective strategy for reducing traffic accidents, they add additional stress to an already vulnerable part of pavements, the centerline joint. Rumble strips can reduce the life and performance of the road. Therefore, industry researchers are looking for ways that can help ensure rumble strips can be installed without compromising road life.

Permeability and Cracking are Important Measures of Road Longevity

From the paper titled “Impact of Rumble Strips on Longitudinal Joint Pavement Performance,” the study objectives were to:

- Determine the impact of using VRAM on longitudinal joint performance with and without the addition of rumble strips.

- Evaluate permeability and cracking susceptibility of rumble strips milled into a longitudinal centerline joint.

The conclusions of this study showed:

- In general, there was higher crack resistance values for cores that contained VRAM compared to the sections without VRAM.

- Cores containing VRAM showed similar crack resistance with and without the addition of rumble strips.

- Poorer crack resistance was observed for a joint without VRAM, with or without rumble strips.

- VRAM was effective at reducing permeability.

Previous experience with VRAM indicates when permeability is reduced, air and water infiltration and damage to centerline joints is reduced as well, which can add 3-5 years to the life of a pavement.

To see the full poster and paper, visit the resources tab here: https://thejointsolution.com/resource/

Creating Sustainable Solutions

Sustainability is very important to Asphalt Materials, Heritage Construction + Materials, and The Heritage Group. There are three pillars of sustainability: Economic. Environmental. Social/Safety. Rumble strips are an important initiative to help reduce traffic accidents helping to address the Social / Safety pillar of Sustainability.

How Rumble Strips are Installed

Installing rumble strips on the US-23 project in Wood County, Ohio. (View video below.)

Note:

- VRAM is a Void Reducing Asphalt Membrane

- J-Band® is Asphalt Materials’ VRAM product

Learn More About Asphalt Material's VRAM

J-Band® is a VRAM product from Asphalt Materials, Inc. that was created in the labs of the Heritage Research Group. VRAM has been helping roads last longer since 2002 and has been used in 23 States and The District of Columbia. You can review previous J-Band projects, studies, a lifecycle calculator, studies, and more by visiting other areas of the TheJointSolution website.

Sources:

1 - U.S. Department of Transportation Federal Highway Administration, FHWA Home / Safety / Roadway Departure / Center Line Rumble Strips (T 5040.40)

Editor’s Notes:

HMA is an acronym for Hot Mix Asphalt.

VRAM, Void Reducing Asphalt Membrane, is referred to in Illinois as LJS, Longitudinal Joint Sealant.

J-Band® and CCAP ® are registered trademarks of Asphalt Materials, Inc.

AMIBIND™, AMIBOND™, AMICYCLE™, AMIGUARD™, AMISEAL™ are trademarks of Asphalt Materials, Inc.