Proof already in the pavement.

J-Band brings more to the table than stronger joints. This game-changing technology helps save three of the most important things to any engineer, applicator, or community: time, money and lives.

Protect What Matters Most

Time

Since it’s applied as part of the normal HMA construction process, you don’t need to build in extra time to use J-Band. And motorists in your community won’t be delayed in inconvenient road closures and frustrating traffic congestion.

Money

Using J-Band now paves the way for savings down the road. On the average roadway, every $1 invested in J-Band typically saves agencies $2 in avoided and deferred maintenance costs. This type of investment frees up taxpayer dollars for other important community needs.

Lives

Less repair time means less time crews spend on potentially hazardous maintenance or reconstruction. Likewise, motorists in your community will enjoy a safer, more comfortable ride.

Explore Use Cases

IDOT U.S. Route 51: 20 Years of Joint Performance

The 2002 J-Band application on US-51 was one of J-Band’s first major demo projects. Two years prior, the Illinois Department of Transportation (IDOT), Asphalt Materials, Inc. and Heritage Research Group worked together to find an alternative solution for the recurring issue of longitudinal joint failure, creating J-Band, the Void Reducing Asphalt Membrane – VRAM (a.k.a. Longitudinal Joint Sealant – LJS in Illinois).

For this experimental project just south of Decatur, Illinois, J-Band was sprayed in four 100-ft test sections. These test sections were interspersed with clearly marked control sections, so the joint’s performance could be evaluated year over year.

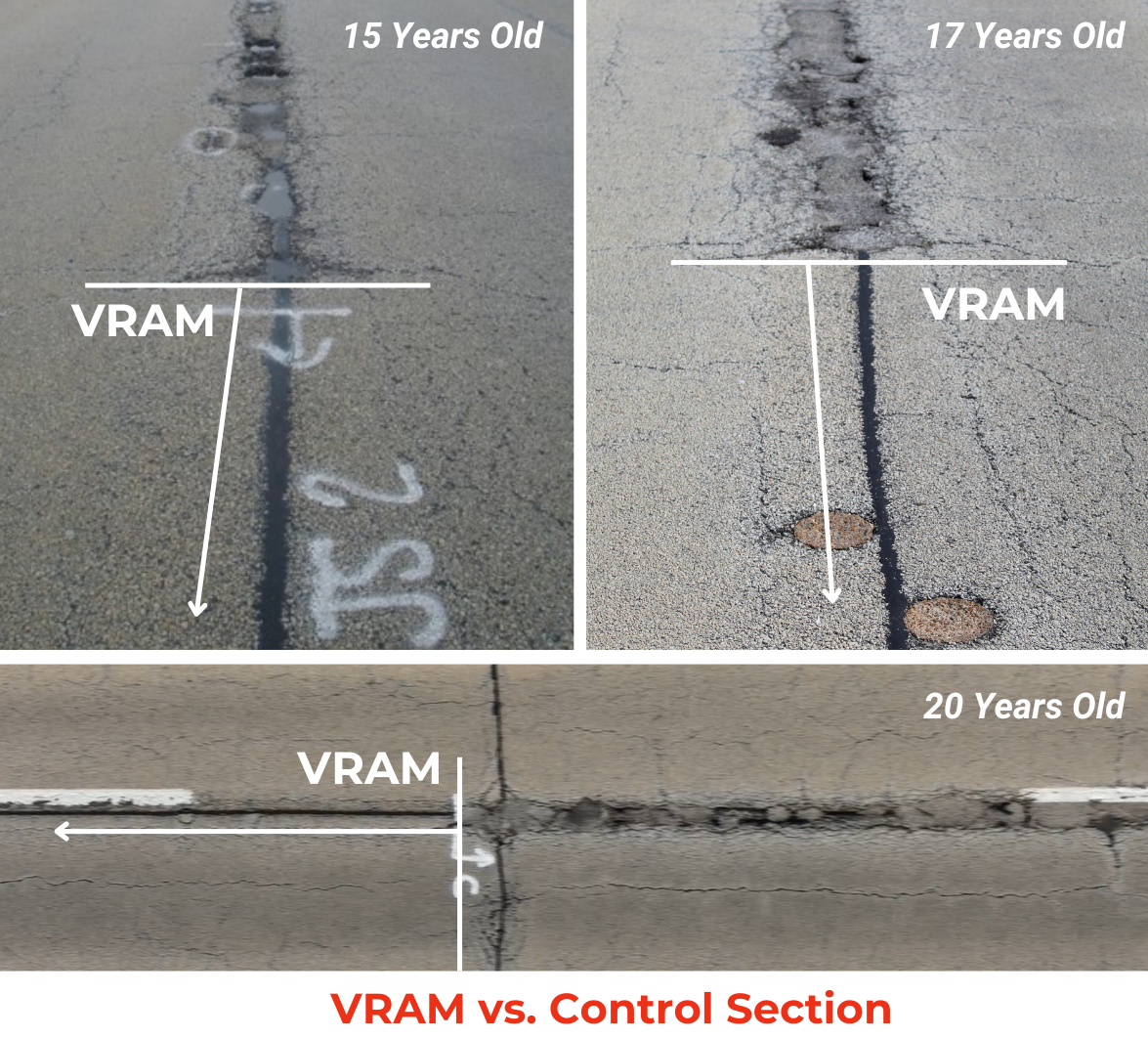

IDOT tested and reviewed this project. Results led the state of Illinois to adopt VRAM/LJS statewide. Even 20 years later, the treated joint stayed in good condition for its age, while the control sections showed severe deterioration. Lab testing of cores taken from the US-51 centerline show that the use of VRAM decreases pavement permeability.

Control vs VRAM application 15, 17, 20 years after initial asphalt paving

ODOT U.S. Route 20: VRAM vs. Control Section Comparison

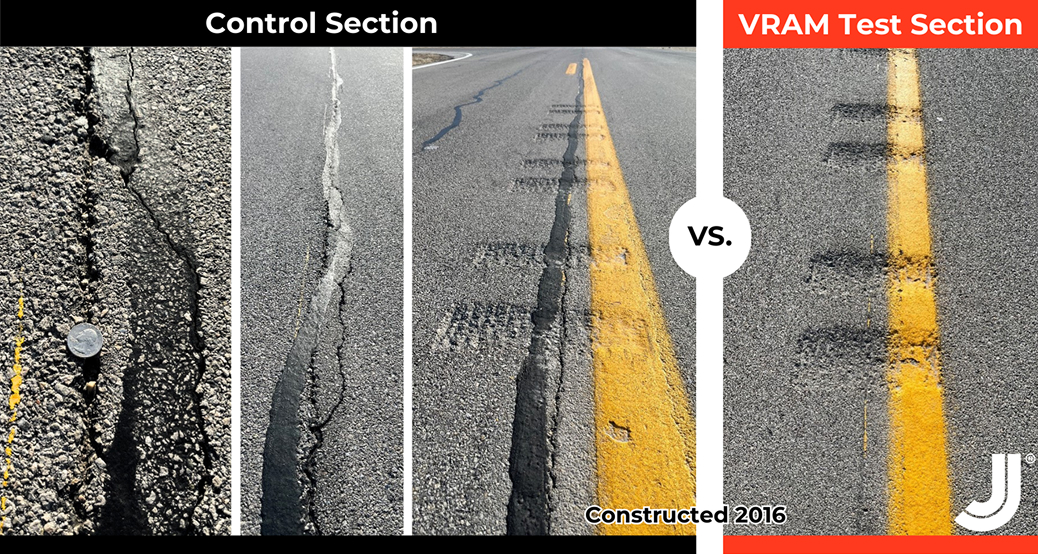

The VRAM test section on US-20 outperformed the control section (without VRAM) by a wide margin when it was reviewed 8 years later. In 2016, VRAM was applied under 4 miles of the centerline longitudinal joint during the resurfacing of this 8-mile Ohio Department of Transportation (ODOT) project.

The control section (without VRAM) began to crack, prompting crack sealing across the entire project. Today, it displays wide cracks throughout. However, on the VRAM test section, no visible cracking developed, even where crack sealing was not performed. The VRAM has filled the air voids in the pavement’s joint area, holding the joint together.

Control vs VRAM Section

IDOT Interstate 72: 2016 Project Stands Strong

On IDOT’s I-72 project between Sangamon and Morgan Counties, the VRAM-reinforced centerline joints have held strong since 2016. The minor surface openings at the joints range from hairline to ½” wide for the length of the project, typical of a VRAM longitudinal joint. The project has required no maintenance or repair.

In 2021, this TRB Research published study calculated that IDOT has seen a 3-5x return on its investment in VRAM (known as Longitudinal Joint Sealant (LJS) in Illinois) based on its cost at the time of installation. This project is an example of these cost savings from delayed maintenance and repair.

Hairline joint opening after 8 years

INDOT State Route 26: 2016 Test Project Results

One of the first projects in Indiana to use J-Band VRAM was an 8-mile Indiana Department of Transportation (INDOT) project in Jay County. In November of 2016, 6,800 linear feet of VRAM were applied at the centerline between the intermediate and surface courses as a test section to monitor VRAM performance. Centerline rumble strips were later milled over the longitudinal joint.

In 2022 and 2023, the condition of the non-VRAM joint required crack sealing. When the project was reviewed in 2024, the control section joint (without VRAM) had 95% cracking ranging from ¼" to ½" wide. In contrast, the VRAM-treated joint showed a 1/8” wide opening for 80% of the test section. J-Band is providing a more durable joint area for this road’s centerline rumble strips.

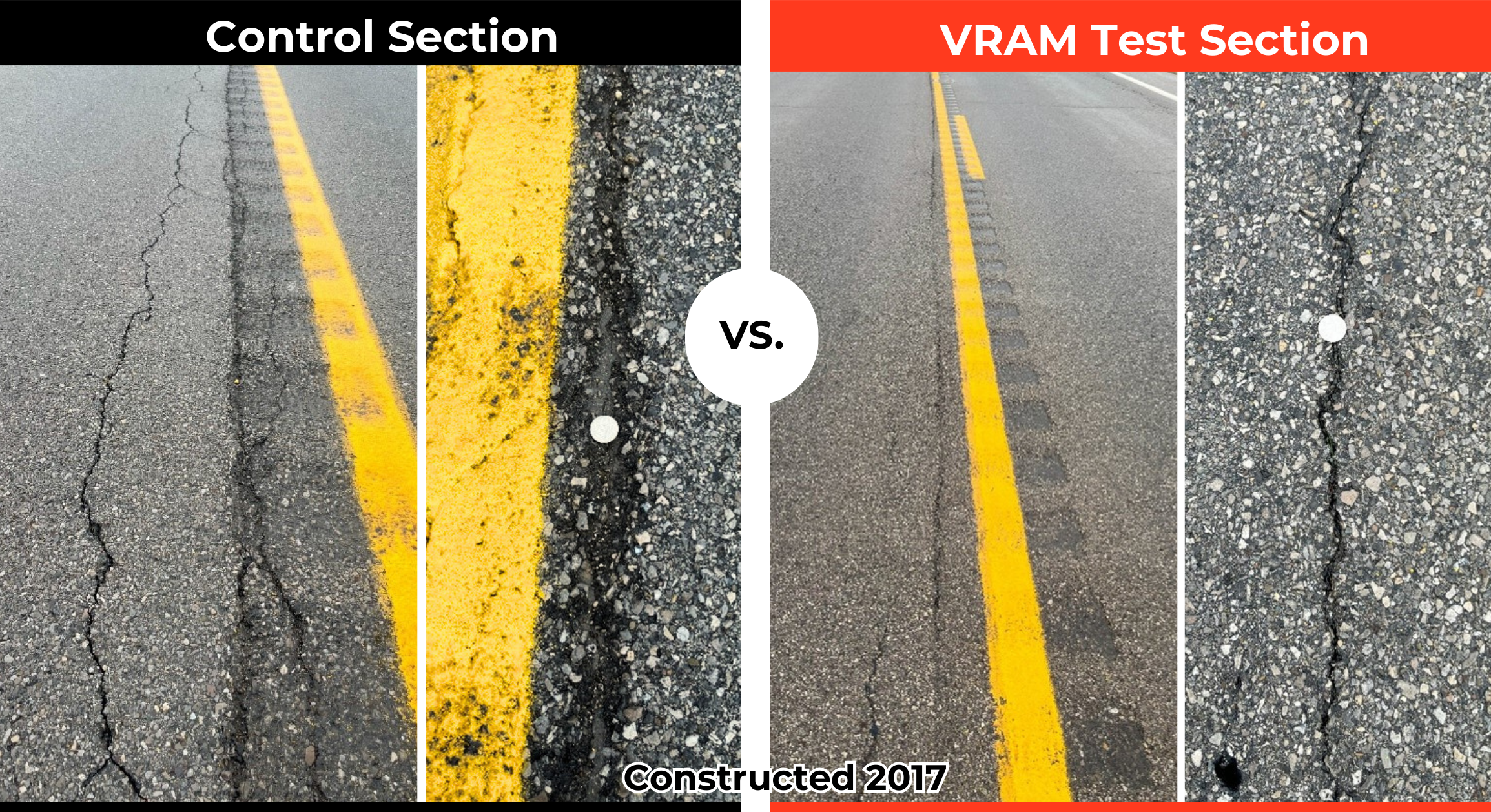

ODOT U.S. Route 250: 2017 Test Project Results

In 2017, the Ohio Department of Transportation (ODOT) let an 8-mile project that tested the capability of VRAM to protect a centerline joint with rumble strips in Wayne County. This project showed an impressive contrast between the control and VRAM test sections when reviewed in 2024. The control (without VRAM) had multiple longitudinal cracks forming along the centerline joint, ranging from ½" to 1 ½” wide. Meanwhile, the VRAM section showed a small percentage of longitudinal cracking, ranging from ¼" to ½" wide.

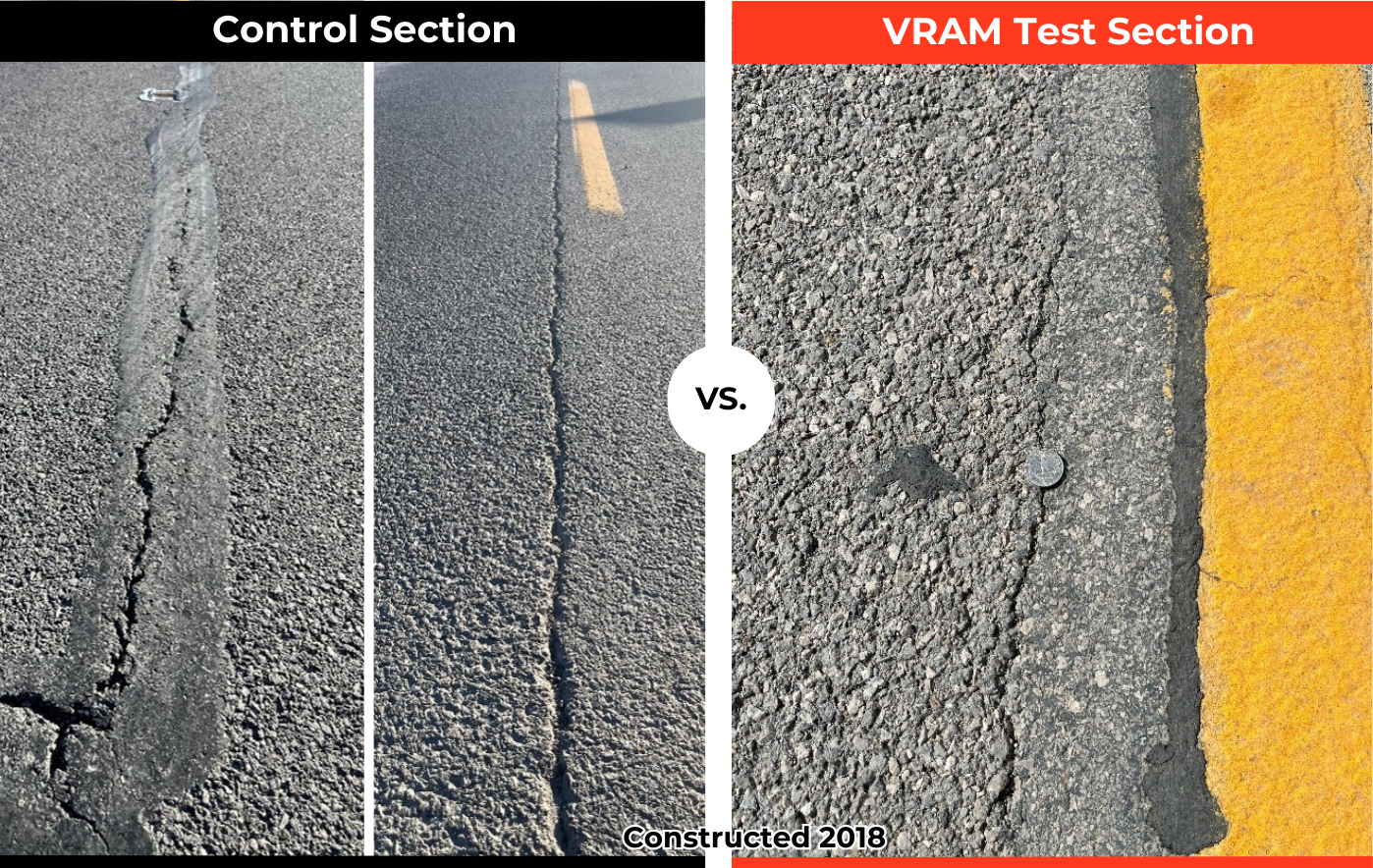

ODOT U.S. Route 6: 2018 Test Project Results

7 years after construction, the VRAM section of this US-6 project has outperformed the control sections. Above the control longitudinal joint, ½” to 1” cracks have emerged throughout 100% of the 8.59-mile section. This prompted ODOT to crack seal the majority of the project. In comparison, the VRAM joint only had controlled 1/8” to 1/4” wide openings.

The contrast between the cracked control section and the VRAM section demonstrates the ability of VRAM to seal longitudinal joints from the bottom up. Instead of worrying about maintenance and early reconstruction, agencies can rely on the power of VRAM to extend the life of the longitudinal joint 3-5 years beyond the expected 15 years for joints.

Asphalt-Concrete Curbs and Lanes

Getting a good bond between hot mix asphalt (HMA) and concrete interfaces is challenging but critical for long-lasting pavement. To combat this issue, many agencies are turning to VRAM to reinforce these vulnerable edges. VRAM does more than just seal the asphalt to the concrete curb. It reduces pavement permeability at the mat’s edge, protecting it from air and water intrusion.

Why the curb focus? Water often pools along curbs, and these areas are notoriously hard to compact and seal properly. The use of traditional tack coats during the paving process does not create a robust enough bond at the concrete-HMA joint. Differences in the properties of the two materials (stiffness, expansion coefficients, etc.), as well as high pavement permeability, lead to joint distress that is often sealed with a crack filler. J-Band VRAM provides a superior bond and fills air voids in the mat above, reducing permeability concerns. This dual purpose creates a stronger, more resilient joint.

Trench Mill & Fill and Slot Paving

When crack sealing at longitudinal joints is no longer sufficient, agencies can address severe joint damage with a trench mill & fill: milling out the joint area and filling it with hot mix asphalt (slot paving) followed by compaction. However, this results in two new joints that will continue to fail faster than the remaining pavement areas.

This is where a VRAM can help. The material has repeatedly demonstrated its ability to extend the life of longitudinal joints for an additional 3-5 years by filling air voids that allow for destructive water intrusion. While a VRAM is typically applied at the time of full lane re-paving, slot paving offers an opportunity to install a VRAM under the trench fill, reinforcing the new joints so they last as long as the rest of the new pavement.

The Montana DOT used VRAM to reinforce 16 miles of slot paving on Montana Highway 200. By adding VRAM, the life expectancy of the slot paving section is projected to extend from sub-5 years to 10+ years, at which time the VRAM has provided maintenance savings more than double its cost.

Notched Wedge Paving Joints

Over the last two decades, the use of a notched-wedge geometry on the unconfined paving joint has become a common approach for agencies to address the safety concerns of live traffic crossing the paving joint. Today, many states, including Iowa, Montana, Connecticut, Texas, Wisconsin, and Michigan (where it’s known as a “Michigan joint”), regularly use variations of this technique when the overlay is greater than 1.5" thick and the road is staying open to traffic.

Despite the safety benefits of notched-wedge joints, this method does present challenges. Forward-thinking agencies are using VRAM to help ensure lasting durability of the finished joint by addressing the root cause of joint failure—permeability created by high air voids.