About this project:

This Void Reducing Asphalt Membrane (VRAM) project took place on June 28th in Sheboygan Falls, Wisconsin. This two-lane highway goes through a commercial warehouse section and a subdivision. The county is designating VRAM for not only the centerline, but also along the edges of roadway where new widening has been placed next to the edge of the existing road.

Protection of the longitudinal joints is very important and by placing VRAM at the time of construction has been shown to be a great insurance policy against future maintenance costs, which are avoided by using VRAM.

The centerline and edge line VRAM applications were both targeted at 18” wide and placed on milled surfaces.

The VRAM applicator for this project was Pro Tack, and the prime paving contractor was Sheboygan County.

Paving started shortly after the placement of the VRAM. The paving train consisted of a Cat 100F Paver, an IR DD-90 steel drum roller, and a Cat 434D steel drum roller. All the rolling was done in static mode with the DD-90 as breakdown and the small Cat as the finish roller.

Both counties worked extremely well together and displayed great teamwork to install a good-looking surface course.

Why is it important to protect the centerline?

Longitudinal joints are typically the first place of the pavement that begins to fail. With their inherently lower density, and exposure to natural elements such as water and air, longitudinal joints fail. Examples of this include the cracking, raveling, and potholing of the pavement. Investing in ways to produce longer-lasting roads becomes even more urgent when it is known that longitudinal joints are susceptible to damage and highly vulnerable.

How to solve this dilemma.

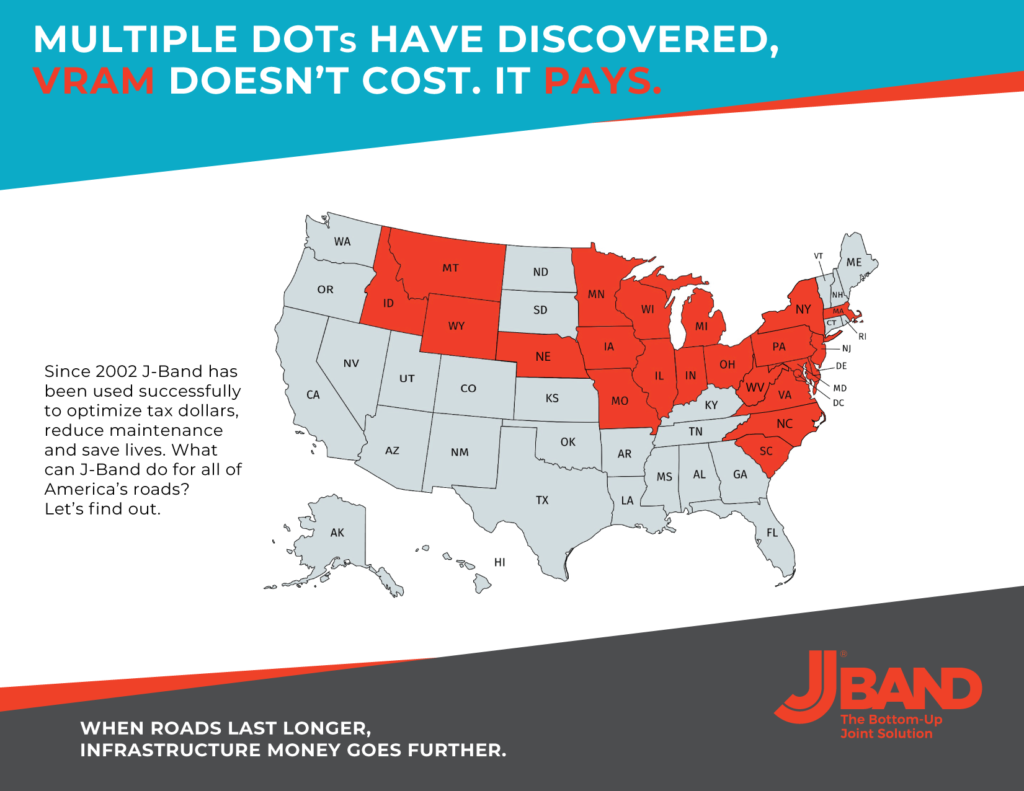

Void Reducing Asphalt Membrane (VRAM) projects have shown to be an answer to this problem. VRAM is a materials approach (it is mostly asphalt) and has been proven to be successful in protecting the centerline joint of the road. VRAM has been utilized in 22 states and counting as of July 2022.

To the right, a map of J-Band projects that have been applied across the United States, as of July 29, 2022 is displayed.

What is VRAM?

VRAM is applied at the time of construction under the surface of the road. This treatment will ultimately reduce the permeability of this crucial part of the road. Once the placement of the hot mix asphalt is complete, the heat causes the VRAM to migrate upwards, resulting in the filling of voids and reducing permeability.

With the additional application of VRAM, roads have been proven to last longer. J-Band®, Asphalt Materials’, VRAM is a breakthrough discovery that helps roads last up to 5 years longer and delivers a return on investment of 3 to 5 times its cost.

Helping Federal, State and Local Agencies

State and local agencies are being called upon to use of Data-Driven Programs and Policies. It is more important than ever to manage data and to provide objective, reliable, timely, and important information to support decision-making, transparency, and accountability. There have been several studies conducted on VRAM that help support its current and future use as a way to responsibly steward the public’s resources. You can find these studies on our website at: https://thejointsolution.com/resource/studies/

Evidence-Based Budgeting is another area of importance for agencies. In an effort to be more inclusive and transparent, it is important to educate the public about the value of their transportation investments. RAP, or Reclaimed Asphalt Pavement is a strategy most agencies employ. VRAM is another. An investment in VRAM is an investment with a proven Return on Investment (ROI). Specifically an Indiana DOT life cycle cost analysis (LCCA) showed that an investment of $12.5M in VRAM would result in a $39M savings, which is approximately 3:1 ROI. To learn more about LCCA and our calculator visit this tool on our website: https://thejointsolution.com/calculator/

To learn more about J-Band®, Asphalt Materials’ VRAM, email: Marketing@Asphalt-Materials.com.

VRAM has been helping roads last longer since 2002 and has been used in 22 States and The District of Columbia. J-Band® is a VRAM product from Asphalt Materials, Inc. that was created in the labs of the Heritage Research Group.

Editor’s Notes: VRAM, Void Reducing Asphalt Membrane, is referred to in Illinois as LJS, Longitudinal Joint Sealant.