The NCAT Test Track

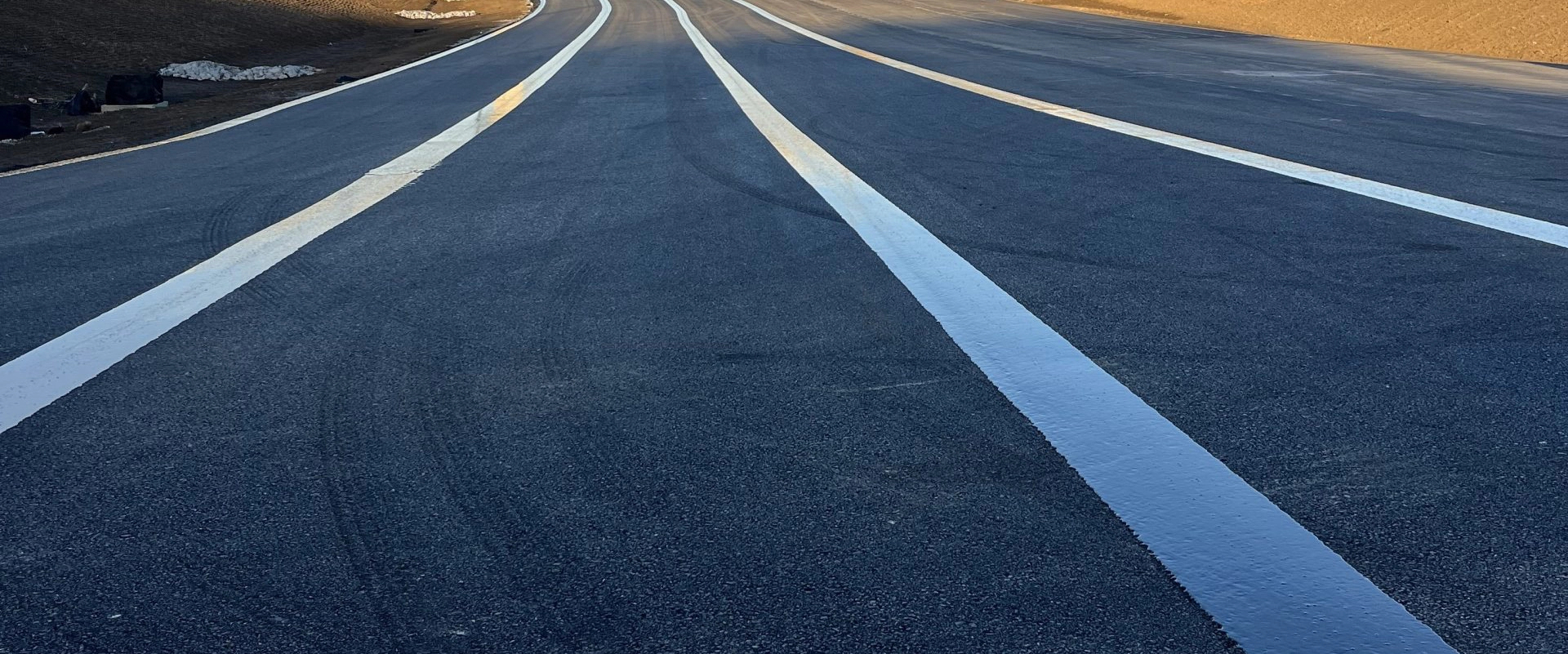

The National Center for Asphalt Technology (NCAT) Test Track at Auburn University is a proving ground for asphalt pavements. Made up of a 1.7-mile oval, the Test Track is divided into 200-foot test sections to create a real-world laboratory for innovative paving techniques and products. In this unique environment, the NCAT fleet can simulate the equivalent of several years—often over a decade—of interstate-like traffic within just two years. It is one of the only full-scale accelerated pavement testing facilities worldwide.

NCAT’s work furthers the industry’s ability to provide safe, durable, sustainable and economical pavements. Through partnerships with the Federal Highway Administration, State DOTs and the highway construction industry, NCAT’s research has been used to improve material characteristics, specifications and mix design policy.

VRAM Technology

Void reducing asphalt membrane (VRAM) is an asphalt innovation designed to solve the ongoing issue of longitudinal joint failure. The product uniquely fills air voids in longitudinal joints from the bottom up. J-Band®, the premier VRAM, has proven itself as a pavement preservation tool through long-standing projects and previous lab and field studies, leading to its use in 25+ states.

As a leader in the industry, NCAT was eager to test this innovative asphalt product. VRAM was applied for the first time on the renowned NCAT Test Track on a hot and sunny September day in Opelika, Alabama.

Project Details

- Owner: NCAT Test Track

- Prime Paving Contractor: East Alabama Paving Co.

- VRAM Applicator: Cimline

- Location: Opelika, Alabama, Test cell S13

- Date Constructed: September 18, 2024

VRAM Application

Test cell S13 was milled out by 1.5 inches on the inside driving lane and exit lane prior to the VRAM application. The sections were swept before VRAM was sprayed by a Climline MA4 original longitudinal joint sealer along the inside edges of the milled lanes. The MA4 sprayer was pulled by a truck.

Personnel present were Todd Thomas from Asphalt Materials, Inc. (AMI), Bill Ganger of Cimline who operated the MA4, and Nathan Moore the Assistant Director for Test Track Research. The application targeted a 0.95 lb./ft. rate and 9 inches wide. Paving began the next day.

Paving Observations

On September 19, East Alabama Paving Company laid a 4.75-mm NMAS fine-graded mix (according to the VRAM construction guidelines) on the inside driving lane and exit lane, covering the VRAM. The heat from the hot mix and the pressure of the rolling operation cause VRAM to migrate upward through the mix, filling air voids and reducing permeability at the joint. Personal present included Hallie from Associated Asphalt, an Ergon Company, who was onsite as a representative of the VRAM.

Test cell S13, along with other new test cells with VRAM, will be carefully monitored over time. VRAM has the ability to protect longitudinal joints from moisture intrusion, thereby controlling the variable of joint deterioration in each test section’s pavement performance. By filling the air voids in these longitudinal joints, VRAM decreases pavement permeability and increases pavement relative density around the joint. When the life of the joint is extended, the performance of the entire pavement is improved.

Nathan Moore, Assistant Director for Test Track Research says, “We’re looking forward to using VRAM again on the NCAT Test Track as a preservation tool to improve future longitudinal joints.”

As NCAT continues to lead the industry through asphalt pavement technology research, VRAM is prepared to support safe, durable and sustainable pavements.

For a closer look at more projects that have incorporated a VRAM during construction, you can explore our interactive map here.

Editor’s Notes:

J-Band® was created in the labs of the Heritage Research Group (HRG) and is a product of Asphalt Materials, Inc. J-Band® is a registered trademark of Asphalt Materials, Inc.