About this project:

A Void Reducing Asphalt Membrane, (VRAM), project took place on June 13 in Warrick County, Indiana. VRAM was placed on I-64 starting east of SR-61 and continuing to west of SR-161. The VRAM application was applied on the centerline of the pavement, as this is the most vulnerable portion of the pavement. The VRAM applicator and prime paving contractor for this project was E/B Paving.

The paving process began early in the morning with paving in the eastbound lane heading westward. The paving with hot mix asphalt (HMA) began after the VRAM was placed. Paving equipment used for this project included a RoadTec SB2500D shuttle buggy, a CAT 1000D grade control paver, a HAMM HD120i steel drum roller, a CAT CB13 steel drum roller and a CAT 634C steel drum roller as the finish roller. The breakdown rollers were working middle out with 5 passes in vibratory and 1 pass static. The finish roller worked in static mode.

VRAM – A Materials Approach for Solving Pavements’ Joint Issues

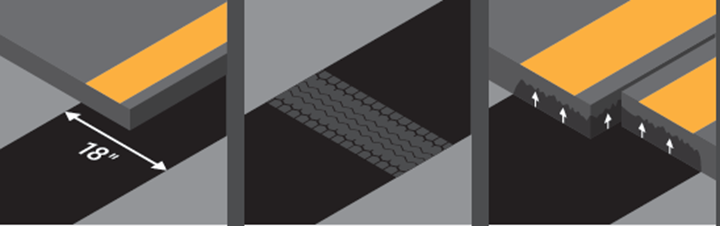

When VRAM is applied at the time of construction, directly under the asphalt surface, it will reduce the permeability in this highly critical area of the road. Once the placement of the hot mix asphalt is completed, heat and pressure from the paving rollers will cause the VRAM to migrate upwards and fill air voids. This process will reduce the permeability of the pavement.

Editor’s Notes:

- Centerline joints and longitudinal joints are often used interchangeably in describing the area of the pavement where two sections come together.

- VRAM, Void Reducing Asphalt Membrane is referred to in Illinois as LJS, Longitudinal Joint Sealant.

- Depending on the situation VRAM can be sprayed at different width’s. It should be noted that 18” is a typical application width for centerline applications.

J-Band® is a VRAM product of Asphalt Materials, Inc. and was created in the labs of The Heritage Research Group.

J-Band® and CCAP® are registered trademarks of Asphalt Materials, Inc. AMIBIND™, AMIBOND™, AMICYCLE™, AMIGUARD™, AMISEAL™ are trademarks of Asphalt Materials, Inc.