VRAM Helps Longitudinal Joints Last Longer

Written by Naarah Holloway

Did you know that the first part of the pavement to fail is the longitudinal joint? This joint is susceptible to damage caused by water and air. When water and air enter deep into the joint, it causes the joint to deteriorate with cracks and eventually potholes. When the longitudinal joint fails, the rest of the road will also begin to deteriorate. This creates the need for additional road maintenance and repairs.

Unlike other treatments, VRAM, a Void Reducing Asphalt Membrane significantly reduces air voids in longitudinal joints. VRAM is a materials approach, applied prior to paving under the eventual location of the longitudinal joint. It migrates upward, fills voids, and reduces permeability as the hot mix is installed on top of it. Since 2002, this approach has improved the performance of centerline joints and entire pavements in more than 23 states.

VRAM is utilized in projects across the nation to create longer-lasting, safer roads. Our team works with agencies to construct projects and measure the impact that VRAM has in different circumstances across many states. Each year, many of these projects undergo an annual review. This particular review was in Edgerton, OH on a project that took place in 2018.

2022 Review of a 2018 Project

- Owner: ODOT

- Applicator: SCI

- Prime Paving Contractor: Gerken

- Location: US-6, Edgerton, Ohio (Williams County)

- Date Constructed: 2018

- Date Reviewed: 11-28-2022

2022 Project Observations

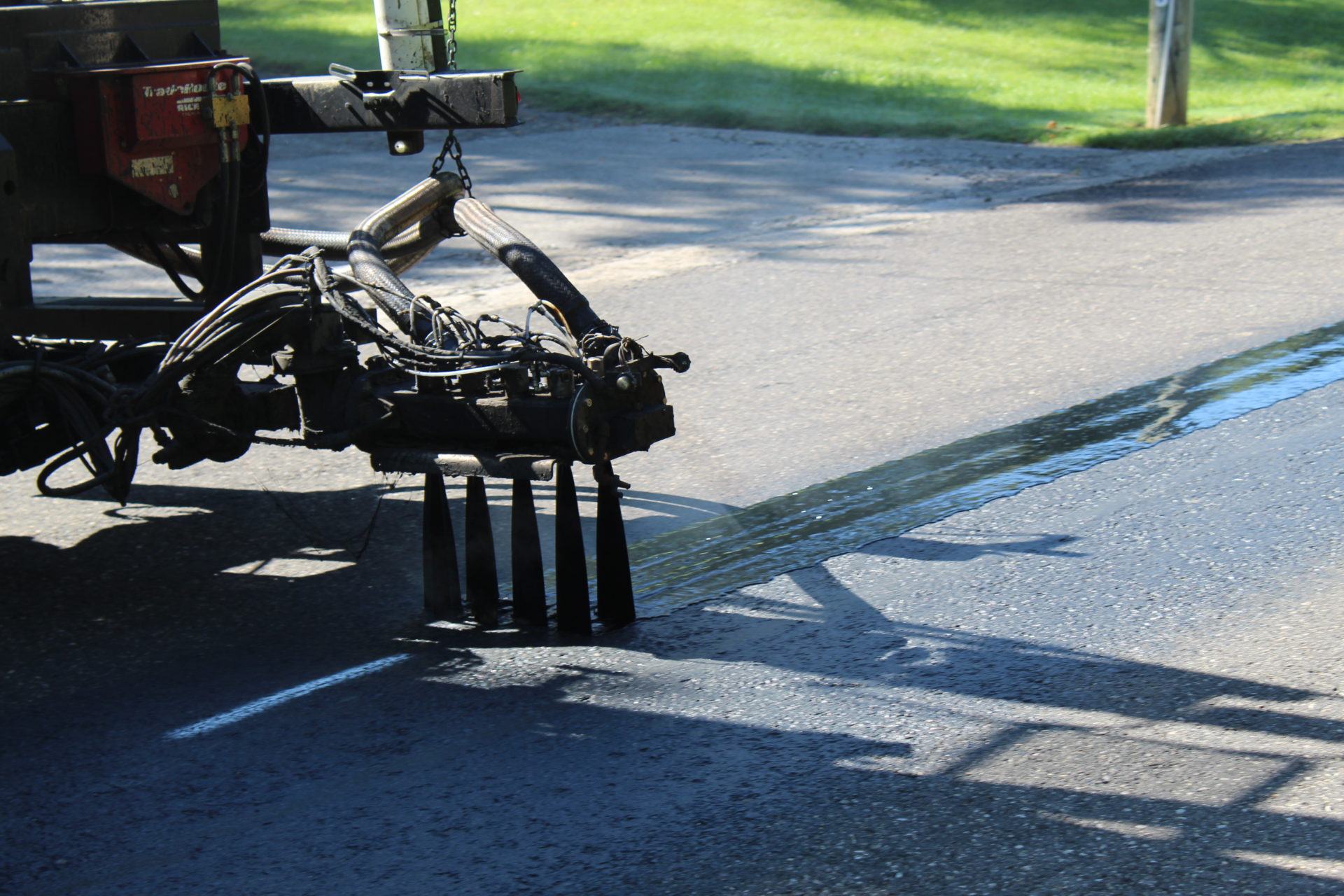

Asphalt Materials Field Support Engineer Chad Crosby reviewed the Williams County project. This section of US-6 is a two-lane road with reflective pavement markers (RPM). The project assessment and images from this review are shown below.

This entire project has been cracked sealed. However, the VRAM portion of the project did not need to be sealed and was performing as expected, very well.

Test Section (With VRAM)

There is a small joint opening visible within the test section that utilized VRAM. In about 80% of the test section, there is a very slight opening at the joint that measures approximately 1/8”.

Control Section (Without VRAM)

The control section did not use VRAM and there is a visible joint opening through the crack seal of ½” compared to the small 1/8” joint opening observed in the test section. The control section had joint openings throughout with widths between ½” – 1” which were even noticeable through the sealant. The control section also has sections with surface openings coming off from the centerline.

VRAM Still Protecting the Centerline

This project assessment found that the VRAM continues to protect the centerline joint. Even though there is a joint opening seen in 80% of the test area, it is only a very narrow ⅛” width.

Pavement markings typically crack after one winter, but it reinforces why the centerline is the most important and expensive section of the road. Agencies can make several different investments at or near the center of a road such as striping, reflective pavement markers (RPMs), and rumble strips. If the underlying pavement deteriorates after these investments have been made, the maintenance costs for the repairs of these treatments can become a significant additional cost. Utilizing VRAM can help protect these investments.

Fortunately, utilizing a VRAM, such as J-Band® has been proven to protect the most valuable and expensive 18″ of roadways: the centerline. J-Band® is a Void Reducing Asphalt Membrane (VRAM) that has been used for over 20 years. The VRAM significantly reduces air voids and connected voids in longitudinal joints. J-Band® is applied before paving under the eventual location of the longitudinal joint. VRAM migrates upward after the hot mix is placed, literally filling voids from the bottom up. When voids are filled with VRAM permeability is reduced.

Explore our interactive calculator and learn more about how longer-lasting roads save time, money and lives here.

Since 1956

Longer-Lasting, Safer Roads

At Asphalt Materials, we understand that longitudinal joint deterioration has long been a problem for engineers, applicators, and the communities we live in. VRAM was developed to help create longer-lasting, safer roads through a collaboration between state transportation agencies, industry experts, and the laboratories at Heritage Research Group.

Unlike other treatments, VRAM is a materials approach that significantly reduces air voids in longitudinal joints. J-Band® is Asphalt Materials’ VRAM product. J-Band as a materials approach, is applied prior to paving under the eventual location of the longitudinal joint. As the hot mix asphalt (HMA) is installed on top of J-Band, it migrates upward, fills voids, and reduces permeability. Since 2002, this approach has improved the performance of centerline joints and entire pavements in more than 22 states.

J-Band® is a product of Asphalt Materials, Inc. and was created in the labs of Heritage Research Group. To learn more about J-Band, or to connect with our team, you can email us at: Marketing@Asphalt-Materials.com.

Editor’s Notes:

J-Band®, CCAP® and T-Bond® are registered trademarks of Asphalt Materials, Inc. AMIBIND™, AMIBOND™, AMICYCLE™, AMIGUARD™ and AMISEAL™ are trademarks of Asphalt Materials, Inc.

J-Band® was created in the labs of the Heritage Research Group (HRG) and is a product of Asphalt Materials, Inc. (AMI). To learn more about J-Band, visit www.thejointsolution.com.