After beginning in the Midwest in 2002, VRAM has now been used in 23 states and The District of Columbia. VRAM stands for Void-Reducing Asphalt Membrane. Pavement maintenance due to longitudinal joint cracking has long been a problem for not only road construction engineers and applicators but also drivers. VRAM fills air voids and significantly reduces permeability at the longitudinal joint and the area on each side of the joint.

Recently, West Virginia’s Division of Highways (WVDOH) has encountered the issue of high permeability at the longitudinal joint and subsequent failure of their asphalt pavements. Longitudinal joint issues can arise when hot and cold lanes fail to adequately bond with one another. WVDOH is responsible for constructing, reconstructing, and maintaining more than 35,000 miles of state roads. So, it is evident that the issue of high permeability can create big, expensive problems for their division of highways and taxpayers.

VRAM Background Information

In a proactive approach to extend the life of the longitudinal joint, a VRAM can be integrated into the paving process. Many agencies across the United States have already implemented this prior to the final paving process. VRAM is typically applied at an 18” width across the centerline. Hot mix asphalt is applied on top of VRAM, which activates the material, helping it migrate upward filling the voids, and reducing permeability. Therefore, to resolve such issues, the WVDOH began a pilot project to use a VRAM application with Associated Asphalt’s VRAM which is called J-Band®.

Project Details

The West Virginia pilot project began on October 15, 2021, in Parkersburg, West Virginia on US-50. This was an 18-month project to test the durability of VRAM. To test the product, there was a control section of the road and a test section where VRAM would be applied. The Eastbound section of the road was considered the control section and runs from the 7th Street exit to the bridge. The J-Band area ran Westbound from the 7th Street ramp to the light pole just east of Staunton Turnpike. The J-Band sections were 1 mile in each direction while the control sections were approximately 0.22 miles in each direction. The application rate was 1.80 lb./ft at an 18” width. During the actual paving process, four cores were pulled from the J-Band section, and three cores were pulled from the control area. These cores were then sent to Rutgers University for evaluation. You can view the information from Rutgers in a separate article here: https://thejointsolution.com/cait-evaluates-performance-of-j-band/

Jobsite Evaluation

On May 25, 2023, the WVDOH set up a lane closure on both the Eastbound and Westbound lanes of US-50. The closure took place around 10:00 am and allowed members of a team to walk and review the 18-month project. Attending this review was Vincent Allison (WVDOH), Eric Lough (WVDOH), David Powers (Associated Asphalt), and representatives from the WVDOH District Three.

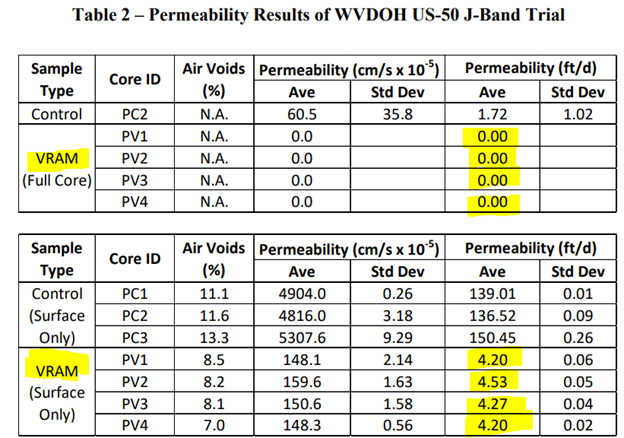

The team began to walk on the Westbound Lane of US 50 to evaluate the upkeep of the road with the VRAM application. It was noted that both the Westbound and Eastbound portions of the road looked similar. They showed a slight opening at the top, which was to be expected and was not a concern since J-Band is not used to prevent slight openings in the joint. The purpose of J-Band is to fill the voids in the longitudinal joint from the bottom up with an asphalt material, making the joint less permeable. Rutgers University investigated and discovered that the J-Band section of US-50 was 33x less permeable than the control section. You can view this information in more detail under Table 2 -Permeability Results of WVDOH US-50 J-Band Trial.

After the team viewed the J-Band section of US-50, they then proceeded to view the control section. The team noticed that the control section of the longitudinal joint was noticeably wider than the J-Band section of the entire project. The control section was sealed with PG64-22 after the original paving that occurred in October 2021. The J-Band section has yet to be sealed.

Conclusion

The Rutgers University team concluded that the air voids in the VRAM section were significantly lower compared to the control section (7.9% to 12.0%). The application of the J-Band product also significantly reduced the permeability of the compacted asphalt. On average, the permeability of the J-Band section was 33 times lower than the controlled section. When permeability testing was conducted using the entire core that was provided, the sections of VRAM were determined to be impermeable. This indicates that the VRAM seals off the underlying asphalt layers below the longitudinal joint area, also providing protection to the underlying layers.

The J-Band (VRAM) section had overall decreased permeability, improved the opening resistance of the joint, lowered air voids, and better improved joint performance. Based on the data collected by the Rutgers team, it would suggest that the performance of the VRAM on US-50 is a much better process than the control section.

WVDOH along with Associated Asphalt have scheduled future sight reviews for October of 2023 and May of 2024. This will help them to continue to evaluate the performance of the longitudinal joints on the US-50 project.