On September 22, 2022, Rutgers University’s Department of Civil and Environmental Engineering and their Center for Advanced Infrastructure and Transportation (CAIT®) conducted a study on the Pennsylvania Turnpike evaluating the performance of J-Band®.

About the Project

A Void Reducing Asphalt Membrane (VRAM) project was performed on the Pennsylvania Turnpike between mileposts 94 and 99. This project and subsequent tests were done to evaluate the functional and structural performance of the longitudinal joint in a control area (without J-Band®) and a test area where J-Band® was applied.

J-Band®, Asphalt Material’s VRAM product, has a performance track record, dating back to 2002. J-Band was created in the labs of The Heritage Research Group in collaboration with state and local agencies and industry experts. One of the primary reasons J-Band is used in economics. When roads last longer, infrastructure dollars go further.

In this project, J-Band was applied at a rate of 1.50 lb./ft. In order to achieve the desired surface layer thickness of 2.0 inches, a 12.5 mm nominal maximum aggregate size (NMAS) stone matrix asphalt (SMA) was used. A 19 mm NMAS was positioned at the target thickness of 3.0 inches before the SMA.

Testing the Performance of the Longitudinal Joint

To test the performance of the longitudinal joint, Rutgers University received four (4) field cores from the J-Band test section and three (3) cores from the control section. The testing involved measuring the permeability of the core, air voids, in addition to cracking and resistance using the IDEAL-CT Index test procedure.

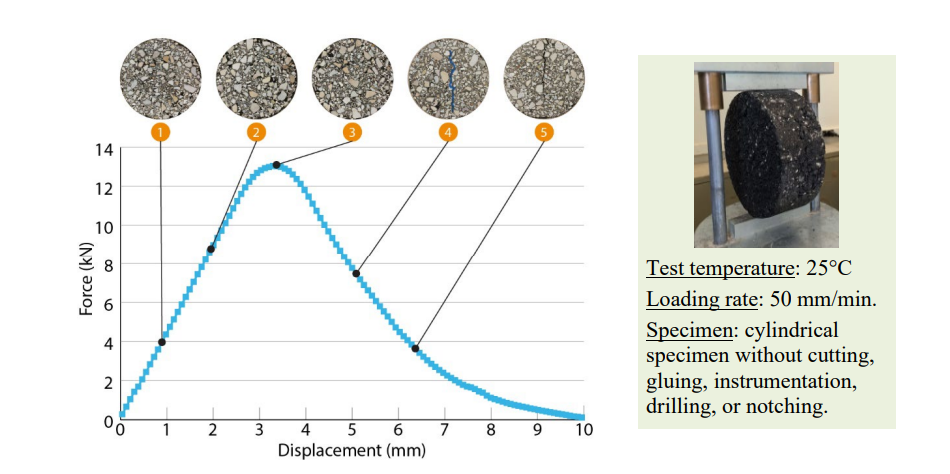

The IDEAL-CT Index test is an indirect tension test that uses a fracture mechanics-based parameter to assess the cracking propensity of asphalt mixtures.

The IDEAL-CT is carried out at room temperature of 25 degrees Celsius using cylindrical specimens at a loading rate of 50 mm/min in terms of crosshead displacement. It is identical to the conventional indirect tensile strength test. It is possible to test cylindrical specimens of any size with different diameters (100 or 150 mm) and thicknesses (38, 50, 62, 75 mm, etc.).

Rutgers University Results

- The permeability of the asphalt at the longitudinal joint was dramatically decreased by the application of the J-Band product. The J-Band treated longitudinal joint had permeability that was, on average, twenty-four (24) times slower than the untreated longitudinal joint.

- The J-Band sections were found to be impermeable when permeability testing was done utilizing the complete given core (12.5mm SMA + J-Band + 19mm HMA). This clearly shows that the J-Band seals off the underlying asphalt layers beneath the longitudinal joint area.

- For the 12.5mm SMA surface course with the butt joint longitudinal joint construction, the air void assessment showed that the Control section had somewhat more compressed air voids than the VRAM section (6.5% vs. 5.2%, respectively).

To read more, you can find the entire study here.

J-Band is an industry-leading VRAM that has been helping fill

longitudinal voids in pavements since 2002.

Using the IDEAL-CT Index test procedure, it was found that applying the J-Band product greatly increased the longitudinal joint’s cracking resistance. When compared to the IDEAL-CT Index values obtained from the Control core, the application of the J-Band product enhanced the longitudinal joint’s IDEAL-CT Index by more than four times.

When built using butt joint techniques on this project, the Pennsylvania Turnpike MP 94 to 99 (Western PA) J-Band longitudinal joint section should perform better than the conventional longitudinal joint areas due to the reduction in air voids, significant decrease in permeability, and increased cracking resistance as measured by the IDEAL-CT Index of the longitudinal joint.

Centerline and longitudinal joints are often used interchangeably in describing the pavement area where two paved sections come together.

In Illinois, VRAM, Void Reducing Asphalt Membrane is referred to as LJS, Longitudinal Joint Sealant.

Depending on the situation VRAM can be sprayed at different widths. It should be noted that 18” is a typical application width for centerline applications.

J-Band® is a VRAM product of Asphalt Materials, Inc. that was created in the labs of The Heritage Research Group.

J-Band®, CCAP® and T-Bond® are registered trademarks of Asphalt Materials, Inc.

AMIBIND™, AMIBOND™, AMICYCLE™, AMIGUARD™ and AMISEAL™ are trademarks of Asphalt Materials, Inc.