This article explores why nuclear density gauge testing may not be accurate or necessary when J-Band® Void Reducing Asphalt Membrane (VRAM) is applied beneath longitudinal joints.

Why Measure Density?

Density is measured during asphalt pavement construction because it is a strong indicator of pavement performance, even though other measurements also contribute to assessing pavement durability. Pavement density is the weight of the pavement material per unit volume, achieved through compaction to make the pavement stronger. Density can be measured by coring (most accurate but time-intensive and destructive) or through portable measurement devices, like the common non-destructive nuclear density gauge. Non-destructive testing gauges can be used for quick consistency checks and absolute density measurement — where they need to be calibrated to a known density value for accuracy.

No matter how density is being measured, it is ultimately an indicator of pavement compaction, which serves to decrease permeability and rutting. Higher density (fewer air voids) leads to less permeability, which means water and air cannot intrude as easily. Impermeability reduces moisture damage and oxidation, which causes cracking.

Density at the Longitudinal Joint

The weakest part of an asphalt pavement is often the longitudinal joint, where it is difficult to achieve proper compaction. Because longitudinal joints have more air voids compared to the rest of the mat, they are more susceptible to water intrusion. Besides proper construction and compaction, there is another way to build impermeable pavements — using a Void Reducing Asphalt Membrane (VRAM).

How does VRAM work?

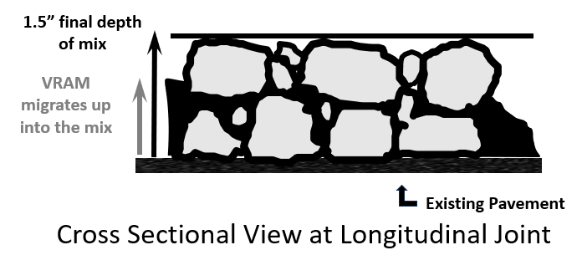

VRAM is a highly polymer-modified asphalt used by DOTs and engineers to extend the life of asphalt longitudinal joints by filling air voids in the pavement structure from the bottom up.

When VRAM is applied under the joint area, prior to paving the wearing course, this unique product migrates up into the mat to fill air voids—increasing the asphalt content of the pavement.

VRAM Benefits:

- Fills air voids

- Decreases permeability

- Reduces water intrusion

- Extends joint life

VRAM and Joint Density

Because VRAM increases the asphalt content of the mix, it may appear to lower the density readings of a nuclear density gauge that is calibrated to the production mix. However, VRAM actually lowers pavement permeability by filling air voids, making the joint impermeable to water — the ultimate goal of proper compaction. The ability of VRAM to extend joint life has been proven across hundreds of projects and in lab settings.

Transportation Research Board (TRB) published I-FIT testing that shows that longitudinal joints with VRAM have significantly better cracking resistance than joints without VRAM. The research also concludes that VRAM is effective in mitigating permeability concerns (Source).

The 15-year-old pavements in the TRB study had joints compacted with the same effort as the rest of the pavement mat. When compaction is the same, centerline density testing can be waived for VRAM joints. State agency VRAM specifications state, “The area 1.0 ft on either side of the longitudinal joint will be excluded from density measurement and pay adjustment.”

The Illinois Department of Transportation (IDOT) was the first adopter of VRAM, known as Longitudinal Joint Sealant (LJS) in Illinois. They determined that, “When the LJS is specified, the longitudinal joint density testing will not be required on the joint(s) with the LJS.”

Explore the proof behind waiving density testing here.

Understanding Why Density Testing is Not Necessary for VRAM Joints

Terms:

- Gmm: Theoretical maximum specific gravity is the maximum amount the mixture can be compacted with no air. This value is used as a baseline to compare the mix once compacted in the field.

- [Gmm] x [density of water] = Theoretical maximum density (TMD) or “Rice” density, used to calculate air void characteristics of an asphalt mix to ensure proper pavement compaction and performance.

- Gmb: Bulk specific gravity of a compacted asphalt mix measures the density of the material, including the volume of the pores that are permeable to water. This value can be used for performance testing and to calculate in-place density and air voids—a common pay factor for agencies.

During the mix design phase, the optimum asphalt content is selected. Based on this, the mixture’s bulk specific gravity (Gmb) and maximum specific gravity (Gmm) are determined. In traditional paving, a nuclear density gauge is calibrated using the asphalt mixture and the plant-produced, lab-measured maximum specific gravity (Gmm). The nuclear density gauge is placed on the pavement to take readings and compare them to the input values.

For asphalt paving projects with VRAM, the volume of the VRAM is significant, almost doubling the asphalt content of the mix placed over it. Because the nuclear gauge is calibrated for the designed asphalt content of the mix, its readings will show lower density for the mix over VRAM, as the extra asphalt content is not accounted for. If a corrected theoretical maximum density (Gmm) that includes the extra asphalt content could be entered into the nuclear gauge, the readings would show higher density (fewer air voids).

For this reason, nuclear gauge testing within one foot of the joint is NOT recommended. The nuclear gauge will not be calibrated to the new theoretical maximum density (Gmm) of the asphalt plant mix with VRAM. To accurately determine air voids, the Gmm of a core containing VRAM must be included in the calculation.

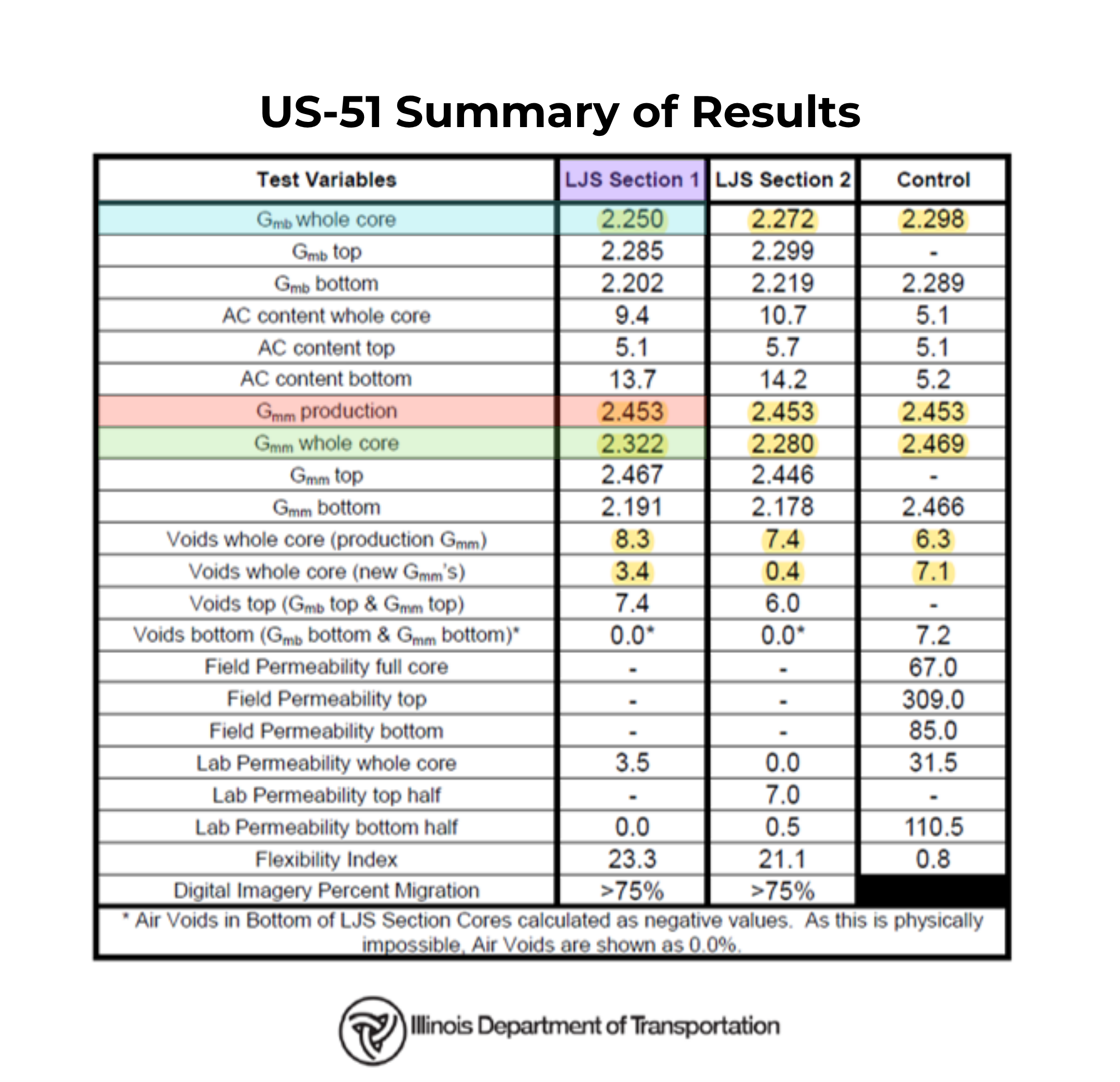

To illustrate these concepts in practice, below are findings from an early IDOT test project.

Example from IDOT – Importance of Calibration

Illinois DOT investigated a 15-year-old project in 2017 to determine properties of cores with and without VRAM. Gmb and Gmm were measured for half-cores and whole cores. Lab permeability was also measured, showing that the VRAM/LJS cores have zero or near zero permeability despite the lower density (Gmb) compared to the control core.

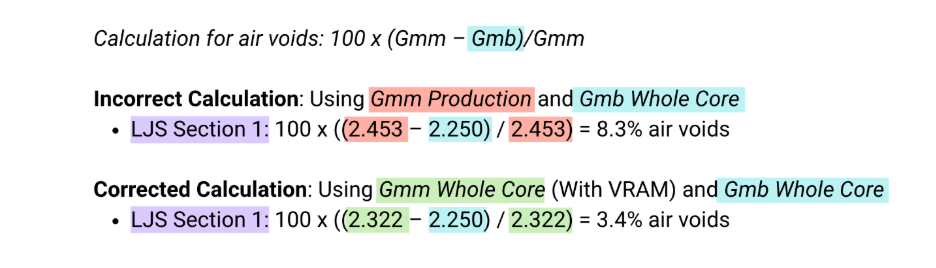

When calculating air voids using a nuclear gauge over VRAM, technicians and engineers often make the mistake of using the wrong theoretical maximum density calibration: the plant produced mix Gmm, instead of the corrected Gmm that factors in VRAM’s asphalt content. In the field, there is no easy way to quickly determine the corrected theoretical max density with VRAM, which is why the density reading may appear to show that higher air voids exist, when in reality, many of those voids have been filled.

To accurately measure the density of a core with VRAM:

- Determine the bulk specific gravity (Gmb) of the core

- Break down the core and measure the theoretical maximum density (Gmm)

- Calculate the % density (or air voids)

Here is this result in action:

IDOT US-51 after 15 years:

Control section VRAM section

These photos show that durability of pavement is more than the data point of density – VRAM/LJS cores have zero or near zero permeability despite the lower density (Gmb) compared to the control core. VRAM strengthened joints last.

VRAM has demonstrated its ability to significantly reduce permeability and extend the life of longitudinal joints, even when traditional density measurements suggest otherwise. Because VRAM fills air voids and increases asphalt content, nuclear density gauge readings near the joint can be misleading. As a result, many agencies—including IDOT—have adopted specifications that waive centerline density testing when VRAM is used. For accurate air void determination, lab testing of cores is essential. Field density testing with nuclear gauges at VRAM-treated joints is not recommended and may misrepresent actual pavement quality.