About this project:

A Void Reducing Asphalt Membrane, (VRAM), project took place on I-57 in Champaign County, Illinois on October 5th. This was a 70,688-foot project, running from 2 miles South of Thomasboro to US-136 in Rantoul. IDOT designated VRAM for the application to the centerline joint. (Note: in Illinois VRAM is often referred to as LJS).

This was an Illinois Department of Transportation (IDOT) project.

The VRAM applicator for this project was Illiana.

The prime paving contractor for this project was United Contractors Midwest (UCM).

The application band width for the VRAM on this project was targeted to be applied to the centerline joint over existing binder at a width of 18”. The binder course started at the US-150 intersection in the northbound lane and continued heading northbound. The HMA paving occurred shortly after the application of the VRAM.

VRAM can help state and local agencies achieve many of the DOT’s Strategic Objectives

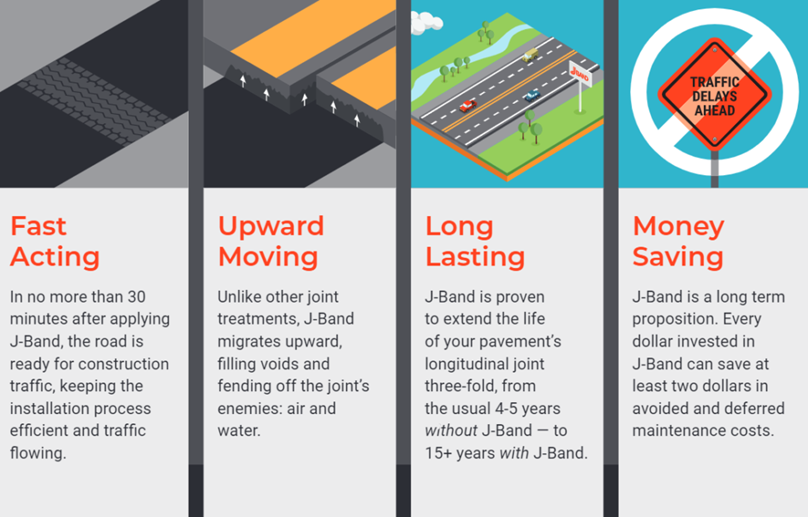

Agencies are now being asked to build more resilient and sustainable transportation systems to benefit and protect communities. VRAM can help achieve these objectives. VRAM can help improve the resilience of at-risk infrastructure by helping build longer-lasting, safer roads. Historical data from previous VRAM projects shows that an investment in protecting the longitudinal joint helps roads last up to 5 years longer and delivers a return on investment of 3 to 5 times its cost.

In other words, if you invest $10M in VRAM, you can save $30M to $50M. An example from Indiana DOT life cycle cost analysis (LCCA) showed that an investment of $12.5M in J-Band® would result in a $39M in savings (approximately 3:1 ROI). Funds invested in J-Band® will save agencies by avoiding and deferring maintenance costs.

J-Band® is a VRAM product of Asphalt Materials, Inc. with a long performance track record dating back to 2002. J-Band was created in the labs of The Heritage Research Group in collaboration with state and local agencies and industry experts.

Applying VRAM to the centerline joint aids in protecting the most permeable part of the road from air and water, which will damage the pavement as they work down into the pavement.

J-Band® is Asphalt Materials’ VRAM and unlike other methods is a materials approach to fixing the age-old problem of longitudinal joint issues. It is a highly polymer-modified asphalt cement that is placed along the location of the longitudinal joint before paving.

To learn more about Asphalt Material’s mix application product line AMIBIND™, visit the website: https://asphalt-materials.com/products/

Editor’s Notes:

Centerline joints and longitudinal joints are often used interchangeably in describing the area of the pavement where two paved sections come together.

VRAM, Void Reducing Asphalt Membrane is referred to in Illinois as LJS, Longitudinal Joint Sealant.

Depending on the situation VRAM can be sprayed at different widths. It should be noted that 18” is a typical application width for centerline applications. Edgeline applications have often been targeted at 9”.

J-Band® is a VRAM product of Asphalt Materials, Inc. that was created in the labs of The Heritage Research Group.

J-Band®, CCAP® and T-Bond® are registered trademarks of Asphalt Materials, Inc.

AMIBIND™, AMIBOND™, AMICYCLE™, AMIGUARD and AMISEAL™ are trademarks of Asphalt Materials, Inc.