About this project:

A Void Reducing Asphalt Membrane, (VRAM), project took place on August 29th and 30th in Lawrence County, Illinois.

This 66,040-foot project took place on IL-33 from the Crawford County line to Old US 50.

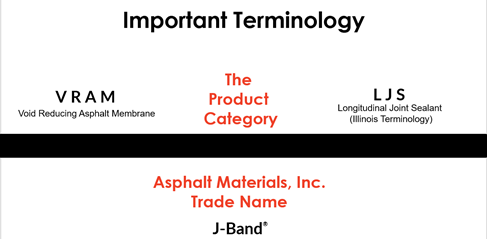

VRAM was designated for application to the centerline joint with a width of an 18”. (Note: in Illinois VRAM is referred to as LJS).

This was an Illinois Department of Transportation (IDOT) project.

The applicator for this project was Road Fabrics Inc (RFI).

The prime paving contractor was Ambraw Asphalt.

The VRAM application began on the 29th of August and continued into the 30th with the paving of the road. The bandwidth for this project was targeted at 18” wide and was applied over a recently milled and untacked surface. The application of the VRAM began in the early morning, beginning at the staging area and continuing northward.

Once the VRAM was placed, the asphalt paving operation began the following day. The paving train consisted of:

- A Roadtec RP 195e paver

- A CAT CB 68B breakdown roller at 12 ton

- A Rosco TruPac 915 pneumatic roller at 15-ton intermediate roller

- A Hamm HD 120i – 12-ton finish roller

Paving began in the northbound lane paving northward at a width of 12 feet. The breakdown roller was making 3 vibratory passes, along with 5 passes with the intermediate roller. The mix was an ILDOT 9.55 coarse graded surface mix, PG64-22, Type C, N70.

VRAM: A Proven Track Record of Protecting Centerline Joints in 23 States

VRAM, a Void Reducing Asphalt Membrane, is able to ensure that the driving public has safer, longer-lasting roads. Experience shows roads treated with VRAM will last 3-5 years longer than those not treated.

Applying VRAM to the centerline joint aids in protecting the most permeable part of the road from air and water, which will damage the pavement as they work down into the pavement.

J-Band® is Asphalt Materials’ VRAM and unlike other methods is a materials approach to fixing the age-old problem of longitudinal joint issues. It is a highly polymer-modified asphalt cement that is placed along the location of the longitudinal joint before paving. Below is a video explaining how J-Band works.

You can also learn more about Asphalt Material’s mix application product line AMIBIND™, by visiting the website: https://asphalt-materials.com/products/

Editor’s Notes: VRAM, Void Reducing Asphalt Membrane, is referred to in Illinois as LJS, Longitudinal Joint Sealant.

Centerline joints and longitudinal joints are often used interchangeably in describing the area of the pavement where two sections come together.

Depending on the situation VRAM can be sprayed at different widths. It should be noted that 18” is a typical application width for centerline applications.

J-Band® is a VRAM product of Asphalt Materials, Inc. that was created in the labs of The Heritage Research Group.

J-Band® and CCAP ® are registered trademarks of Asphalt Materials, Inc. AMIBIND™, AMIBOND™, AMICYCLE™, AMIGUARD™, AMISEAL™ are trademarks of Asphalt Materials, Inc.