About this project:

A Void Reducing Asphalt Membrane, VRAM, project took place on Keebler Road in Madison County, Illinois on November 2nd.

This was an Illinois Department of Transportation (IDOT) project.

The span of this project was 3,880-feet long, running from 0.1 miles south of IL-162 to Lorry Lane in Maryville. The application was scheduled to be 18” wide for the 1.5” 9.5mm surface. This was applied over a recently laid binder lift. (Note: in Illinois VRAM is often referred to as LJS).

The VRAM applicator for this project was Road Fabrics Inc (RFI).

The prime paving contractor for this project was Killian.

The project began in the early morning of November 2nd. The distributor was shooting from the driver’s side, beginning at the south end of the project working northbound. Paving of the road followed the completion of the VRAM application later the same day.

Asphalt Paving Operation

The paving process began in the afternoon of November 2nd. The paving began in the northbound lane paving northward. The width for the asphalt paving was targeted at 12 feet. The paving equipment utilized for this project consisted of:

- A CAT 1000E paver

- 2 Sakai SW850ND 12-ton rollers

- A CAT CB54 – 12-ton finish roller

Of the 2 Sakai 12-ton rollers, 1 was utilized as the breakdown roller, and the other as the intermediate roller. The breakdown rollers were making 5 vibratory passes, along with 5 passes with the intermediate rollers.

The project ended midafternoon and came to a successful finish.

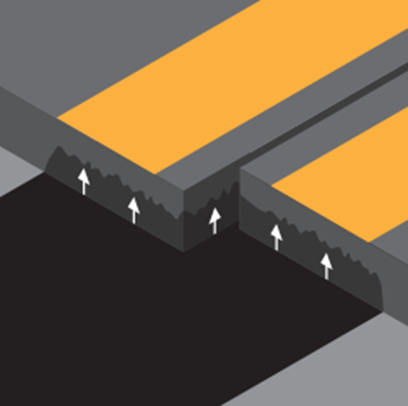

VRAM is a Materials Approach to Solve Joint Issues

When VRAM is applied at the time of construction under the surface, it will reduce the permeability in this critical area of the road. Once the placement of the hot mix asphalt is complete, heat causes the VRAM to physically work its way upwards filling air voids which will reduce permeability.

J-Band®, Asphalt Material’s VRAM product has a performance track record, dating back to 2002. J-Band was created in the labs of The Heritage Research Group in collaboration with state and local agencies and industry experts. One of the primary reasons J-Band is used is economics. When roads last longer, infrastructure dollars go further. How much further?

An Indiana DOT life cycle analysis (LCCA) showed that an investment of $12.5M in J-Band would result in a $39M in savings (approximately 3:1 ROI).

Learn more about how longer-lasting roads save time, money, and lives by reading several studies about VRAM that we have posted on our website. You can access them by clicking this link: https://thejointsolution.com/resource/studies/

Editor’s Notes:

Centerline joints and longitudinal joints are often used interchangeably in describing the area of the pavement where two paved sections come together.

VRAM, Void Reducing Asphalt Membrane is referred to in Illinois as LJS, Longitudinal Joint Sealant.

Depending on the situation VRAM can be sprayed at different widths. It should be noted that 18” is a typical application width for centerline applications.

J-Band® is a VRAM product of Asphalt Materials, Inc. that was created in the labs of The Heritage Research Group.

J-Band®, CCAP® and T-Bond® are registered trademarks of Asphalt Materials, Inc.

AMIBIND™, AMIBOND™, AMICYCLE™, AMIGUARD™ and AMISEAL™ are trademarks of Asphalt Materials, Inc.