About this project:

A VRAM project on I-24 in Massac County, Illinois took place on August 19th. This 161,778-foot project went from the Johnson County line to the Ohio River Bridge. IDOT designated VRAM for the application to the centerline joint prior to the final HMA paving.

This was an Illinois Department of Transportation (IDOT) project.

The VRAM applicator for this project was Illiana.

The prime paving contractor for this project was ET Simonds.

The application band width for the VRAM on this project was targeted to be 18” wide and applied to the centerline joint prior to paving. The VRAM for this project was applied over a recently tacked and milled surface course in the driving lane, and recently applied level binder in the passing lane.

The VRAM application began in the early morning, applying the product going southbound from the driver’s side. The paving occurred shortly after the application of the Void Reducing Asphalt Membrane. (Note: In Illinois VRAM is referred to as Longitudinal Joint Sealant or LJS).

Asphalt Paving Operation

The paving took place later this day. The paving equipment used consisted of a Roadtec SB2500B MTV, a Vogele Super 2000-3 paver, a Hamm HD-120i – 12-ton breakdown roller, a Sakai R2H and a Alitec AER315 3 wheeled rollers (both at 12 ton working in tandem), and a Hamm HD-120i– 12-ton finish roller. The breakdown roller was making 3 vibratory passes, along with 5 passes with the intermediate rollers.

The paving began in the southbound driving lane paving southward. The paving was about 12 feet wide. This project came to a successful close later this day.

VRAM is a Materials Approach to Solve Joint Issues

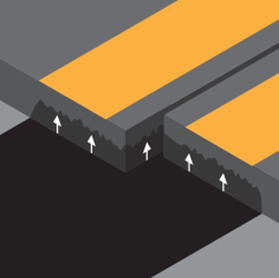

When VRAM is applied at the time of construction under the hot mix asphalt (HMA), it will reduce the permeability in this critical area of the road. Once the placement of the HMA is complete, the heat will cause the VRAM to physically migrate upwards, resulting in the filling of voids which will reduce permeability.

An illustration of the VRAM material migrating upwards once the hot mix asphalt is put down. This action results in the filling of voids with asphalt material from the bottom-up.

States Continue to Find Success with VRAM

The Wisconsin Highway Research Program/Department of Transportation conducted a study on Void Reducing Asphalt Membrane (VRAM) to identify the benefits of including this step in the paving process.

Based on published data and review of case studies, implementing Void Reducing Asphalt Membrane (VRAM) during the construction process is recommended. Post-construction, it is recommended to use penetrating asphalt emulsions as a preventative and remedial treatment for longitudinal joints.1

To read about other VRAM studies you can follow this link. https://thejointsolution.com/resource/studies/

SOURCES:

1 https://wisconsindot.gov/documents2/research/0092-21-05-research-brief.pdf

Editor’s Notes:

Centerline joints and longitudinal joints are often used interchangeably in describing the area of the pavement where two paved sections come together.

VRAM, Void Reducing Asphalt Membrane is referred to in Illinois as LJS, Longitudinal Joint Sealant.

Depending on the situation VRAM can be sprayed at different widths. It should be noted that 18” is a typical application width for centerline applications. It has also been used successfully on edgeline applications.

J-Band® is a VRAM product of Asphalt Materials, Inc. that was created in the labs of The Heritage Research Group.

J-Band®, CCAP® and T-Bond® are registered trademarks of Asphalt Materials, Inc.

AMIBIND™, AMIBOND™, AMICYCLE™, AMIGUARD™ and AMISEAL™ are trademarks of Asphalt Materials, Inc.