Road managers know that the longitudinal joint is the first part of the pavement to fail. As a road’s most permeable part, this joint is susceptible to the elements. Air and water work down through this gap causing the joint to deteriorate, crack and pothole. And when the longitudinal joint fails, the rest of the road soon follows—triggering the need for even more maintenance.

About this project:

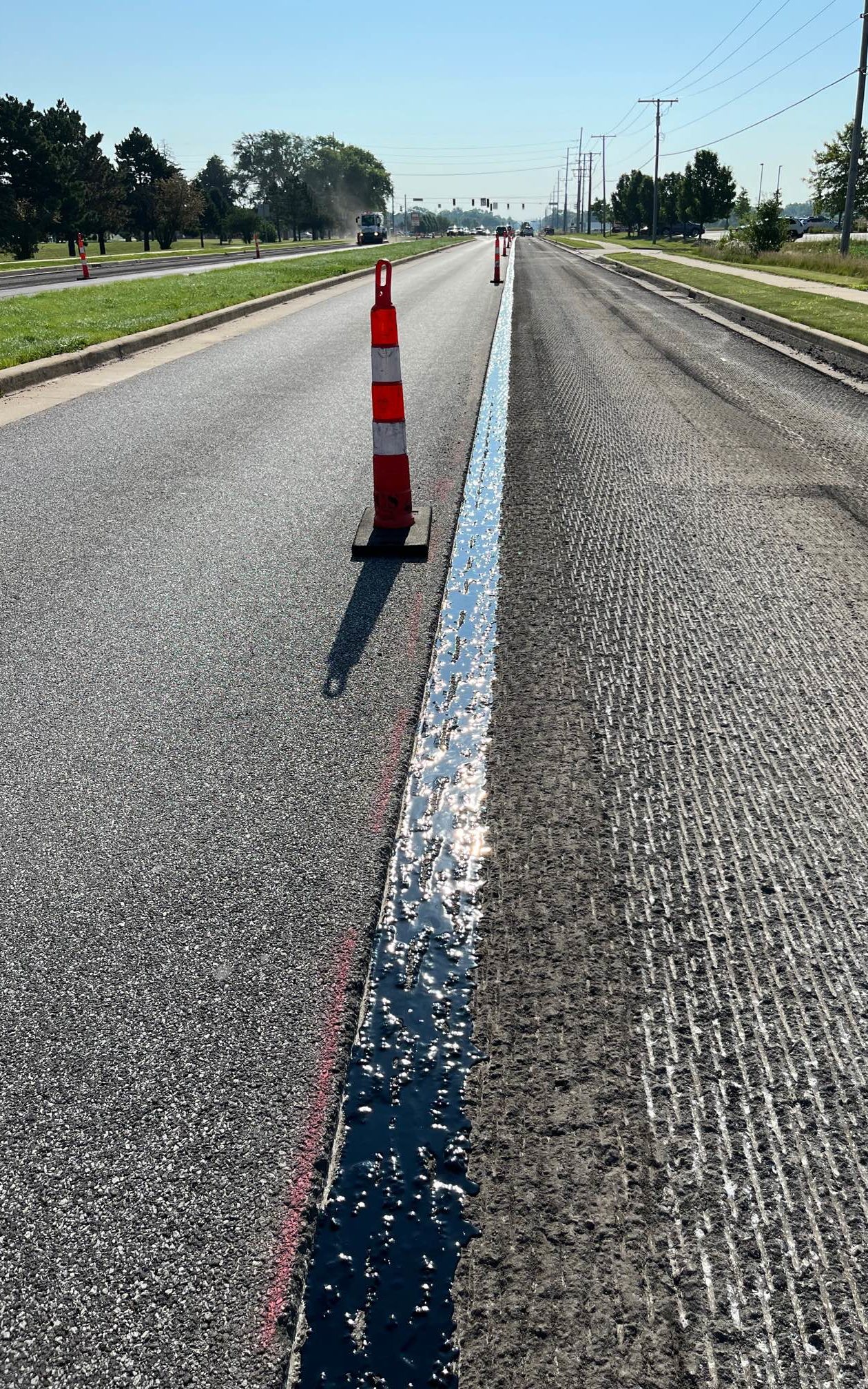

An InDOT project using VRAM took place on US-6 in Porter County, IN on July 21st. VRAM is a Void Reducing Asphalt Membrane.

The project was on US-6 from State Road 149 west to Scottsdale Street in Portage. This is a four-lane road with a middle turn lane that has multiple side streets, businesses, and Portage High School, all located in the project work area. InDOT had designated VRAM for application to the centerline joint prior to the final HMA paving.

The VRAM applicator for this project was Illiana.

The prime paving contractor for this project was Milestone.

The application band width for VRAM on this project was targeted at 18” wide. Milestone took care of creating a clean and dry milled surface for the VRAM to be laid over. Illiana, the applicator for this project, applied VRAM as shown in the pictures above. Paving occurred shortly after the application of the VRAM.

VRAM Can Help State & Local Agencies Achieve Strategic Objectives.

Agencies are now being asked to build more resilient and sustainable infrastructure to benefit and protect communities, and VRAM can help achieve these objectives. VRAM can help improve the resilience of at-risk infrastructure by helping build longer-lasting, safer roads. Historical data from previous VRAM projects shows that an investment in protecting the longitudinal joint helps roads last up to 5 years longer and delivers a return on investment of 3 to 5 times its cost.

J-Band®, Asphalt Material’s, Inc. VRAM product has a performance track record dating back to 2002. J-Band was created in the labs of The Heritage Research Group in collaboration with state and local agencies and industry experts. In fact, an Indiana DOT life cycle analysis (LCCA) showed that an investment of $12.5M in J-Band would result in a $39M in savings (approximately 3:1 ROI). Every dollar invested in J-Band® can save at least two dollars in avoided and deferred maintenance costs, because roads last longer.

VRAM creates longer-lasting, safer roads which leads to a more resilient, reliable and sustainable infrastructure. And when roads last longer, infrastructure dollars go further.

Learn more about how longer-lasting roads save time, money, and lives by reading the several studies about VRAM that we have posted on our website. You can access them by clicking this link: https://thejointsolution.com/resource/studies/

Editor’s Notes:

Centerline joints and longitudinal joints are often used interchangeably in describing the area of the pavement where two paved sections come together.

VRAM, Void Reducing Asphalt Membrane is referred to in Illinois as LJS, Longitudinal Joint Sealant.

Depending on the situation VRAM can be sprayed at different widths. It should be noted that 18” is a typical application width for centerline applications.

J-Band® is a VRAM product of Asphalt Materials, Inc. that was created in the labs of The Heritage Research Group.

J-Band®, CCAP® and T-Bond® are registered trademarks of Asphalt Materials, Inc.

AMIBIND™, AMIBOND™, AMICYCLE™, AMIGUARD and AMISEAL™ are trademarks of Asphalt Materials, Inc.