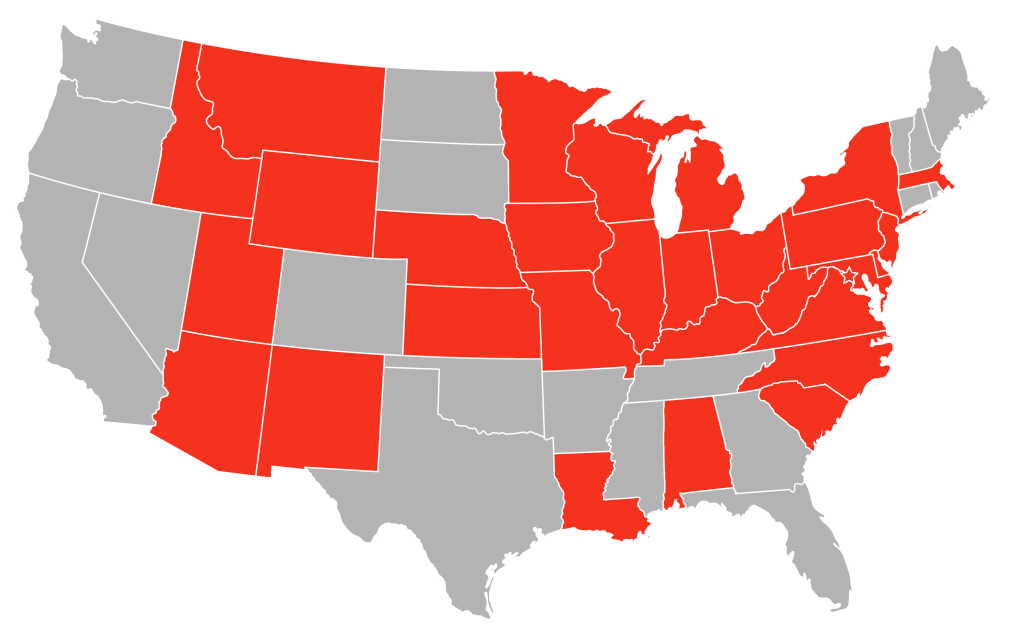

In October of 2025, the Louisiana Department of Transportation and Development (LaDOTD) launched its first J-Band® Void Reducing Asphalt Membrane (VRAM) project, marking Louisiana as the 29th state to use this innovative technology to extend the life of longitudinal asphalt construction joints.

Why is VRAM Adoption Spreading So Quickly?

Since its debut in 2002, VRAM has been strengthening longitudinal joints across the country. After early success in Illinois was published nationally, interest surged. Engineers nationwide began using VRAM to extend joint life by 3–5 years and reduce maintenance costs.

So, what is VRAM? It’s a highly polymer-modified asphalt product applied at joint areas before surface paving. By filling air voids, VRAM prevents water and air infiltration—two major causes of joint deterioration.

LaDOTD’s Test Project Details

- Prime Contractor: RJ Daigle

- VRAM Applicator: Evergreen Roadworks™

- Location: Baton Rouge, LA

- Scope: Wax Road (LA 3034)

- VRAM on 2.2 miles, from Sullivan Road to LA 37

- Date: October 7, 2025

Wax Road runs through both commercial and suburban areas, with lane counts ranging from two to five. Some sections required full-depth rehabilitation, including 12 inches of cement-treated subgrade and 12 inches of stabilized base course. Simpler sections were milled 4 inches deep before new asphalt binder and wearing courses were applied.

Given the investment in Wax Road’s reconstruction, LaDOTD chose to enhance a portion of the wearing course with VRAM to reduce future joint maintenance.

After paving the binder course, Evergreen Roadworks applied an 18-inch-wide band of VRAM along the centerline joints using a specialized distributor truck. Thanks to its unique formula, the VRAM remained in place after the hot application. For added protection in case of rain, sand was optionally placed on the band by hand. Within 10–15 minutes, the material cooled and became non-tracking. The application started at 9 a.m. and finished by 2:30 p.m.

The next morning, RJ Daigle paved the surface course over the intact VRAM. As the asphalt was compacted, VRAM melted and migrated upward into the voids, creating a sealed, impermeable structure from the bottom up—unlike topical joint sealants.

VRAM is applied on the binder course in an 18” wide band of material using a specialized distributor truck with a parallel spray bar. Photos courtesy of Associated Asphalt - An Ergon Company.

Hot mix asphalt is paved over the VRAM band so the material can migrate up into the joint area and fill air voids in this lower-density part of the mat. Photos courtesy of Associated Asphalt - An Ergon Company.

What This Means for Louisiana and Beyond

Every new state that begins using VRAM contributes to longer-lasting roads across America. Early adopters like Illinois, Indiana, and Ohio have reported significant cost savings—up to 3–5x return on investment—thanks to reduced joint maintenance.

J-Band® VRAM isn’t just innovative; it’s a proven solution to one of pavement’s most persistent problems.