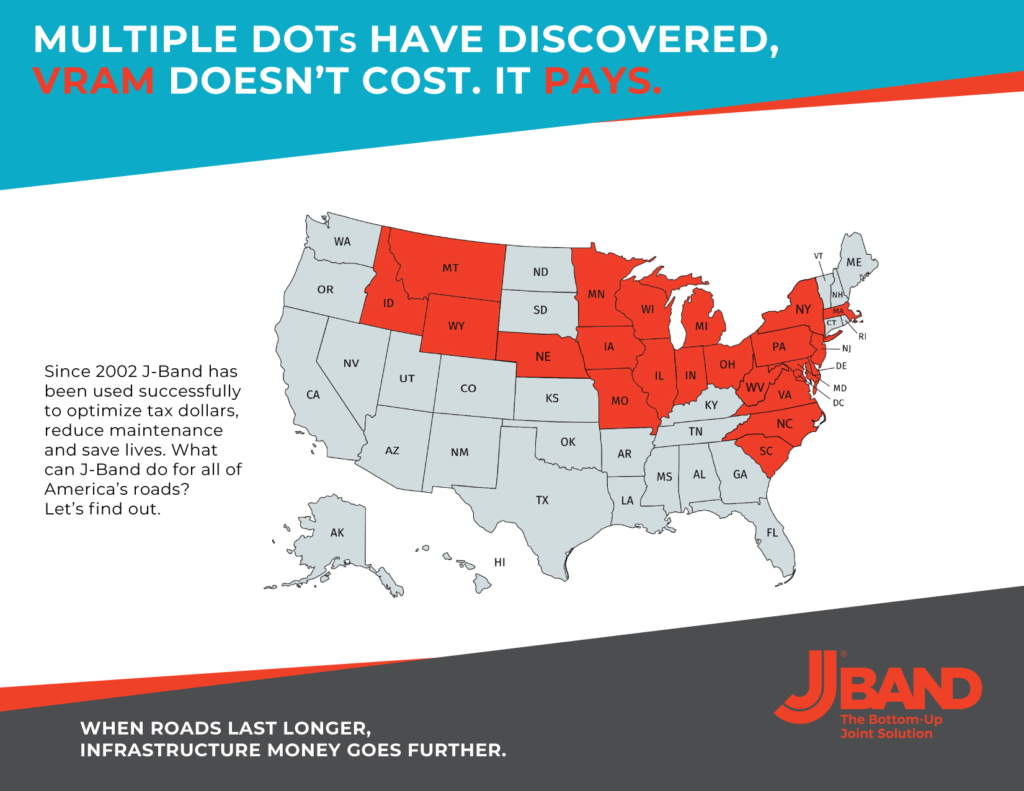

This week, Sutton, Nebraska began their first application of J-Band, a Void Reducing Asphalt Membrane also known as VRAM. This makes Nebraska the 22nd state to use VRAM to help protect the center of the road.

Why is it important to protect the centerline?

Longitudinal joints(1) are often the first place a pavement begins to fail. With their inherently lower density, longitudinal joints fail by cracking, raveling and potholing because of the intrusion of air and water. Investing in ways to create longer-lasting roads becomes even more urgent when we know that longitudinal joints are vulnerable. VRAM is a proven, materials approach, that continues to prove successful throughout the U.S.

Where it all began.

Many states were looking for methods to improve joint performance of their asphalt pavements due to their longitudinal joint issues. After trying several less-than-successful traditional solutions to seal air voids along the longitudinal joint, the Illinois Department of Transportation (IDOT) partnered with the Heritage Research Group from Indianapolis. They wanted to develop a method that would seal the joint from the bottom up.(2) J-Band isn’t a new, unproven technology and product on the market either. Since 2002, J-Band has been used on roadways to support and protect the centerline.

How VRAM Works?

Prior to paving VRAM is sprayed on an 18” wide location directly under the area where the longitudinal joint will be. When the HMA is placed and compacted over VRAM, the material migrates upward into the fresh pavement. It fills voids to help ensure the joint is less permeable.

An American Innovation

VRAM has been shown to be a proven solution to the longitudinal joint problem. J-Band® is an American–Made VRAM, that is applied during the road construction process just below the joint.

We’d like to thank the Nebraska Department of Roads for their hard work and collaboration in helping to accelerate the adoption of innovation and technologies like VRAM.

Asphalt Materials, a midwestern-based company that has been involved in the asphalt business since 1956, supplies this industry-leading VRAM named J-Band®.

J-Band® is a product of Asphalt Materials, Inc. and was created in the labs of Heritage Research Group. To learn more about J-Band, or to connect with our team, you can email us at: Marketing@Asphalt-Materials.com.

Notes:

- The density and air void content of asphalt mixtures affect the durability and performance of asphalt pavements. Pavement longitudinal joints typically have a lower density than the mat because they receive less compaction than the center section of the mat for various reasons. The higher air void percentages resulting from lower densities can lead to high permeability and allow water infiltration, which in turn can cause moisture-induced damage and decrease base and subbase support to the pavement, reducing pavement life.

- Void-reducing asphalt membrane (VRAM) has been used at the longitudinal joints of asphalt pavements to achieve higher densities and prevent moisture infiltration, thereby reducing deterioration at the longitudinal joints. VRAM is applied before the hot-mix asphalt (HMA) layer is placed and migrates into the HMA to fill 50% to 70% of the air voids. (Iowa State University Study for Minnesota Department of Transportation, DEC. 2020)

- TRB paper. https://journals.sagepub.com/doi/10.1177/03611981211044451

- Wisconsin State Study https://wisconsindot.gov/documents2/research/0092-21-05-research-brief.pdf

Editor’s Notes:

Void Reducing Asphalt Membrane or VRAM is referred to in Illinois as Longitudinal Joint Sealant or LJS.

Depending on the situation VRAM can be sprayed at different width’s. This article notes 18” which is a typical application width for centerline applications.

VRAM is a highly polymer-modified asphalt cement that is placed at the location of a longitudinal joint before paving. As HMA is paved over it, the VRAM melts and migrates up into voids in the low-density mix, making the mix impermeable to moisture while sealing the longitudinal joint itself.

The longitudinal joint is the middle of the road, or the seam where the two sides of the pavement come together and is also referred to as the centerline joint.