The most vulnerable part of any new asphalt pavement is typically the longitudinal construction joint. Achieving adequate density at the intersection of pavement lanes is notoriously more difficult than elsewhere on the mat. Lower density translates to more air voids, allowing water and air intrusion to prematurely degrade the pavement.

As a quick and cost-effective solution to longitudinal joint density issues, a material treatment, a void reducing asphalt membrane (VRAM), has been used in over 27 states since 2002. Applied just prior to paving, VRAM works by filling air voids at the longitudinal joint from the bottom up.

For roads with a VRAM, if the joint is compacted with the same requirements as the rest of the mat, agencies do not need to test for density at the joint because the VRAM ensures the joint will at least reach the same performance as the rest of the pavement. Learn more about density requirements here.

J-Band® is the premier VRAM product. The team behind J-Band offers field support to projects implementing the VRAM and regularly reviews past projects, such as the one below, to track their performance.

Project Details

- Owner: Ohio Department of Transportation (ODOT)

- Prime Paving Contractor: Ronyak Paving Inc.

- VRAM Applicator: Specialized Construction Inc. (SCI)

- Location: Burton, Ohio – Geauga County

- Date Constructed: June 1, 2017

- Date Reviewed: November 18, 2024

On a sunny 61°F day, J-Band Field Support Manager Chad Crosby documented the condition of this SR-168 project more than seven years after construction. When paved in 2017, the joint was constructed with a 5.26-mile test section—testing VRAM under the longitudinal joint—and a 1-mile control section.

Project Observations

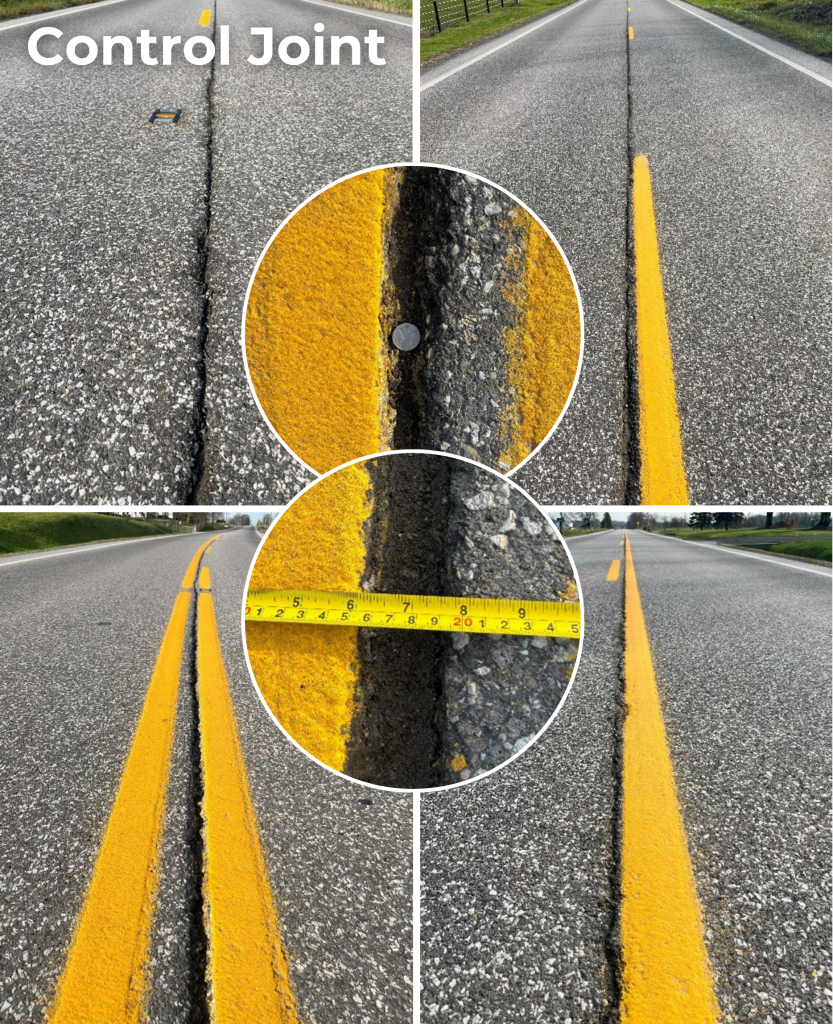

The VRAM test section is significantly outperforming the control section. The control is 100% cracked, with cracks ranging from 1/2”- 3/4” wide, with some stretches of 2” cracks. Meanwhile, the test section experienced small cracks on 75%, with 1/4” maximum width.

| Section | Percent of joint cracked | Width of cracks |

| Control | 100% | ½ " - 2” wide |

| With VRAM | 75% | ¼” wide at most |

Control Section vs VRAM Section Centerline Joint (Quarter for Scale)

With all other variables consistent, the longitudinal joint of the control section vs the joint of the J-Band VRAM section show drastically different levels of deterioration. J-Band has been able to fill the air voids at the joint, protecting it from water permeation that leads to cracking and eventually, potholes.

With J-Band protecting the longitudinal joint, the lifespan of the asphalt overlay can extend an additional 3-5 years beyond the typical 15 years. Due to this deferred and avoided maintenance, agencies can expect at least a $2 return on every $1 invested in J-Band.

To explore the possibilities for your road network, contact our team today!

Editor’s Notes: J-Band® is a registered trademark of Asphalt Materials, Inc. J-Band® was created in the labs of the Heritage Research Group (HRG) and is a product of Asphalt Materials, Inc. (AMI).