VRAM is the materials approach to extend the life of longitudinal joints

Road managers know that the longitudinal joint is the first part of the pavement to fail. As a road’s most permeable part, this joint is susceptible to the elements. Air and water work down through this gap causing the joint to deteriorate, crack and pothole. And when the longitudinal joint fails, the rest of the road soon follows—triggering the need for even more maintenance. The usage of VRAM, a Void Reducing Asphalt Membrane, ultimately reduces the permeability at the longitudinal or centerline joint, the most critical area of the road to protect.

About this project:

On June 8th of this year in Wood County, a 1 ¾” mill and fill project took place on State Road-25. This was a 3.88 mile, five-lane highway that runs through the north end of the business district of Bowling Green, Ohio.

After the VRAM was successfully applied, the paving process was underway. Migration of the VRAM was noted between 5/8” to 3/4”. A faint shadow could be seen on the mat surface right above where the VRAM had been placed. This is the visual confirmation that it had successfully migrated upwards into the mat.

VRAM is a Materials Approach to Solve Joint Issues

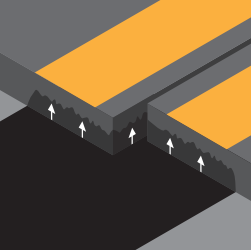

As mentioned above, when VRAM is applied at the time of construction under the surface, it will reduce the permeability in this critical area of the road. Once the placement of the hot mix asphalt is complete, the heat will cause the VRAM to physically migrate upwards, resulting in the filling of voids and reducing permeability.

States Continue to Find Success with VRAM

The Wisconsin Highway Research Program/Department of Transportation conducted a study on Void Reducing Asphalt Membrane (VRAM) to identify the benefits of including this step in the paving process.

Based on published data and review of case studies, implementing Void Reducing Asphalt Membrane (VRAM) during the construction process is recommended. Post-construction, it is recommended to use penetrating asphalt emulsions as a preventative and remedial treatment for longitudinal joints.1

To read about other VRAM studies you can follow this link. https://thejointsolution.com/resource/studies/

SOURCES:

1 https://wisconsindot.gov/documents2/research/0092-21-05-research-brief.pdf

Editor’s Notes:

- Centerline joints and longitudinal joints are often used interchangeably in describing the area of the pavement where two sections come together.

- VRAM, Void Reducing Asphalt Membrane is referred to in Illinois as LJS, Longitudinal Joint Sealant.

- Depending on the situation VRAM can be sprayed at different width’s. It should be noted that 18” is a typical application width for centerline applications.

J-Band® is a VRAM product of Asphalt Materials, Inc. and was created in the labs of The Heritage Research Group.