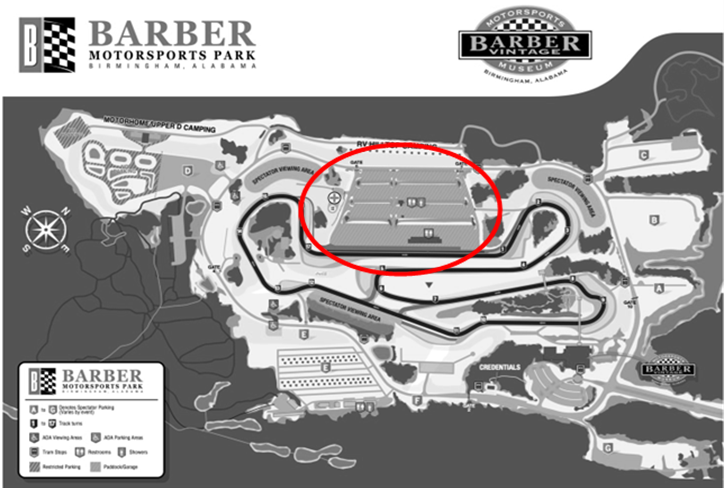

In Birmingham, Alabama, Barber Motorsports Park is a monumental destination for motorsports enthusiasts. The 880-acre park is home to the Barber Vintage Motorsport Museum and multipurpose racing facilities, complete with a track, proving ground and an off-road course.

Year-round, the track hosts events such as the IndyCar Series, Grand-Am, Pirelli World Challenge, the North American Porsche Driving School and many more. On the 14-acre Barber Proving Ground, the new track and wet-dry skidpad are made for debuts, demos and testing, plus driver training and special events. These events include the Porsche Track Experience and Mercedes-Benz Brand Immersion Experience.

The tracks and Proving Ground at Barber Motorsports Park must be carefully built and maintained to handle frequent high-caliber racing. About every 10-12 years, the Proving Ground and Paddock areas are repaved to maintain optimal pavement conditions. For the latest round of maintenance, the park worked with full-service pavement engineering consultants from Advanced Material Services, LLC (AMS).

Specializing in racetracks, automotive proving grounds and research, AMS consultants worked with material supplier Associated Asphalt (AA) — an Ergon company — to implement a unique asphalt technology for the first time at Barber Motorsports Park. As emphasized by AA’s Robbie Robinson, “Investment in [a VRAM] is critical for the longevity of the pavement”.

Project Details

- Owner: Barber Motorsports Park

- Prime Paving Contractor: APAC

- VRAM Applicator: American Paving Fabrics

- Location: Barber Motorsports Park Proving Ground in Birmingham, Alabama

- Date Constructed: July 8-9, 2024

The Construction Process

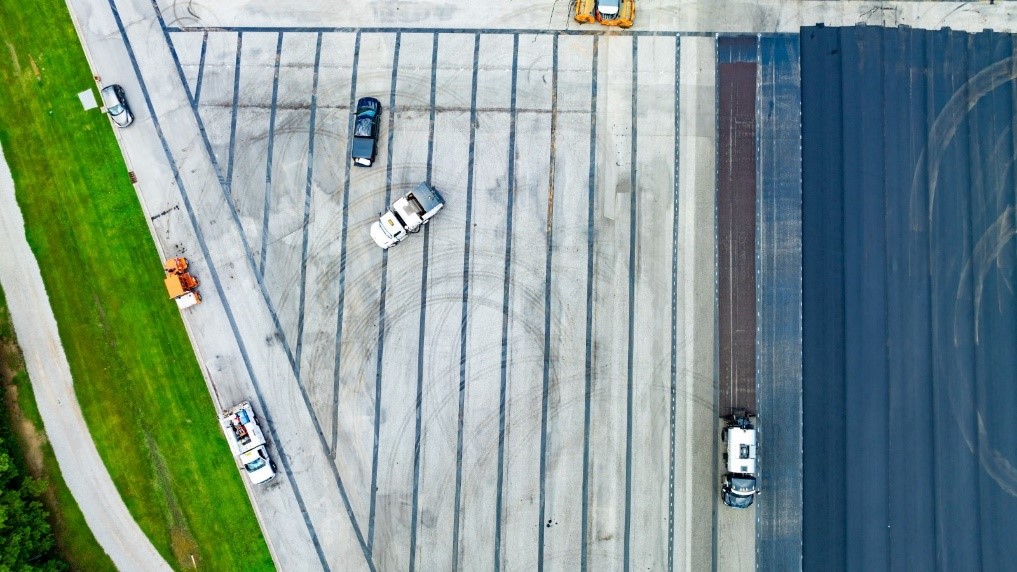

On the Barber Motorsports Park Proving Ground Paddock, American Paving Fabrics applied a void reducing asphalt membrane (VRAM). The application took place just prior to paving at the location where each longitudinal joint of the surface course would be placed.

In total, about 5,000 gallons of VRAM were applied over 40,000 linear feet. The VRAM was sprayed by an asphalt distributor in 18-inch-wide bands and was ready for construction traffic no more than 30 minutes later. The Proving Ground was then tacked and ready for paving.

What is a VRAM?

A VRAM is a unique joint treatment that migrates upward into the pavement, filling voids to fend off air and water that cause joint deterioration.

By applying a VRAM below the joint, pavement permeability above the VRAM area reaches zero or near zero. Reduced permeability translates to durable pavement performance. Across the country, the VRAM, J-Band®, has been shown to extend the life of joints three-fold.

Lab tests also support that longitudinal joints with J-Band have significantly better cracking resistance than joints without J-Band.

20 Years of Racing History with VRAM

Barber Motorsports Park is not the only legendary track enhanced by J-Band. In 2004, the Indianapolis Motor Speedway was repaved using the VRAM. Before this upgrade, the track required resurfacing every 8 to 9 years. However, with the VRAM protecting the pavement joints and Asphalt Materials Inc.’s Rapid Penetrating Emulsion (RPE) sealing the surface, the Speedway has held strong for two decades of intense racing, as of the 2024 Indy 500. That’s 20 years of performance, powered by J-Band.

High-Value Paving Applications

Typically, a Department of Transportation or local agency will apply a VRAM under the full length of a centerline, lane and/or edge longitudinal joint. A VRAM is also used to preserve rumble strips on high-traffic roadways.

The application at the Proving Ground is more akin to a high-value parking lot or high-value transit bay. Down time for any of these lots is detrimental. Use of a VRAM helps avoid excess down time. By extending the life of the most vulnerable part of the pavement, maintenance and repairs can be significantly delayed or eliminated, keeping pavement structures intact for longer.

A VRAM is a long-term proposition. On average, every dollar invested in a VRAM saves project owners a minimum of two dollars from avoided and deferred maintenance costs, saving both time and money.

Collaborating on Unique Solutions

Together Ergon’s Associated Asphalt and Advanced Material Services, LLC advocated for the use of Asphalt Materials, Inc.’s VRAM, J-Band®, to preserve the Barber Motorsports Park Proving Ground in a new way. This unique, high-value lot now has impregnable joints that will stand the test of time.

Editor’s Note:

J-Band® is the premier VRAM created by Asphalt Materials, Inc. J-Band® is a registered trademark of Asphalt Materials, Inc.