A common question regarding Void Reducing Asphalt Membrane (VRAM) concerns how construction traffic should navigate the band of material placed at the road's centerline. Is VRAM really non-tracking? People often ask whether VRAM will track or adhere to vehicle tires if it cannot be paved over immediately.

How Quickly VRAM Becomes Traffic‑Safe

VRAM is engineered to withstand crossing by construction traffic without pickup or tracking within 30 minutes after hot application of about 320°F. Although the specification states a 30–minute window, the material typically cools to a temperature of about 130°F within 10–15 minutes, as observed by contractors and our project support team. Extremely hot weather conditions may skew towards the specified time.

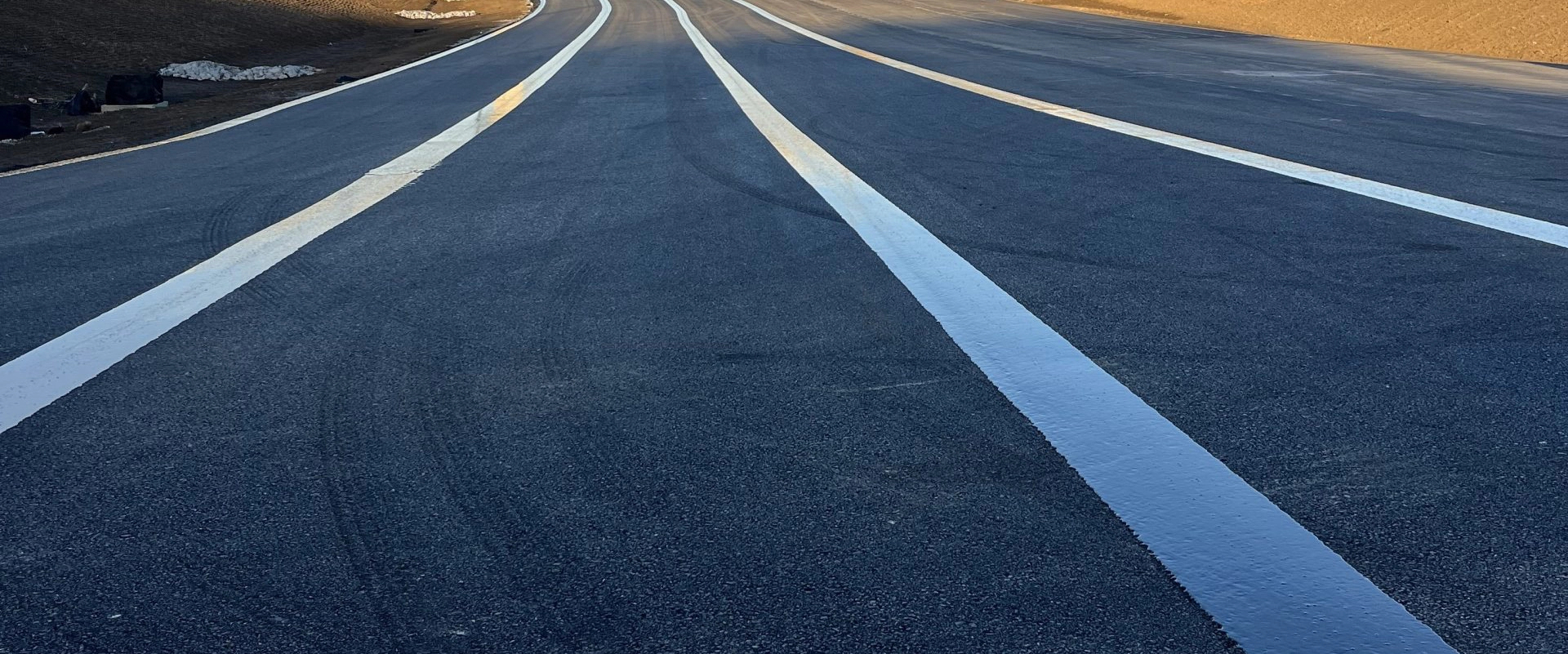

VRAM bands with tire impressions displaying the non-tracking nature of the material

Intact VRAM band visible during HMA paving

Easy Management of VRAM, Even in Hot Weather

In the hottest weeks of summer, a light mist or spray of water can accelerate the cooling of the VRAM band when desired. If construction equipment must drive repeatedly over the material due to the width of the paving section, a controlled system of light water application can also function as an effective bond breaker.

Protecting VRAM When Left Open to Traffic

If rain or dew is expected, and the VRAM band will remain open to traffic, contractors may apply a fine layer of sand immediately after application. The sand provides a frictional surface. When the band must be left open to traffic for multiple days, contractors will sometimes choose to spread sand as a precautionary barrier that helps prevent pickup, especially for public traffic that drives longitudinally on the band. Importantly, the sand does not inhibit VRAM’s upward migration in the asphalt mat.

These bands of VRAM on IL-133 were left open to traffic for two days before paving. The application also extended through an intersection with live traffic. Due to these uncommon circumstances, the VRAM was cooled with water and sanded as a precaution. On this 73°F day, the VRAM was applied at 320°F. It cooled in two minutes to 180°F by the time the sand truck applied sand on the band. This was followed by the water truck, cooling the band to a non-tracking 120°F.

The band remained intact with no pickup through the paving process two days later.

Causes of Material Pickup and How to Avoid Them

VRAM applicators report that pickup is rare. When it does occur, it is usually the result of two conditions:

- Vehicles crossing the VRAM band immediately after application, before cooling to 130°F has occurred.

- Vehicles standing or idling directly on the VRAM band during high heat.

The VRAM Application Checklist includes an important best practice:

“Do not permit public or construction vehicles to stop upon or drive longitudinally directly on top of the VRAM band.”

Bonding Performance on Clean Pavement Surfaces

As long as the pavement is clean and dry, VRAM will bond reliably to the interstitial lift or milled surface. It will remain in position until it is re‑melted by the heat of the surface course placed above it.

Key Takeaways

- VRAM generally cools quickly within 10-30 minutes, allowing construction traffic to cross it without significant delay.

- Pickup is very unlikely when standard application guidelines are followed.

- In hot conditions or situations involving standing traffic, water misting or a light sand cover can be used to ensure VRAM is non-tracking.

Incorporating VRAM into the paving process is both simple and efficient. It is applied immediately before paving as part of the normal construction process and is traffic‑ready after quickly cooling, allowing crews to maintain schedules without added complexity or delay. In fact, by adding VRAM below the surface course, VRAM can prevent the need for future maintenance and repairs, saving time by extending pavement life.

Have more questions? Our team is here to answer: jbandinfo@thgrp.com