All road experts know that the first part of the pavement to fail is the longitudinal joint. Elements such as air, water and dust work their way into voids in the pavement, causing deterioration and cracking the pavement. That is why it is important to invest in a safety net, such as a void reducing asphalt membrane (VRAM).

VRAM is applied at the time of construction. When applied, it significantly reduces air voids in the joints from the bottom up. Protecting the most important part of your road Asphalt Materials, Inc’s (AMI) VRAM product, J-Band® has been proven to extend your road’s life by as much as five years.

Note: VRAM is referred to as a longitudinal joint sealant (LJS) in Illinois.

Project Details

- Owner: Illinois Department of Transportation (IDOT)

- Prime Paving Contractor: Ambraw Asphalt Materials

- Applicator: Illiana

- Location: IL-1, Crawford County, Illinois

- Date Constructed: April 4-9, 2024.

VRAM Application

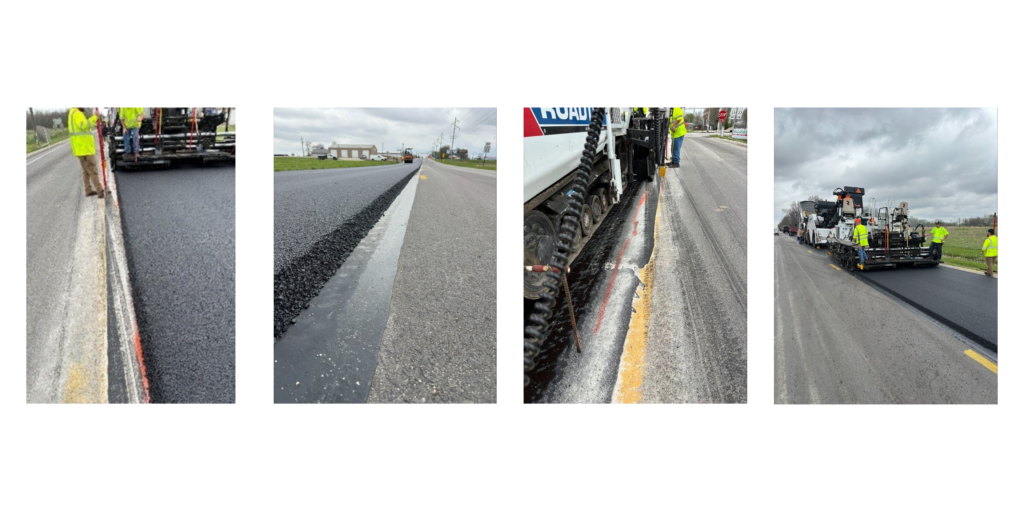

This project took place on IL-1 from IL-33 north to the Clark County line, totaling 11.69 miles in Crawford County. On April 4, VRAM was applied on the centerline joint beginning at IL-33 going north.

The application began around 9:00 a.m. with an ambient temperature of 37F. While the material on board was 330F. The band width on this project was targeted at 18” wide. With paving delayed for three days, Ambraw Asphalt Materials placed sand on top of the VRAM band, after the band cured. A total of 12,430 gallons were applied on April 5, 2024.

Personnel that were present on the job site were crew members from Illiana, crew members from Ambraw Asphalt Materials, Garrett Hixenbaugh from IDOT, Cody Egan and Chad Crosby from AMI.

Paving Observations

Paving began on April 9 around 8:50 a.m. at IL-33 heading north. The ambient temperature for the day was 61F with a surface temperature of 60F.

The equipment used was a RoadTec RP-195e rubber track paver, RoadTec SB3000 shuttle buggy, a Hamm 110i and Hamm 120i steel drum rollers, Hyster C3500 steel drum roller, Volvo DD24 steel drum roller and a Dynapac CS142 3 drum roller.

The mix temperature and migration were recorded throughout, with an average of 265F with a ¼’’ to ½’’ migration rate. The rolling pattern had two breakdown rollers working in a vibratory mode making three full passes. Two secondary breakdown rollers followed the same pattern as the first breakdown rollers with the finish roller working across the mat.

Conclusion

Working together, Illiana, Ambraw Asphalt Materials, IDOT and Asphalt Materials were able to successfully apply VRAM on IL-1 in Crawford County. The use of a VRAM has so many benefits to extend the life of your road.

For a closer look at projects that have incorporated a VRAM during construction and to discover the benefits of longer-lasting roads in terms of cost savings, time efficiency, and safety, you can explore our interactive map here.

Editor’s Notes:

J-Band®, CCAP® and T-Bond® are registered trademarks of Asphalt Materials, Inc. AMIBIND™, AMIBOND™, AMICYCLE™, AMIGUARD™ and AMISEAL™ are trademarks of Asphalt Materials, Inc.