About This VRAM Project

On June 24th, 2022, a Void Reducing Asphalt Membrane (VRAM) project took place in Whitley County on US-30. One lane of the pavement was milled, and then VRAM was applied at the centerline of the road with a 9” band prior to paving the first half of the roadway. The same procedure was completed on the second half of the roadway. For this project, the VRAM applicator was Road Fabrics Inc. (RFI), and the prime paving contractor was Brooks Construction Co.

Brooks had the travel lane and shoulder milled surface cleaned and ready to go for Road Fabrics. The VRAM width at the travel lane shoulder for this project was targeted at 18” wide under where the shoulder joint would be constructed.

Once the VRAM was placed, the paving of the road began. The paving train consisted of a shuttle buggy, paver, and two steel drum rollers. The breakdown rollers were working high to low with 6 passes in vibratory mode, and the finish roller was working in static mode. By the end of the paving process, it was noted that the VRAM had moved up into the new surface, filling voids and a shadow was present on the surface, indicating the success of this project.

Why Do Longitudinal Joints Need Help?

Asphalt pavement density at and near longitudinal construction joints is often significantly lower than density in other areas of the pavement. This can lead to premature deterioration of the longitudinal joint area. Distress associated with longitudinal joints is not confined to a single mix type or geographical area. It is an issue you can find across the country.

Many states have enhanced or created joint performance specifications over the last decade. WisDOT’s WHRP Project 0092-15-09 investigated the influence of construction practice, mix design type, and joint type on the density achieved at the joint location. Since the time of that report, WisDOT has further modified its mixture design and production specification, harmonized joint construction technique among regions, refined the longitudinal joint density specification, and built a more robust data set of paving jobs. (1)

How does VRAM Answer This Problem?

VRAM, a Void Reducing Asphalt Membrane, has been used in 22 states as of July 2022. VRAM is applied to the longitudinal joint of the road to protect the conditions of the road and ensure safer, longer-lasting roads. When there are longer-lasting roads, there is a more resilient and reliable infrastructure and supply chain. And when roads last longer, there is reduced maintenance, which is safer for drivers and construction workers.

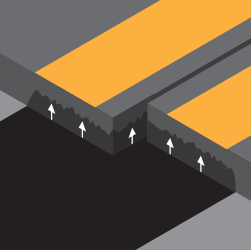

Once the VRAM is placed, it migrates upward into the asphalt mix, filling the voids that would otherwise be penetrated by air and water. This approach helps prevent damage before it begins. With the application of VRAM, roads have been proven to last longer. J-Band®, Asphalt Materials’, VRAM is a breakthrough discovery that helps roads last up to 5 years longer and delivers a return on investment of 3 to 5 times its cost.

To learn more about J-Band®, Asphalt Materials’ VRAM, email: Marketing@Asphalt-Materials.com.

1 – Final Report of Material Specifications for Longitudinal Joint Construction, Remediation and Maintenance1 : https://wisconsindot.gov/Pages/about-wisdot/research/default.aspx

VRAM has been helping roads last longer since 2002 and has been used in 22 States and The District of Columbia. J-Band® is a VRAM product from Asphalt Materials, Inc. that was created in the labs of the Heritage Research Group.

Editor’s Notes: VRAM, Void Reducing Asphalt Membrane, is referred to in Illinois as LJS, Longitudinal Joint Sealant.