About this project:

A Void Reducing Asphalt Membrane, VRAM, project took place on State Road-21 in Tuscarawas County, Ohio on September 17th.

This Project was by the Ohio Department of Transportation (ODOT).

This project covered 1.47 miles on this two-lane highway between Strasburg and Beach City, Ohio. The project started at the intersection of US-250 and terminated at the intersection of SR-21. One of the reasons this project called for the VRAM to be applied across the eventual longitudinal joint is that centerline rumble strips (CLRS) would be installed after the final paving.

The VRAM applicator for this project was Specialized Construction, Inc. (SCI).

The prime paving contractor for this project was North Star.

The target application width of the VRAM for this project was 18” wide. The project began around 9 AM, starting at the intersection with US-250, operating in the southbound lane working northbound.

Paving of the road followed the completion of the VRAM application. The paving process utilized a 424 Fine-Graded mix. The paving began in the southbound lane heading northbound. The paving train consisted of a Cedar Rapids/Terex CR 562 track paver, a Cedar Rapids/Terex transfer machine, and 2 Hypac C784 10 ton steel drum rollers.

The first Hypac steel drum roller was used, as the breakdown operation worked in all vibratory mode. The roller made three passes across the mat for a total of 6 passes, and then another vibratory pass, moving up to his next “rolling pocket”. The second Hypac steel drum roller operator performed all work in static mode. The project ended late morning and was considered a success!

VRAM is a Materials Approach to Solve Joint Issues

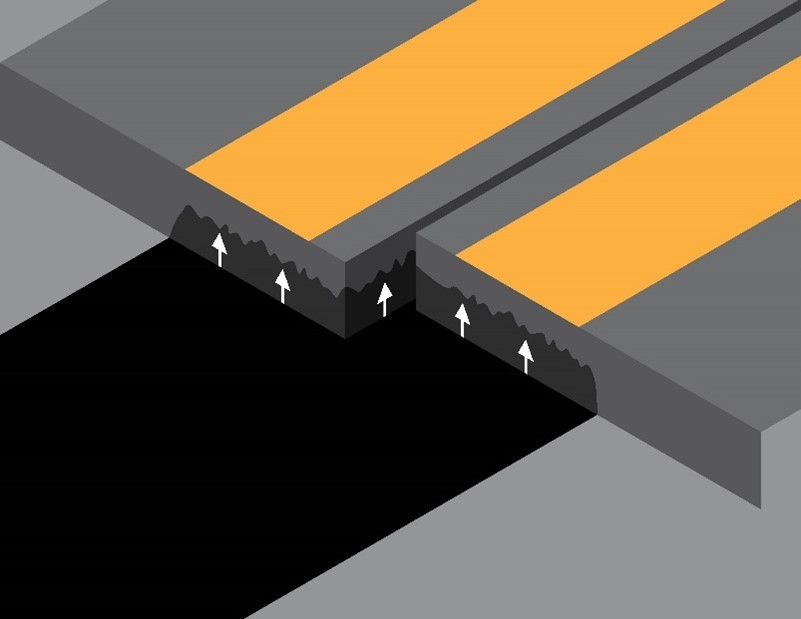

When VRAM is applied at the time of construction under the surface, it will reduce the permeability in this critical area of the road. Once the placement of the hot mix asphalt is complete, heat causes the VRAM to physically work its way upwards filling air voids which will reduce permeability.

J-Band®, Asphalt Material’s VRAM product has a performance track record, dating back to 2002. J-Band was created in the labs of The Heritage Research Group in collaboration with state and local agencies and industry experts. One of the primary reasons J-Band is used is economics. When roads last longer, infrastructure dollars go further. How much further?

An Indiana DOT life cycle analysis (LCCA) showed that an investment of $12.5M in J-Band would result in a $39M in savings (approximately 3:1 ROI).

Learn more about how longer-lasting roads save time, money, and lives by reading the several studies about VRAM that we have posted on our website. You can access them by clicking this link: https://thejointsolution.com/resource/studies/

Editor’s Notes:

Centerline joints and longitudinal joints are often used interchangeably in describing the area of the pavement where two paved sections come together.

VRAM, Void Reducing Asphalt Membrane is referred to in Illinois as LJS, Longitudinal Joint Sealant.

Depending on the situation VRAM can be sprayed at different widths. It should be noted that 18” is a typical application width for centerline applications.

J-Band® is a VRAM product of Asphalt Materials, Inc. that was created in the labs of The Heritage Research Group.

J-Band®, CCAP® and T-Bond® are registered trademarks of Asphalt Materials, Inc.

AMIBIND™, AMIBOND™, AMICYCLE™, AMIGUARD™ and AMISEAL™ are trademarks of Asphalt Materials, Inc.