Why Longitudinal Joint Help is Needed?

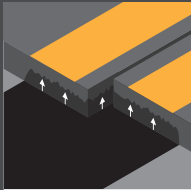

Asphalt pavement density at and near longitudinal construction joints is often significantly lower than density in the mainline areas of the pavement: this can manifest in premature deterioration of the joint area. Distress associated with longitudinal joints is not confined to a single mix type or geographical area. It is an issue you can find across the country. In fact, areas like Washington state and Hawaii have expressed concern about their longitudinal joint issues because of air and water ingress at the longitudinal joint.1

Many states have enhanced or created joint performance specifications over the last decade. WisDOT’s WHRP Project 0092-15-09 investigated the influence of construction practice, mix design type, and joint type on the density achieved at the joint location. Since the time of that report, WisDOT has further modified its mixture design and production specification, harmonized joint construction technique among regions, refined the longitudinal joint density specification, and built a more robust data set of paving jobs. 1

Wisconsin Highway Research Program indicates that joint improvement should focus on reducing permeability of water and air both at and near the joint directly or indirectly. 1

About This Recent Wisconsin Project:

Rock County, WI, underwent its first ever J-Band® project on May 16th, 2022. J-Band is the VRAM product from Asphalt Materials, Inc. The county trunk highway carries the most traffic in Rock County, and this project was a full depth reconstruction (FDR) of the road. The hot mix asphalt (HMA) lay down process consisted of three lifts, two 2.5” binder lifts and a 1.5” surface course, totaling 5.5”.

The final step is the application of J-Band.

The J-Band on this project was placed on May 12th and sat over the weekend with minimal disturbance or loss of material. The following Monday, May 16th, the paving of the upper layer began. During this paving process, there were no issues with carrying on into the J-Band section. Because of the success of placing without cracks, and the “spongy” feeling under boot at the joint, this was the indication that the migration of the J-Band placed had occurred.

Studies Previously Conducted on VRAM in Wisconsin.

The Wisconsin Highway Research Program conducted project 0092-21-05 on April 2022. This study investigates the topic of asphalt pavement density at and near longitudinal construction joints often being significantly lower than density in the mainline areas of the pavement. This can manifest in premature deterioration of the joint area relative to the mainline. Distress associated with longitudinal joints is not confined to a single mix type or geographical area. 1

What is VRAM?

VRAM, a Void Reducing Asphalt Membrane, has been used in 22 states as of June 2022. VRAM is applied to the longitudinal joint of the road to protect the conditions of the road and ensure safer, longer-lasting roads. When there are longer-lasting roads, it leads to a more resilient and reliable infrastructure and supply chain. Once it is placed, the VRAM migrates to the surface, filling the voids that can be penetrated by water and/or air, preventing damage before it may begin. With the application of VRAM, roads have been proven to last over 15 years, compared to roads without VRAM that last around 4 to 5 years.

Results and Recommendations of Research:

Reducing mixture permeability at and near the joint is identified as the most promising method to improve joint performance. The Wisconsin research team recommends that WisDOT continue its current standard practice regarding joint geometry and testing of the joint density, but to also consider the evaluation of other alternatives that show a significant reduction of the risk of premature joint failures. Based on published data and review of case studies, implementing and evaluating Void Reducing Asphalt Membrane (VRAM) during the construction process on a trial basis is recommended.1

1 – Final Report of Material Specifications for Longitudinal Joint Construction, Remediation and Maintenance1 : https://wisconsindot.gov/Pages/about-wisdot/research/default.aspx

J-Band® is a VRAM product from Asphalt Materials, Inc. and was created in the labs of the Heritage Research Group. VRAM has been helping roads last longer since 2002 and has been used in 22 States and The District of Columbia.

Editor’s Notes: VRAM, Void Reducing Asphalt Membrane, is referred to in Illinois as LJS, Longitudinal Joint Sealant.