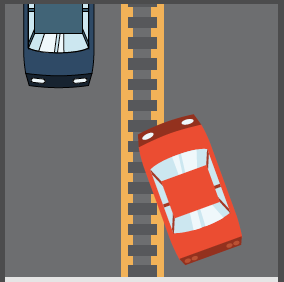

Many states are looking for methods to improve longitudinal joint performance of their asphalt pavements since these joints often fail before the rest of the surface. With their inherently lower density, longitudinal joints fail by cracking, raveling and potholing because of the intrusion of air and water. Due to their longitudinal joint issues,...