Rumble strips are a low-cost measure used to address one of the most serious types of traffic crashes: a lane departure crash. They consist of a set of transverse grooves applied on the shoulder or centerline of a roadway.

In Ohio, Bill OH HB51 is designed to require center-line rumble strips for certain highway projects and was introduced for Ohio’s 133rd General Assembly Session.

OH HB51 Bill Summary

To enact section 5517.06 of the Revised Code to require the Ohio Department of Transportation to install rumble strips along the center line for all two-way, undivided state highways with a speed limit exceeding 45 miles per hour, as a part of specified highway projects.

Expect More Rumble Strips in the Future. For Good Reasons!

Rumble strips provide a tactile and audible warning to alert inattentive (distracted, drowsy, unfocused, etc.) drivers who may unintentionally drift out of their lane. This warning gives the driver an opportunity to correct their action or reduce speed, which may help them avoid or reduce the severity of a crash.

Shoulder rumble strips have been in use all over the country for many years and their safety benefits are well-documented, but centerline rumble strips are relatively new. A three year study in Michigan showed that before-and-after crash study performed for found significant reductions across all crash severities and lane departure crash types, including:

- 50 percent reduction in head-on crashes

- 46 percent reduction in run-off-the-road crashes

- 51 percent reduction in fatal crashes

- 41 percent reduction in incapacitating injury crashes

Rumble strips have become a safety standard on MDOT roadways, and will continue to save lives in the years to come as Michigan moves Towards Zero Deaths.

Department of Transportation’s Focus on Rumble Strips

Early this year, Secretary Buttigieg called the rising traffic deaths a crisis and called for cooperation among all levels of government, industry, and advocacy to change course. What does change course mean? An estimated 20,160 people died in motor vehicle crashes in the first half of 2021, up 18.4% over 2020. That’s the largest number of projected fatalities in that time period since 2006.

“This is a crisis. More than 20,000 people died on U.S. roads in the first six months of 2021, leaving countless loved ones behind. We cannot and should not accept these fatalities as simply a part of everyday life in America,” said United States Transportation Secretary Pete Buttigieg. “Today we are announcing that we will produce the Department’s first ever National Roadway Safety Strategy to identify action steps for everyone working to save lives on the road. No one will accomplish this alone. It will take all levels of government, industries, advocates, engineers, and communities across the country working together.”

“Safer roads and safer speeds are key parts of addressing this crisis of fatalities and serious injuries on our roadways,” said Acting FHWA Administrator Stephanie Pollack. “FHWA is committed to a Safe System Approach and to working closely with local and state transportation agencies to make every road that is designed or built with federal funds safe for everyone who uses it.”

Using Center Line Rumble Strips to Improve Safety

The Department of Transportation’s website recommends the use of rumble strips to improve safety. For nearly ten years, the DOT has acknowledged that installing centerline rumble strips (CLRS) can be an effective, low-cost safety measure for preventing vehicles from crossing the centerline into oncoming traffic. The Kansas State University (KSU) Transportation Center research team has been studying how to get the most from their use.

The results of the before-and-after safety effectiveness study of CLRS in Kansas showed that after CLRS installation on several roads in Kansas, total correctable crashes (those not involving animals, intersections, or due to ice on the pavement) were reduced by 29.21%. Correctable crashes involving fatalities and injuries were reduced by 34.05%. Cross-over crashes were reduced by 67.19%. All of these reductions are statistically significant.

Summary of Centerline Rumble Strips (CLRS) Importance

- Reduces lane departure crashes (i.e., head-on, opposite sideswipe, opposite direction run-off-the-road).

- Reduces fatal and severe injury crashes. Improves safe recovery instances.

- Improves vehicular placement within the lane, which prevents centerline crossovers.

- In inclement weather with poor or limited visibility, assists drivers to maintain proper lane position.

- Assists maintenance trucks (i.e., snowplows, salt trucks) during winter conditions to identify the centerline.

Michigan’s Toward Zero Deaths (TZD) Initiative

The campaign is based on the National Strategy on Highway Safety intended to influence driver behavior and improve safety. With more than 37,000 fatalities occurring on U.S. highways each year, roadway safety remains one of the most challenging issues facing Michigan and the nation. Driver behavior factors into nearly 90 percent of all fatal crashes and one key to changing driver behavior is educating the public on the scope of the issue.

How to use CLRS and Still Build Longer-Lasting Roads

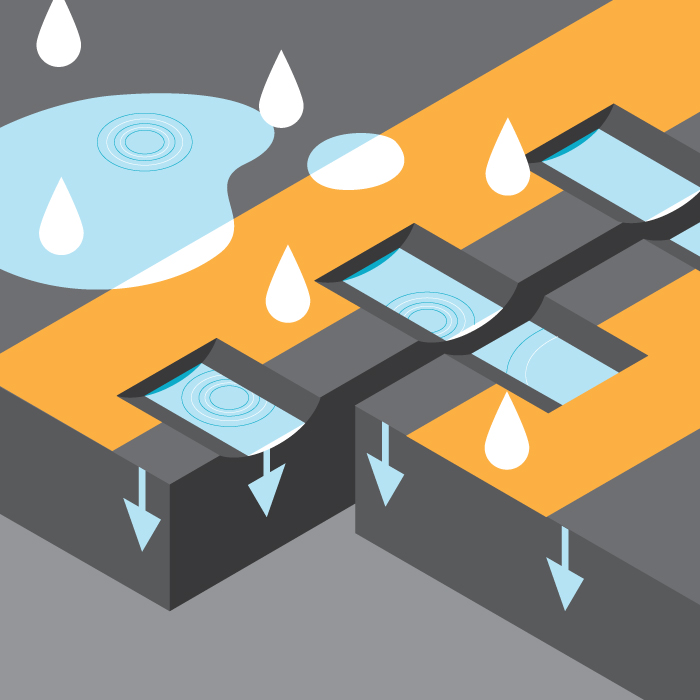

The longitudinal joint is the Achilles’ heel of every paved road. Road managers know the first part of the pavement to fail is the longitudinal joint. As the road’s most permeable part, this joint is susceptible to the elements. Air and water work down through this unavoidable seam in the pavement causing the joint to deteriorate, crack and pothole. And when the longitudinal joint fails, the rest of the road soon follows — triggering the need for even more maintenance.

When CLRS are milled into the center of a road, water collects at the centerline – the most permeable part of the pavement and where rumble strips are installed to improve safety.

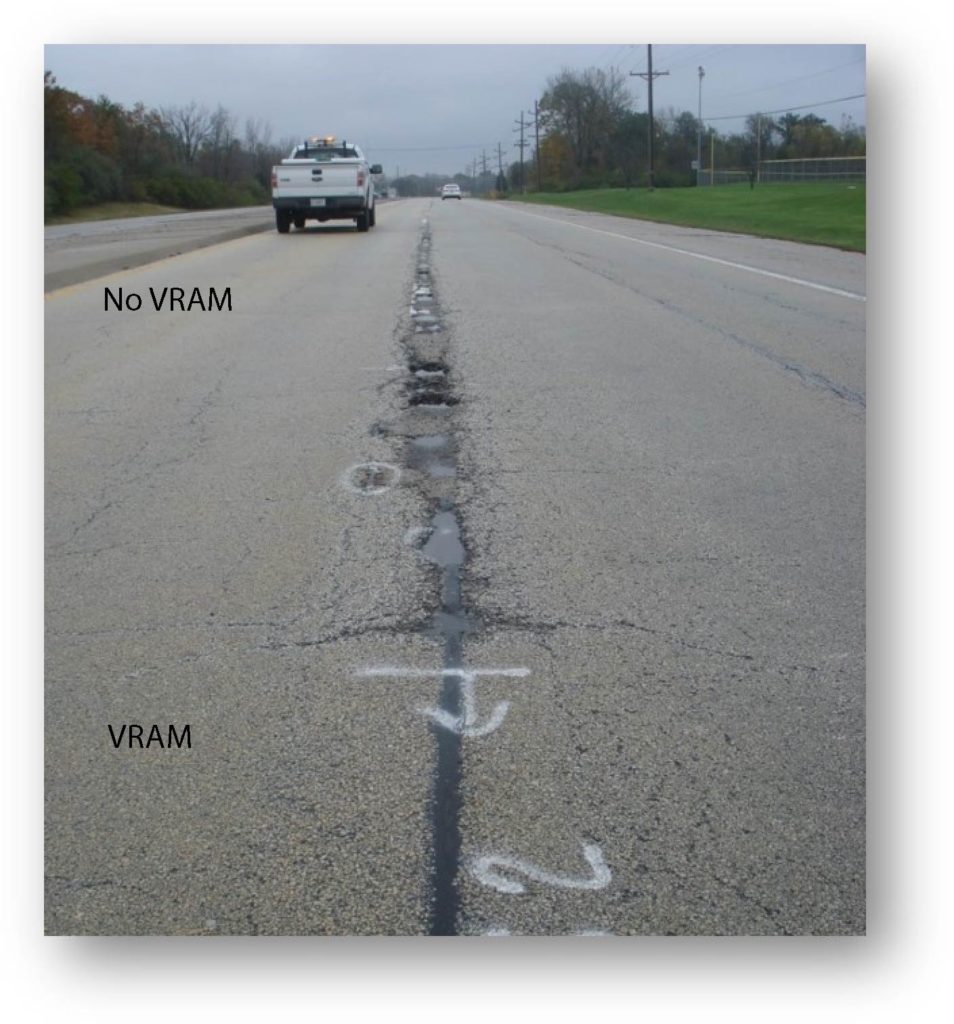

Because we know that the longitudinal joints of roads are already vulnerable, it makes investing in a proven approach to create longer-lasting roads even more critical. VRAM is a proven approach that continues to gain momentum across the U.S.

What is VRAM and How Does it Work?

VRAM is a Void Reducing Asphalt Membrane. Prior to paving, VRAM material is sprayed on an 18” wide location directly under the area where the longitudinal joint will be located. (1) When the HMA is placed and compacted over VRAM, the material migrates upward into the fresh pavement. It fills voids to help ensure the joint is less permeable.

Asphalt Materials, a midwestern based company that has been involved in the asphalt business since 1956, supplies an industry leading VRAM under the brand name J-Band®.

Many believe that J-Band is the American-made solution to the longitudinal joint problem. Developed at the laboratories of Heritage Research Group, J-Band is applied during the road construction process just below the joint. Once covered, it migrates upwards filling the voids that can be penetrated by water and air, preventing damage before it can start.

J-Band isn’t a new trend, although you could say it is trending. It has been used since 2002 on roads in Illinois, J-Band has a proven track record of delivering longer road life and offers an impressive return on investment. An investment in protecting the longitudinal joint helps roads last up to five years longer and delivers a return on investment of three to five times its cost. (2)

J-Band and Centerline Rumble Strips is a partnership in helping create longer-lasting, safer roads that just makes sense. Watch an animated demo of how VRAM works where CLRS are installed by clicking here.

Sources:

- 1 – VRAM is referred to in Illinois as LJS, Longitudinal Joint Sealant. The typical VRAM application for centerline treatments is a width of 18”.

- 2- Transportation Research Board. TRB paper. https://journals.sagepub.com/doi/10.1177/03611981211044451

Other Sources and Notes: - https://www.transportation.gov/briefing-room/usdot-releases-new-data-showing-road-fatalities-spiked-first-half-2021

- https://www.transportation.gov/utc/use-center-line-rumble-strips-improve-safety-two-lane-highways

- https://www.billtrack50.com/BillDetail/1065348

- Michigan DOT: https://www.michigan.gov/mdot/0,4616,7-151-9615_11261-191394–,00.html

- Official Document for Ohio Bill OH HB51. https://www.legislature.ohio.gov/legislation/legislation-summary?id=GA133-HB-51

- The Ohio bill’s sponsors (62) include: Timothy Ginter (R)*, Gil Blair (D), Louis Blessing (R), Kristin Boggs (D), Janine Boyd (D), Juanita Brent (D), Richard Brown (D), Randi Clites (D), Jon Cross (R), Jeffrey Crossman (D), Robert Cupp (R), Bill Dean (R), Sedrick Denson (D), Jay Edwards (R), Haraz Ghanbari (R), Doug Green (R), David Greenspan (R), Stephen Hambley (R), Paula Hicks-Hudson (D), Adam Holmes (R), Stephanie Howse (D), Don Jones (R), Brigid Kelly (D), Laura Lanese (R), George Lang (R), Jeff LaRe (R), David Leland (D), Michele Lepore-Hagan (D), Mary Lightbody (D), P. Scott Lipps (R), Beth Liston (D), Don Manning (R), Gayle Manning (R), Riordan McClain (R), Adam Miller (D), Michael O’Brien (D), Scott Oelslager (R), John Patterson (D), Thomas Patton (R), Rick Perales (R), Phil Plummer (R), Tracy Richardson (R), Craig Riedel (R), Phillip Robinson (D)John Rogers (D), Allison Russo (D), Gary Scherer (R), Michael Sheehy (D), J. Todd Smith , (R), Kent Smith (D), Ryan Smith (R), Lisa Sobecki (D), Dick Stein (R), Reggie Stoltzfus (R), Fred Strahorn (D), Emilia Sykes (D), Nino Vitale (R), Casey Weinstein (D), Thomas West (D), Scott Wiggam (R), Shane Wilkin (R), Paul Zeltwanger (R).