VRAM helps Infrastructure Dollars go Further

A Void Reducing Asphalt Membrane (VRAM) project took place in Adams County, Ohio on June 21st, 2022. The work was done on the two-lane highway State Road 247.

Project Details

VRAM was applied to the centerline of the road, starting just south of SR-32 and continuing south. The prime paving contractor on this project was Brown County Asphalt, and the VRAM Applicator was Specialized Construction, Inc. (SCI), based in Cuyahoga Heights, Ohio. The VRAM band width on this project was targeted at 15” wide.

The paving process followed the application of the VRAM. Once the pavement was put down, a breakdown and finish roller passed over the road in vibratory mode. There was a shadow present of the VRAM, which is visual confirmation that VRAM migrated upward and the job was successful.

What is the Significance of VRAM?

VRAM helps more infrastructure dollars go to new projects and less to maintenance projects. As a road’s most permeable part, the centerline, or longitudinal joint is susceptible to the elements. Air and water work down through this gap causing the joint to deteriorate, crack and pothole. And when the longitudinal joint fails, the rest of the road soon follows—triggering the need for even more maintenance.

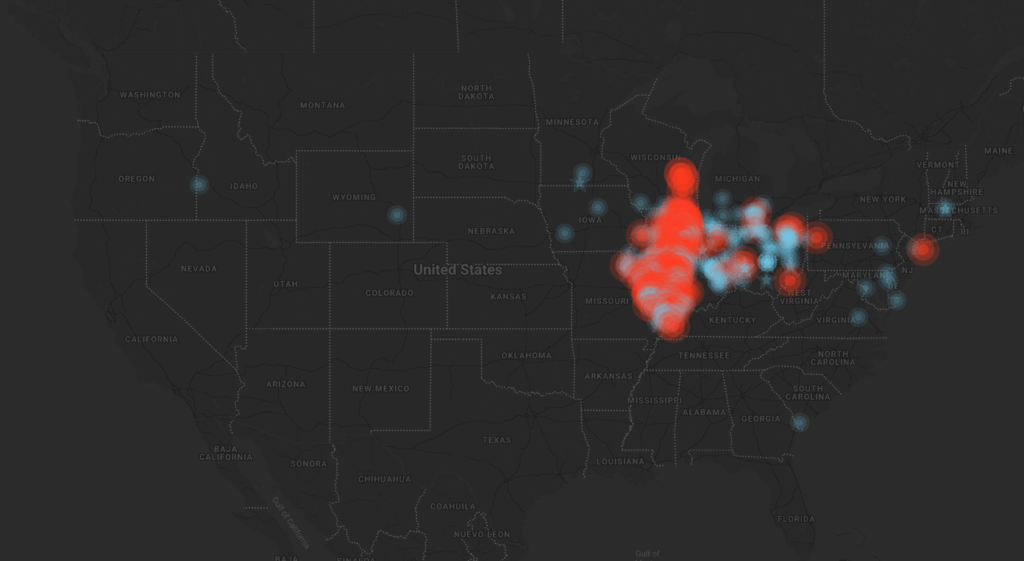

But when maintenance events are delayed and/or avoided, infrastructure dollars go further. Multiple DOTs across 22 states have discovered that VRAM doesn’t cost them. It pays them back. VRAM been used successfully in these states to optimize tax dollars, reduce maintenance and save lives.

VRAM Can Help State & Local Agencies Achieve the DOT’s Strategic Objectives Outlined for FY2022-2026

Agencies are now being asked to build more resilient and sustainable transportation systems to benefit and protect communities, and VRAM can help achieve these objectives. VRAM can help improve the resilience of at-risk infrastructure by helping build longer-lasting, safer roads. Historical data from previous VRAM projects shows that an investment in protecting the longitudinal joint helps roads last up to 5 years longer and delivers a return on investment of 3 to 5 times its cost.

J-Band®, the VRAM product of Asphalt Materials, Inc., has a long performance track record dating back to 2002. J-Band was created in the labs of The Heritage Research Group in collaboration with state and local agencies and industry experts. In fact, an Indiana DOT life cycle analysis showed that an investment of $12.5M in J-Band would result in a $39M in savings (approximately 3:1 ROI). Every dollar invested in J-Band® can save at least two dollars in avoided and deferred maintenance costs.

Others are on the Same Journey

It should also come as a comforting thought that you are following many others that have already begun to experience the benefits of VRAM. We have a number of testimonials from users, in addition to a variety of studies that have been done on or about VRAM. Click here to learn more about these studies.

How Can VRAM See Use in All States, Not Just 22?

An important step in getting more and more states to use and adopt this proven technology is to begin using the product on roads in your state. Get experience with the product, the application and performance. Many states we’ve worked with have created test versus control demonstrations that they continue to evaluate. You can find many of these project case studies on our website. Click here, look for and download VRAM Specifications and J-Band Safety Data.

Another key step in the process is to begin to work with state and local transportation officials to specify VRAM as an approved product. On our website we have a guide to help you write a VRAM specification. We also have a variety of technical and development resources that would enjoy helping you through the process. Contact us at Marketing@Asphalt-Materials.com to start the process!

Editor’s Notes: VRAM, Void Reducing Asphalt Membrane is referred to in Illinois as LJS, Longitudinal Joint Sealant.

Depending on the situation VRAM can be sprayed at different width’s. This article notes 15”, while 18” is a typical application width for centerline applications.

Sources: