As of April 16, 2025, INDOT has released a state design memo specifying the use of Void Reducing Asphalt Membrane (VRAM) for Asphalt Paving in projects with category 2, 3 and 4 surface mixes.

Design Memo No. 25-10: Void Reducing Asphalt Membrane (VRAM) for Asphalt Paving

- To: All Design Personnel and Consultants

- From: Indiana Department of Transportation (INDOT), Kumar Dave - Manager, Pavement Engineering Office, Highway Engineering Division

- Released: April 16, 2025

- Effective: For lettings on or after September 1, 2025

Specifications: This design memo "added Void Reducing Asphalt Membrane (VRAM) requirements on all QC/QA HMA or SMA surface courses. VRAM is required for all 401 QC/QA HMA and 410 QC/QA SMA surface courses over 300 tons, regardless of ESAL category.” Find the complete details here.

Essential Insights

- The INDOT Standards Committee has approved changes to the recurring special provision (RSP) for VRAM under category 2, 3 and 4 surfaces mixes. This RSP will be included as a standard specification in the 2026 INDOT spec book.

- VRAM has already been adopted for category 4 projects (See the May 12, 2023 INDOT Design Memo). This revision adds category 2 and 3.

- J-Band® is the premier VRAM product by Asphalt Materials, Inc. It was created in the labs of Heritage Research Group.

What does this mean for you?

For Agencies

- With a VRAM in place, roads are stronger and last longer, stretching infrastructure dollars further. For every $1 invested in a VRAM, agencies typically save at least $2 in deferred maintenance and repairs.

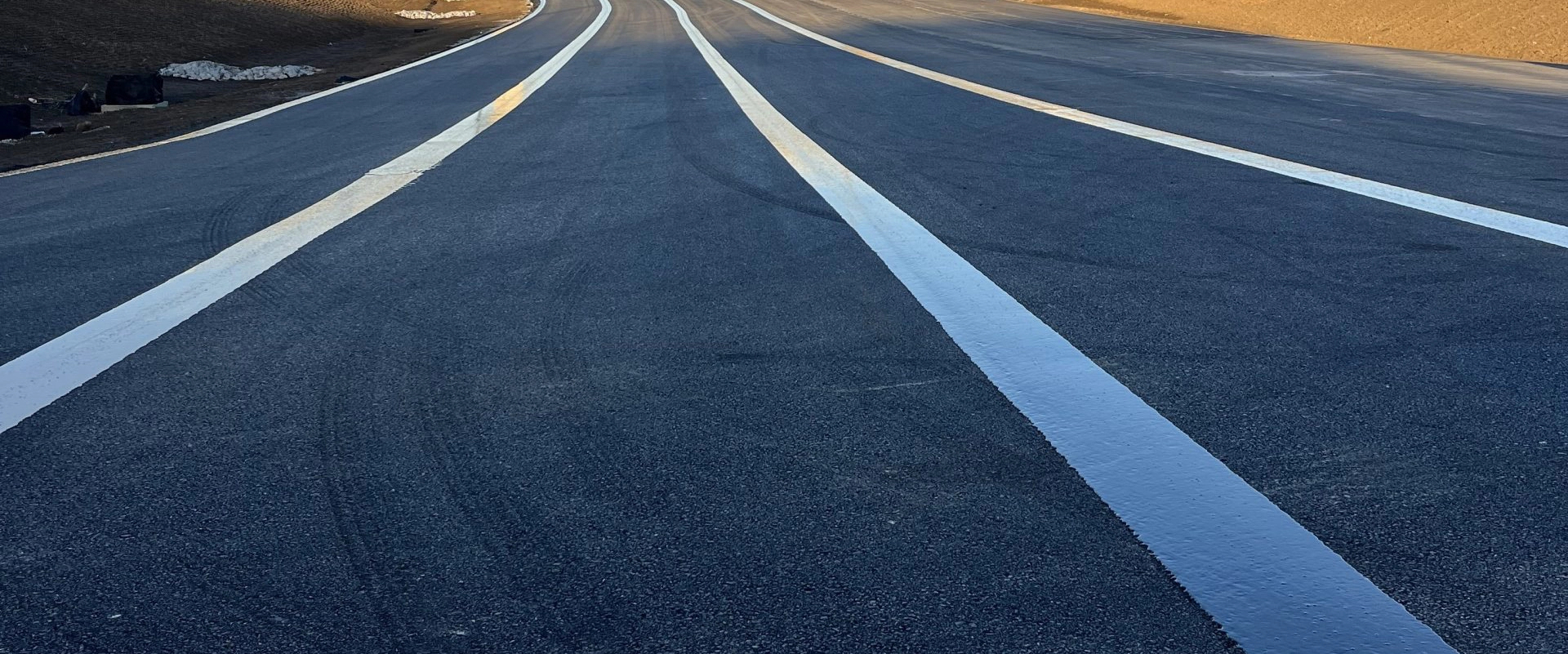

- Why? Because VRAM preserves the most expensive part of your road. The two feet around the centerline longitudinal joint often contains striping, raised pavement markers (RPMs) and rumble strips; this vulnerable part of the pavement is most often the first section to require repair. VRAM protects this important area by filling the air voids present at the joint, making the centerline area more durable and impermeable to stand the test of time.

For Contractors

- The adoption of VRAM marks significant progress for road safety and efficiency. With a VRAM seamlessly added to the asphalt construction process, the issue of density testing at the centerline joint can be waived. VRAM fills air voids with a polymer-modified asphalt, making the voids in this area similar to or less than the rest of the asphalt mat. Centerline maintenance and repairs are also significantly reduced, keeping workers away from the most hazardous part of the road.

- How does the construction process work? A contractor applies the VRAM at the location of the future longitudinal joint, using a state specified application method. The road is then ready for construction traffic in less than 30 minutes.

For Consulting Engineers

- For years, the problem of premature longitudinal joint failure has plagued road builders. Specifying VRAM solves this age-old issue, extending the lifespan of the asphalt overlay an additional 3-5 years beyond the typical goal of 15 years. The efficacy of VRAM has been examined in many published research studies and proven through precedent projects in 28+ states.

- Want to learn more? Visit Jband.com to view the studies here or reach out to the team at jbandinfo@thgrp.com.

Additional Insights on INDOT’s VRAM Adoption

- VRAM has been used in INDOT roads since 2016.

- Currently, 27 states (plus Washington D.C.) have used a VRAM. Click here for a full map of VRAM use by state.

- This decision is backed by evidence. Starting with IDOT’s 20-year VRAM success story on US-51, a diverse collection of case studies display the ability of VRAM to delay pavement cracking when compared to control sections.

Multiple institutions have studied VRAM, leading to the following research conclusions:

- “The life extension of the joint area is approximately three to five years, and the benefit is calculated to be three to five times the initial cost.” - TRB Study

- “[With VRAM], longitudinal cracking at the joints will be delayed relative to the control sections because more energy will be needed for cracking to occur... The use of VRAM also reduces permeability and air void content, which reduces the intrusion of water into the pavement, indicating that good long-term pavement performance will be achieved.” - MnDOT Study

- “The application of the J-Band VRAM product significantly reduced the permeability of the compacted asphalt at the longitudinal joint. On average, the permeability of the J-Band treated longitudinal joint was approximately 24 times slower than the conventional longitudinal joint.” - CAIT/ Rutgers Study

Fun Fact

- In 2004, VRAM was used in the re-paving of the Indianapolis Motor Speedway. Before this upgrade, the track required resurfacing every 8 to 9 years. However, with VRAM protecting the longitudinal joints, the Speedway has held strong for two decades of intense racing. That is 20 years of performance, powered by J-Band VRAM.

INDOT’s adoption of VRAM presents an exciting opportunity for Hoosiers to save time and money in their roadway maintenance. Innovative VRAM technology not only promises cost-effective and long-lasting pavements, but it also offers safer roads for everyone.

Indiana chooses VRAM for category 2-4 roads – Will your projects keep up?