For decades, road managers have tried to find a reliable fix for the consistent weakness in the center of every road. Over time, longitudinal construction joints are the first part of the pavement to crack and fail. Topical solutions have not been able to address the issue completely and require additional maintenance over the life of the road.

As the adage goes, necessity is the mother of invention. In the early 2000s, a team of innovative industry professionals flipped longitudinal joint failure on its head, creating a product to fix the problem prior to construction.

The Solution to Joint Failure

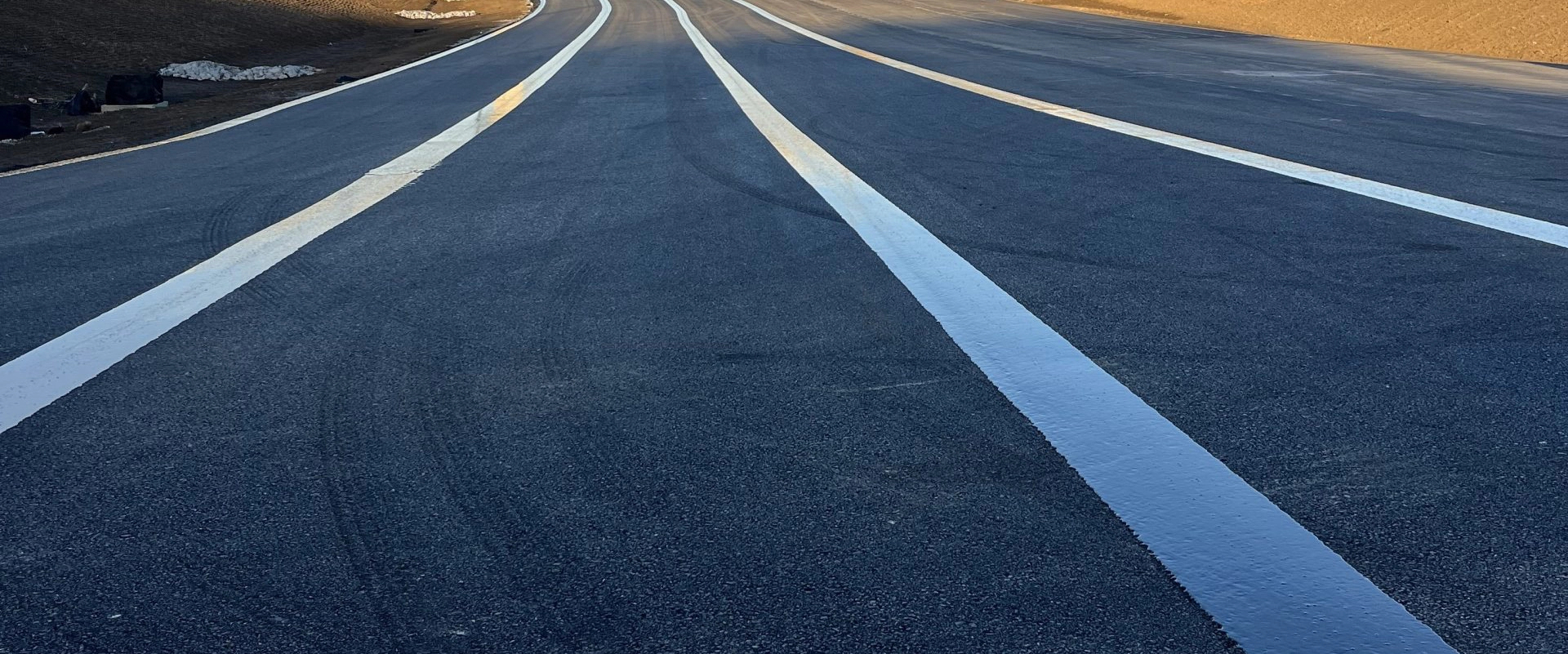

J-Band®, a void reducing asphalt membrane (VRAM), is a highly polymer-modified asphalt cement that is placed on the pavement in the area of the longitudinal joint prior to hot mix asphalt paving. The hot asphalt and pressure from the rolling operation cause the VRAM to migrate up into the mat, significantly reducing the voids that lead to deterioration of the joint.

In 2001, the Illinois Department of Transportation (IDOT) was the first state agency to use J-Band as part of the road construction process. Because of the control sections in those projects, we can see a dramatic difference in joint performance with and without J-Band.

The Results of Innovation

When creating J-Band, the team had three primary goals for the product: save highway users and agencies TIME, MONEY and LIVES.

TIME

People need a solution that is fast and does not slow down construction or traffic. J-Band application seamlessly integrates into paving. In less than 30 minutes after it’s sprayed, the material is traversable. It also saves agencies from time-consuming maintenance in years to come.

MONEY

J-Band's economic value proposition is spelled out in this 2021 TRB Research Study by IDOT. Meticulous calculations reveal that J-Band has a 3-5x return based on its cost at the time of installation.

Furthermore, using data from multiple state’s DOTs, a tool has been created to calculate return on investment when using J-Band®.

LIVES

With J-Band protecting the longitudinal joint, the lifespan of the asphalt overlay is significantly extended, translating to less maintenance at the joint. The centerline paving joint is next to live traffic, the most sensitive position for workers. J-Band dramatically reduces that situation.

Further Use-Case for J-Band

J-Band has also added value to rumble strips. Rumble strips are an essential safety feature but have the disadvantage of often being cut on top of the already vulnerable longitudinal joint. J-Band reinforces the joint, keeping rumble strips intact and functional for the motoring public.

What’s Next for J-Band?

As of 2024, VRAM has been applied in 27 states and well as the District of Columbia. Dave Henderson, Executive VP at Asphalt Materials Inc. shares, “We see tremendous opportunity for growth, and probably what I’m most excited about is the opportunity for international expansion.”

J-Band is undoubtedly a success. It uniquely tackles a big problem by addressing the true need of customers: making roads last longer for less.

Editor's Note

J-Band® is a product of Asphalt Materials, Inc. and created in the labs of Heritage Research Group. J-Band® is a registered trademark of Asphalt Materials, Inc.