Rumble Strips are an Important Safety Measure

With more than 42,900 fatalities occurring on U.S. highways each year, roadway safety remains one of the most challenging issues facing our country. (1)

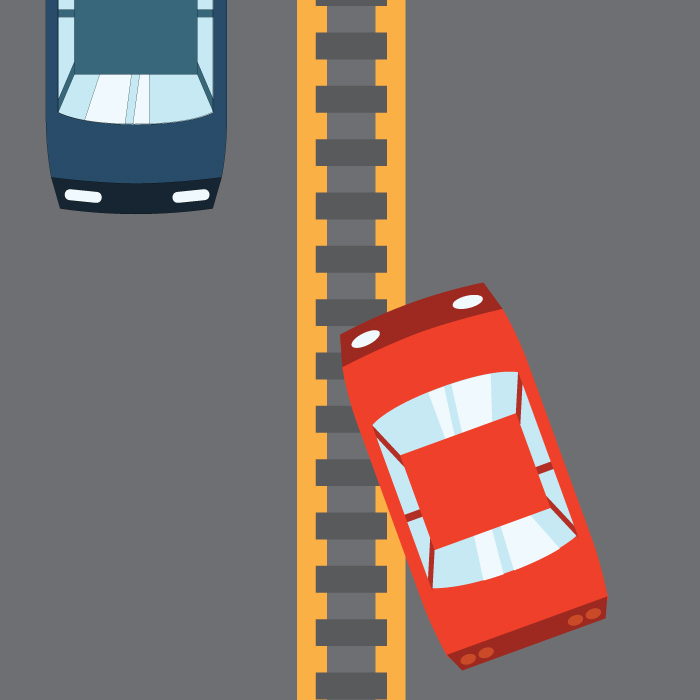

Rumble strips are a safety measure used to address one of the most serious types of traffic crashes: a lane departure crash. Rumble strips consist of a set of transverse grooves applied on the shoulder or centerline of a roadway. In Ohio, House Bill 51 was introduced during Ohio’s 133rd General Assembly to require center-line rumble strips (CLRS) for certain highway projects.

OH HB51 Bill Summary

Although HB 51 did not pass, The Ohio Department of Transportation (ODOT) will install rumble strips along the center line for two-way, undivided state highways with a speed limit exceeding 45 miles per hour, as a part of specified highway projects.

Expect More Rumble Strips in the Future. For Good Reasons!

Rumble strips provide a tactile and audible warning to alert inattentive (distracted, drowsy, unfocused, etc.) drivers who may unintentionally drift out of their lane. This warning gives the driver an opportunity to correct their action or reduce speed, which may help them avoid or reduce the severity of a crash.

ODOT Wood County – Highway US-23 (July 29-30, 2022)

A Void Reducing Asphalt Membrane (VRAM) project took place across a 5.83-mile two-lane highway running from Cygnet Road through the Village of Risingsun, Ohio, and north to US-6. This project involved a 3-1/4” mill with 1-3/4” Binder Course which was then topped with a 1-1/2” 12.5mm Type A (446) Surface Course. VRAM was placed on top of the new Binder course before the Surface Course was laid.

Prime Contractor: Gerken Materials Inc.

Applicator: Gerken Materials Inc.

Value of Rumble Strips

Shoulder rumble strips have been in use all over the country for many years and their safety benefits are well-documented, but centerline rumble strips (CLRS) are relatively new. A three-year study in Michigan showed that a before-and-after crash study performed, found significant reductions across all crash severities and lane departure crash types, including:

- 50 percent reduction in head-on crashes

- 46 percent reduction in run-off-the-road crashes

- 51 percent reduction in fatal crashes

- 41 percent reduction in incapacitating injury crashes

Rumble strips have become a safety standard on MDOT roadways and will continue to save lives in the years to come as Michigan moves Towards Zero Deaths. (2)

How to Keep Joints Protected?

But making roads safer doesn’t have to mean making joints weaker. Contractors in Ohio are adding J-Band®, a void-reducing asphalt membrane (VRAM), a materials solution designed to strengthen the middle of the road. Created in the labs of Heritage Research Group, J-Band is designed to address the issue of protecting centerline joints from a different angle: the bottom up. It’s a materials approach applied at the time of construction, under the surface where centerline rumble strips will be built.

US-23 Project in Wood County, Ohio

Personnel on the project included ODOT Inspector Robbie Miller, Gerken Project Manager Kyle Boserman, paving foreman Tony Haar, distributor operator Randy Coleman and Chad Crosby of Asphalt Materials. Tony has paved over VRAM before, so the checklist was reviewed with the ODOT inspectors who had never seen VRAM applied before.

Work for these two days consisted of VRAM application and paving on the southbound lane against traffic. Work on the 30th consisted of paving the northbound lane to match the previous days joint. Work on this project was done in two-day intervals so as not to leave VRAM exposed for an extended period of time. The VRAM application on the 29th started at 8:10 am.

HMA Paving Observations

Paving on the 29th of July in the southbound lane against traffic with 1-1/2” 12.5mm Type A (446) Surface Course began at 8:40 am. The equipment train consisted of a RoadTec 190e paver, (2) CAT CB54 Steel Drum Rollers, and a Volvo DD118HF Steel Drum Roller. The one CAT roller and the Volvo roller were working as breakdown rollers. Each was making 6 vibratory passes across the mat. The other CAT roller was working as the finish roller in vibratory mode. Paving on the 30th of July in the northbound lane matching the previous day’s joint with 1-1/2” 12.5mm Type A (446) Surface Course began at 8:00 am.

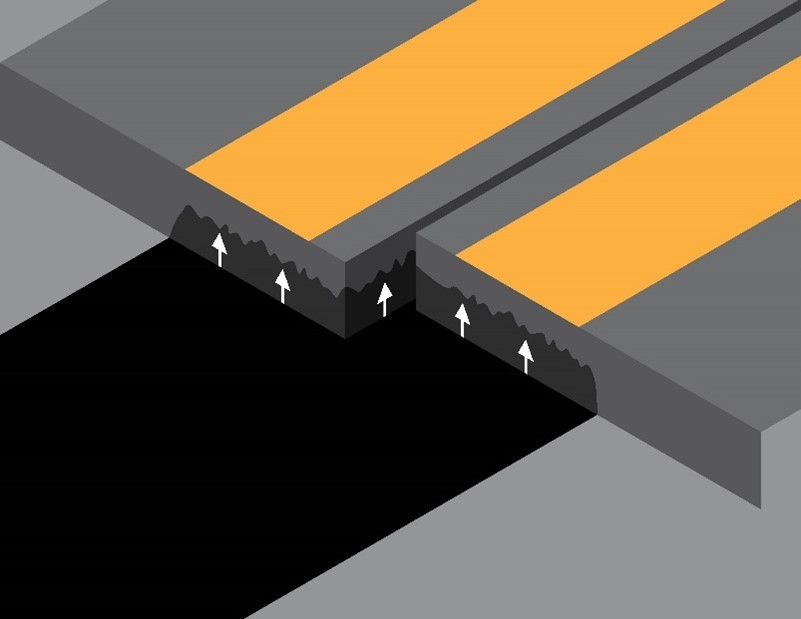

VRAM Migrates Upward Into the HMA Mat

A shadow could be seen on the mat surface above where the VRAM had been placed indicating a successful migration of VRAM upwards into the mat. (HMA = Hot Mix Asphalt)

Rumble Strips Installed

For the ODOT US 23 Wood County project, rumble strips were installed by being cut into the pavement on August 16. (video included below)

If rumble strips are not protected, damage can occur after just a few seasons of water damage. This not only defeats the purpose of the rumble strips but can also add additional hazards in the centerline of the road with potholes and drivers swerving to avoid these hazards. (Note the pictures to the right which show how much damage can be done to unprotected rumble strips in on a few seasons of exposure. This picture is from west central Indiana)

Protecting Rumble Strips with VRAM and RPE

Since centerline joints are particularly susceptible to water damage. For new pavements that will have rumble strips, it is critical to treat them proactively to avoid negative consequences in the future. In addition to VRAM being placed prior to paving, RPE as an application on top of the area where rumble strips are installed can also be a smart strategy.

This past April, the Wisconsin Highway Research Program published a research brief detailing the Material Specifications for Longitudinal Joint Construction, Remediation, and Maintenance. This brief indicated the strategy of using both VRAM prior to HMA being laid and RPE after, as being a strategy others should consider. If you are interested in learning more about the Wisconsin research brief, the final report is available on the WisDOT Research website and the link: https://wisconsindot.gov/Pages/about-wisdot/research/default.aspx

You can also find this study and others involving VRAM, on the Resources tab here on TheJointSolution.com website.

What Makes VRAM Work so Well?

VRAM, as a Void Reducing Asphalt Membrane (VRAM), fills a portion of the voids with asphalt content from the bottom up. It is a materials approach to addressing issues experienced at the longitudinal joint due to air and water infiltration. (see graphic on the right showing upward migration of VRAM)

Applying J-Band®, an industry-leading VRAM, at the time of construction, under the surface where centerline rumble strips will be installed, will reduce permeability in this most critical area, extending the life of the joint and improving the performance of the entire pavement.

Installing rumble strips on the US-23 project in Wood County, Ohio. (View video below.)

Learn More About Asphalt Material’s VRAM

J-Band® is a VRAM product from Asphalt Materials, Inc. that was created in the labs of the Heritage Research Group. VRAM has been helping roads last longer since 2002 and has been used in 23 States and The District of Columbia. You can review previous J-Band projects, studies, a lifecycle calculator, studies, and more by visiting other areas of the TheJointSolution website.

Sources:

1 – U.S. Department of Transportation Federal Highway Administration, FHWA Home / Safety / Roadway Departure / Center Line Rumble Strips (T 5040.40)

2 – Towards Zero Deaths. https://www.michigan.gov/mdot/travel/safety/efforts/tzd#:~:text=The%20Michigan%20Department%20of%20Transportation,driver%20behavior%20and%20improve%20safety.

Editor’s Notes:

HMA is an acronym for Hot Mix Asphalt.

VRAM, Void Reducing Asphalt Membrane, is referred to in Illinois as LJS, Longitudinal Joint Sealant.

J-Band® and CCAP ® are registered trademarks of Asphalt Materials, Inc.

AMIBIND™, AMIBOND™, AMICYCLE™, AMIGUARD™, AMISEAL™ are trademarks of Asphalt Materials, Inc.

Additional Pictures from the US-23 Project in Ohio.