If you have reviewed the draft DOT Strategic Framework, you will note the agency’s priorities for achieving their mission through six strategic goals. We would like to take a deeper look at those elements that are related to Safety, Transformation and Organizational Goals for this particular article. The Department of Transportation (DOT) published their draft Strategic Framework (For Fiscal Years 2022-2026), for public comment in November 2021.

DOT’s Safety Goals Defined

The DOT has stated that they want to see our transportation systems being safer for all people. They want to work toward a future where transportation-related serious injuries and fatalities are eliminated.

- Safe Workers: Support the health and safety of transportation workers and first responders.

- Safe Design: Design and build transportation infrastructure, vehicles, and systems to improve safety outcomes.

Asphalt Materials’ products and services are highly aligned with the DOT’s Safety Goal, specifically around technologies that can help create longer-lasting, safer roads.

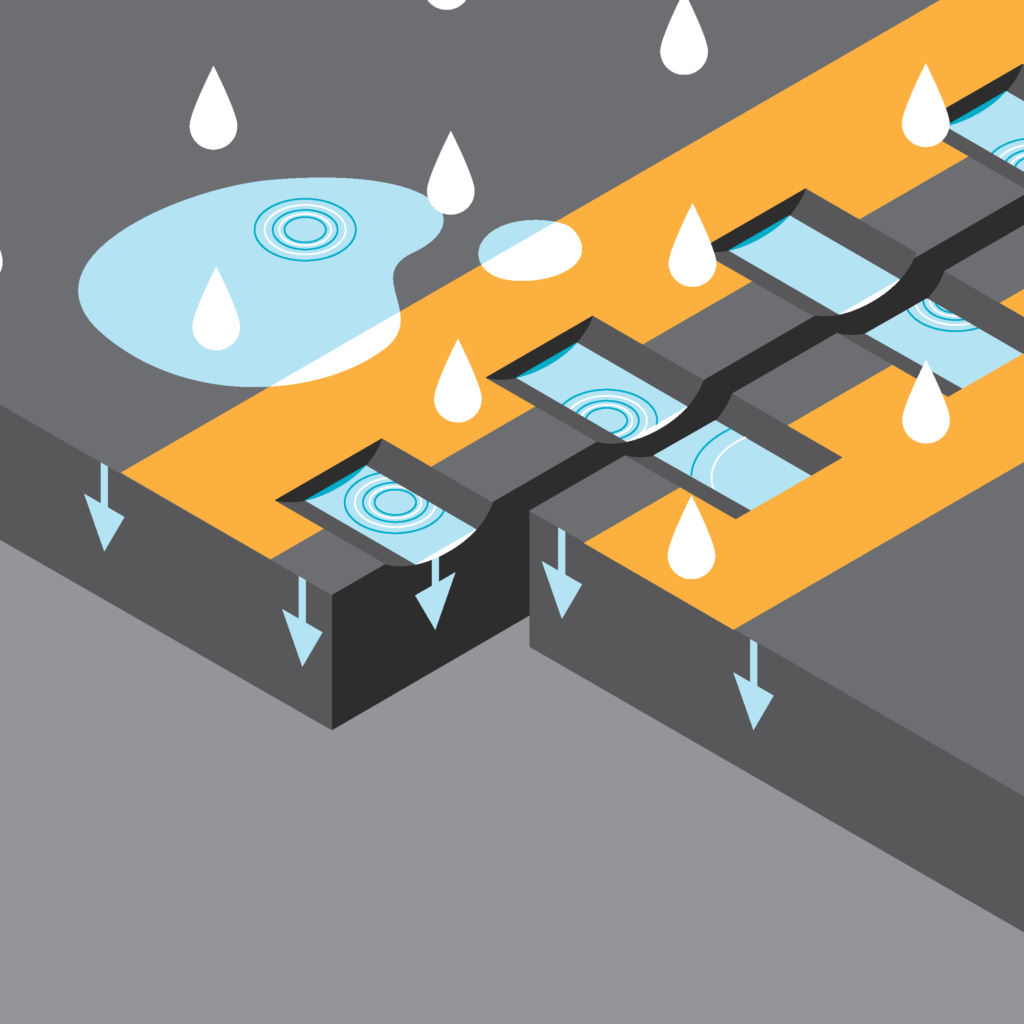

- J-Band is a technology that has been shown to save lives. When roads last longer, workers and the traveling public are safer. J-Band is a VRAM, a void reducing asphalt membrane that fills voids with asphalt content and therefore reduces permeability.

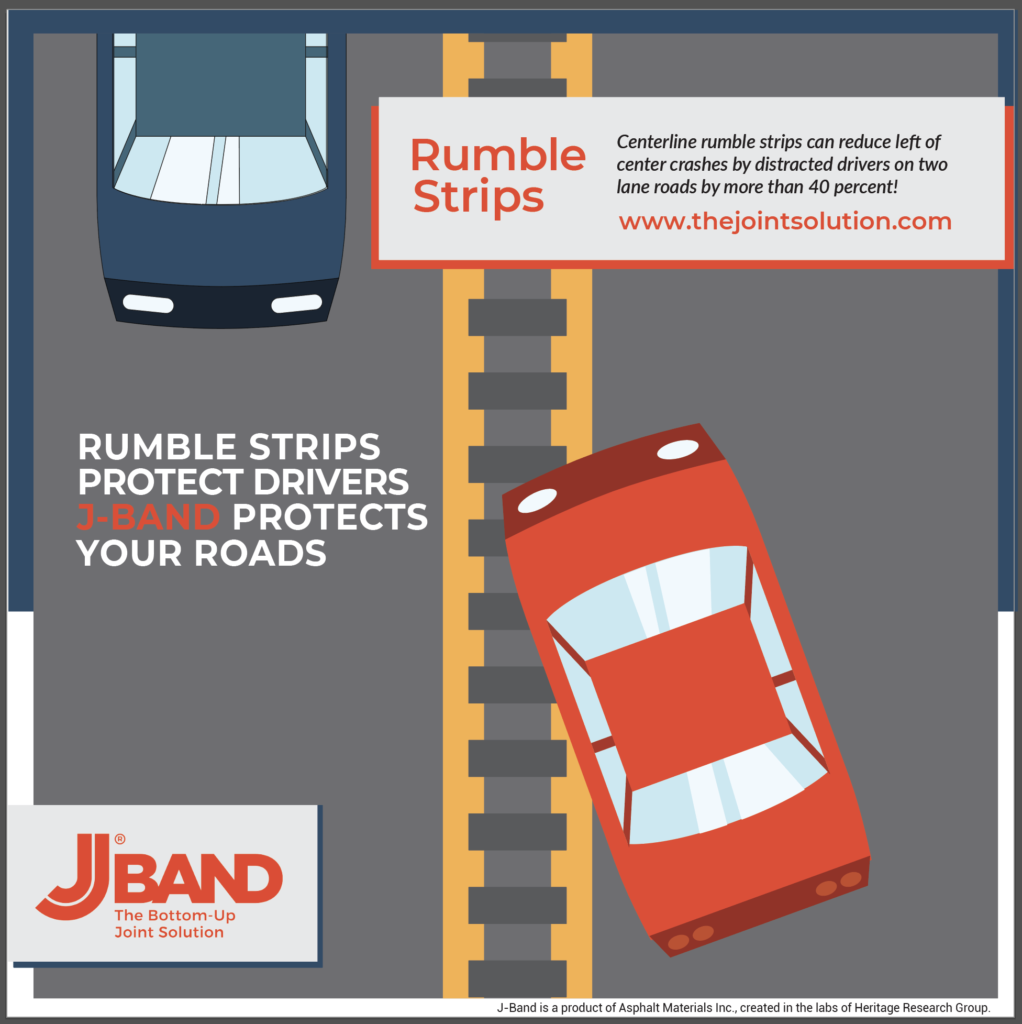

- J-Band is a particularly effective innovation to help the longitudinal joints of roads last longer and therefore need fewer repairs. Rumble strips are a proven method used to reduce left of center crashes. When VRAM is used on roads with rumble strips, roads can last longer, because it helps reduce permeability in the area of the pavement below where the rumble strips are installed.

DOT’s Transformation Goal Defined

Design for the future. Invest in purpose-driven research and innovation to meet the challenge of the present and modernize a transportation system of the future that serves everyone today and in the decades to come.

Objectives:

- Matching research and policy to advance breakthroughs: Foster breakthrough discoveries and new knowledge through high-risk, high-reward research driven by policy objectives

- Experimentation: Identify new ideas, new innovation, and new possibilities. Evaluate the opportunities and risks so the Department can support public benefits

- Collaboration and Competitiveness: Work with diverse stakeholders to share noteworthy practices and accelerate the adoption of innovation and technologies

- Flexibility and Adaptability: Design flexibility into transportation system investments to accommodate and respond to changing needs and capabilities to provide long-term benefits

Asphalt Materials’ products and services are highly aligned with the DOT’s Transformation Goal, specifically related to breakthrough discoveries, new ideas and innovations.

- J-Band is a materials approach that is different than other traditional methods used to extend the life of pavements. Many of the traditional methods are mechanical in nature.

- J-Band is a breakthrough discovery, a new idea and innovation. It was discovered in the labs of The Heritage Research Group. It is a materials approach that can fill the majority of air voids in the longitudinal joints of pavements.

- J-Band has been used over 20 states and The District of Columbia. These states can collaborate with other states to accelerate the adoption of the VRAM technology to bring this innovation to their road networks.

DOT’s Organizational Goal Defined

To advance the Department’s mission by establishing policies, processes, and an inclusive and innovative culture to effectively serve communities and responsibly steward the public’s resources.

- Data-Driven Programs and Policies: Develop and manage data systems and tools to provide objective, reliable, timely, and accessible data to support decision-making, transparency, and accountability

- Evidence-Based Budgeting: Continuously improve budget formulation to be more inclusive and transparent, so that it identifies enterprise-wide needs, fully justifies resource requests, and educates the public on the value of their transportation investments.

- Oversight, Performance, and Technical Assistance: Improve program delivery and management of requirements, funding, contract performances, and program outcomes through effective planning, administration, and oversight of grants and contracts; increased technical assistance to stakeholders; and enhanced analytics.

Asphalt Materials’ products and services are aligned and can help with certain elements of the DOT’s Organizational Goal, specifically around data, analytics, and the value of infrastructure investments.

- The benefits of J-Band are long-lasting. It has been studied and evaluated in test vs. control situations in states such as Illinois since 2002. We are excited about the opportunity to bring this technology to the other 29 states that have not yet experienced J-Band.

- The Transportation Research Board, in partnership with the State of Illinois DOT and the Indiana DOT have been instrumental in helping develop a life-cycle cost calculator. Analytics have shown that J-Band is a breakthrough discovery that helps roads last up to 5 years longer and delivers a return on investment of 3 to 5 times its cost

- J-Band provides long-term benefits as shown in an Indiana DOT life cycle analysis where an investment of $12.5M in J-Band can result in more sustainable a $39M in savings (approximately 3:1 ROI).

We are excited to see how the DOT’s goals for safer roads will translate to lives of drivers and construction workers being saved. We expect to see more local and state DOTs installing centerline and edgeline rumble strips to protect drivers. We also expect to see more states using innovative, proven technologies like VRAM at time of construction.

J-Band is an Innovative Technology Discovered in Indiana and Developed in America to Solve to the Longitudinal Joint Problem.

Developed at the laboratories of Heritage Research Group, J-Band is applied during the road construction process just below the joint. Once covered, it migrates upwards filling the voids that can be penetrated by water and air, preventing damage before it can start.

Less maintenance is also an investment in safety.

• Over 700 people die in work zone crashes annually.1 Longer-lasting roads decrease the amount of time workers are exposed to middle of the road danger.

• Because of distracted driving, centerline rumble strips are becoming increasingly common. They can reduce head-on collisions by up to 50%2 and can be installed without compromising road life when J-Band is applied.

• A safe job is a good job — something America always needs more of.

The pictures shown in this article demonstrate how well a project from a previous year is holding up because of the use of J-Band at the time of construction.

1 National Workzone Safety Information Clearinghouse

2 U.S. Department of Transportation Federal Highway Administration, FHWA Home / Safety / Roadway Departure / Center Line Rumble Strips (T 5040.40)

The pictures below show what roads NOT treated with J-Band look like 2, 4 and even five years after initial construction.

The pictures below show what roads that were treated with J-Band look like 2, 4 and even five years after initial construction.