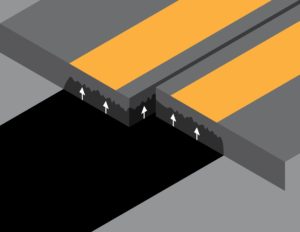

The longitudinal joint is the Achilles’ heel of every road. Road managers know the first part of the pavement to fail is the longitudinal joint. As the road’s most permeable part, this joint is susceptible to the elements. Air and water work down through this unavoidable seam in the pavement causing the joint to deteriorate, crack and pothole. And when the longitudinal joint fails, the rest of the road soon follows — triggering the need for even more maintenance. (1) The goal of this Steuben Co. project is to fill a portion of the centerline voids with an asphalt product from the bottom up. This is a materials approach to protecting joints and is referred to as a Void Reducing Asphalt Membrane, or VRAM.

This 151,233-foot project in Steuben County, Indiana runs from 1.12 miles north of US 20 to 2.06 miles north of SR 120 near the Michigan state line. Illiana employees Cullen and Ben were present to assist with the project. VRAM application began at 8am with the 6715-distributor shooting from the passenger side. They started in the southbound passing lane. Ambient temperature was 51F; pavement temperature was 59F. The VRAM application target was 18” wide and 1.51 lb./ft for the 2” surface. This was over a recently applied level binder mix. (2)

J-Band® is a VRAM and is helping set the standard as a proven approach that protect joints from premature failure. (3)

Paving started at the at 8:35am. On September 10, 2021

Morning temperature was 57F with pavement temp at 65F. The mix was an IN 9.5mm SMA mix at 2” mat thickness. This project’s paving equipment consisted of a Weiler E2850 MTV, Vogele Super 1800-3i spray paver, Dynapac CC7200-15-ton breakdown roller, Volvo DD140C-12-ton intermediate roller and a Hamm HD-120i-12-ton finish roller. Paving width was 12 feet with mix temp at 285F under the screed. Spray rate was 0.15 gal/yd². Breakdown roller was making 5 vibratory passes along with 3 vibratory passes with the intermediate roller.

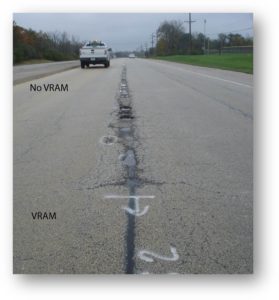

VRAM has a 20+ Year Track Record

The picture below shows a 15 year old pavement with one section that utilized VRAM at the time of construction and a ‘control’ section that did not. Since 2002, J-Band has been used to save infrastructure funds in 21 states and the District of Columbia.

What’s Next for VRAM? J-Band?

Multiple DOTs have discovered that J-Band doesn’t cost. It pays! Since 2002, J-Band has been used to save infrastructure funds in 21 states and the District of Columbia. An investment in protecting the longitudinal joint helps roads last up to 5 years longer and typically delivers a return on investment of 3 to 5 times its cost. Every dollar invested in J-Band can save at least two dollars in avoided and deferred maintenance costs.

Notes:

(1) The density and air void content of asphalt mixtures affect the durability and performance of asphalt pavements. Pavement longitudinal joints typically have a lower density than the mat because they receive less compaction than the center section of the mat for various reasons. The higher air void percentages resulting from lower densities can lead to high permeability and allow water infiltration, which in turn can cause moisture-induced damage and decrease base and subbase support to the pavement, reducing pavement life. Void-reducing asphalt membrane (VRAM) has been used at the longitudinal joints of asphalt pavements to achieve higher densities and prevent moisture infiltration, thereby reducing deterioration at the longitudinal joints. VRAM is applied before the hot-mix asphalt (HMA) layer is placed and migrates into the HMA to fill 50% to 70% of the air voids. (Iowa State University Study for Minnesota Department of Transportation, DEC. 2020)

(2) Depending on the situation VRAM can be sprayed at different width’s. This article notes 18” which is a typical application width for centerline applications.

(3) VRAM (Void Reducing Asphalt Membrane) is referred to in Illinois as LJS, Longitudinal Joint Sealant.

J-Band® is a product of Asphalt Materials, Inc. and was created in the labs of The Heritage Research Group.