Reducing fatalities on rural roads remains a major challenge in the United States. In 2016, 18,590 lives were lost on rural roads-more than half of all traffic deaths-even though only 19 percent of the U.S. population lives in rural areas. Two-thirds of these rural fatalities involved a roadway departure, where a vehicle crosses a center line, an edge line, or otherwise leaves its travel lane. Substantial safety improvements on rural roads can be difficult to make due to the size of the rural road network, which accounts for approximately 70 percent of public road mileage. (1)

Two of the most important roadway departure countermeasures that can be applied include:

- Signage and markings that can help drivers navigate lane edges

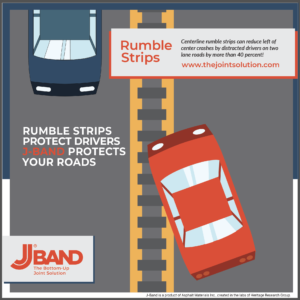

- Rumble strips that can alert drowsy or distracted drivers from drifting out of their lane of travel

Every agency can identify areas on their network at highest risk for roadway departures and systemically apply safety treatments that are in sync with their State’s Strategic Highway Safety Plan (SHSP). (1)

MINNESOTA CASE STUDY: Minnesota’s Systemic Approach Integrates Safety Performance into Investment Decisions for Local Roads

To develop the safety plans, MnDOT conducted a statewide, comprehensive crash analysis as documented in the Federal Highway Administration (FHWA) Systemic Safety Project Selection Tool. MnDOT’s approach involved developing Road Safety Plans (RSPs) for each of the state’s 87 counties, building on Minnesota’s Strategic Highway Safety Plan (SHSP), to identify specific safety projects that would directly address the factors associated with the most severe crashes on each county’s highway system. (2)

Historically, approximately 60 percent of severe (fatal and serious injury) crashes have occurred on Minnesota’s local road system. As the crashes occurred throughout many miles of roadways, the low crash density had resulted in the roads receiving minimal safety investment based on the traditional site analysis approach. (2)

To address this issue, the Minnesota Department of Transportation (MnDOT) assisted the counties in identifying low-cost, safety-related projects to implement on a systematic basis. The result has been far fewer fatalities on the county roadways. (3) MnDOT compiled an initial list of the safety countermeasures that had the greatest potential to address the focus crash types. (4)

The priority safety strategies eventually selected for the three focus areas included enhanced road edges with rumble strips and 6-inch edge lines, enhanced curve delineation {chevrons), and upgraded traffic signs and streetlights for intersections. MnDOT added this systemic component to its Highway Safety Improvement Program {HSIP) in order to fund the projects that the RSP program helped the counties identify. (2)

Investments in Longer-lasting Roads is Also an Investment in Safety

Less maintenance is also an investment in safety for workers and the driving public. Over 700 people die in work zone crashes annually. (5) Longer-lasting roads decrease the amount of time workers are exposed to middle of the road danger. Because of distracted driving, centerline rumble strips are becoming increasingly common. They can reduce head-on collisions by up to 50% (6) and can be installed without compromising road life when VRAM is applied.

Rumble Strips Can Create Issues for Road Longevity

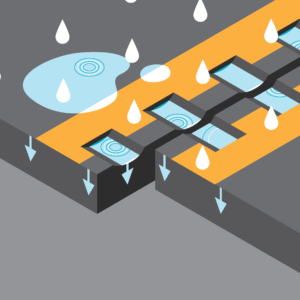

Longitudinal joints are the Achilles’ heel of every paved road. Road managers know the first part of the pavement to fail is the longitudinal joint. As the road’s most permeable part, this joint is susceptible to the elements. Air and water work down through this unavoidable seam in the pavement causing the joint to deteriorate, crack and pothole. And when the longitudinal joint fails, the rest of the road soon follows — triggering the need for even more maintenance. (7 – Iowa State Study for Minnesota DOT)

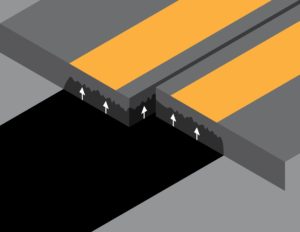

The goal of VRAM is to fill a majority of the centerline voids with an asphalt product from the bottom up. VRAM stands for Void Reducing Asphalt Membrane. (8)

Since 2002, J-Band® (a VRAM) is helping set the standard as a proven approach that protect joints from premature failure.

VRAM has a 20+ Year Track Record

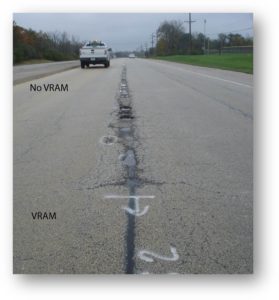

The picture below shows a 15 year old pavement with one section that utilized VRAM at the time of construction and a ‘control’ section that did not.

What’s Next for VRAM? J-Band?

Multiple DOTs have discovered that J-Band is an investment in building longer-lasting, safer roads. Since 2002, J-Band has been used to save infrastructure funds in 21 states and the District of Columbia. An investment in protecting the longitudinal joint helps roads last up to 5 years longer and typically delivers a return on investment of 3 to 5 times its cost. Every dollar invested in J-Band can save at least two dollars in avoided and deferred maintenance costs.

———

Notes:

- Everday Counts- https://www.fhwa.dot.gov/innovation/everydaycounts/

- https://www.fhwa.dot.gov/innovation/everydaycounts/edc_5/roadway_departures.cfm

- Roadway Departure Safety: https://safety.fhwa.dot.gov/roadway_dept/

- FHWA Crash Emphasis Areas: https://safety.fhwa.dot.gov/roadway_dept/strat_approach/brochure/

- National Workzone Safety Information Clearinghouse

- S. Department of Transportation Federal Highway Administration, FHWA Home / Safety / Roadway Departure / Center Line Rumble Strips (T 5040.40)

- The density and air void content of asphalt mixtures affect the durability and performance of asphalt pavements. Pavement longitudinal joints typically have a lower density than the mat because they receive less compaction than the center section of the mat for various reasons. The higher air void percentages resulting from lower densities can lead to high permeability and allow water infiltration, which in turn can cause moisture-induced damage and decrease base and subbase support to the pavement, reducing pavement life. Void-reducing asphalt membrane (VRAM) has been used at the longitudinal joints of asphalt pavements to achieve higher densities and prevent moisture infiltration, thereby reducing deterioration at the longitudinal joints. VRAM is applied before the hot-mix asphalt (HMA) layer is placed and migrates into the HMA to fill 50% to 70% of the air voids. (Iowa State University Study for Minnesota Department of Transportation, DEC. 2020)

- VRAM, Void Reducing Asphalt Membrane is referred to in Illinois as LJS, Longitudinal Joint Sealant.

J-Band® is a product of Asphalt Materials, Inc. and was created in the labs of The Heritage Research Group.