Recently, Asphalt Materials, Inc. (AMI) collaborated with ClimeCo to complete an LCA-based sustainability assessment of J-Band®, AMI’s void reducing asphalt membrane product.

ClimeCo is a global sustainability company that advances the low-carbon future with market-based solutions. They started with a goal to reduce greenhouse gases (GHG) through scalable abatement projects that create value for their customers. Since their founding, ClimeCo has evolved into a global, full-service advisor, transaction facilitator, trader, and developer of environmental commodities and sustainability solutions for their clients.

A Life Cycle Assessment of J-Band

ClimeCo recently published an article on their website titled, What is a Life Cycle Assessment? Within their article, you will find a link to their final report from this project. We are sharing this information so you can review the project design, data sources, assumptions, approach and findings.

Quantifying The Comparative Effectiveness Of J-Band® To Maintain The Longitudinal Joint

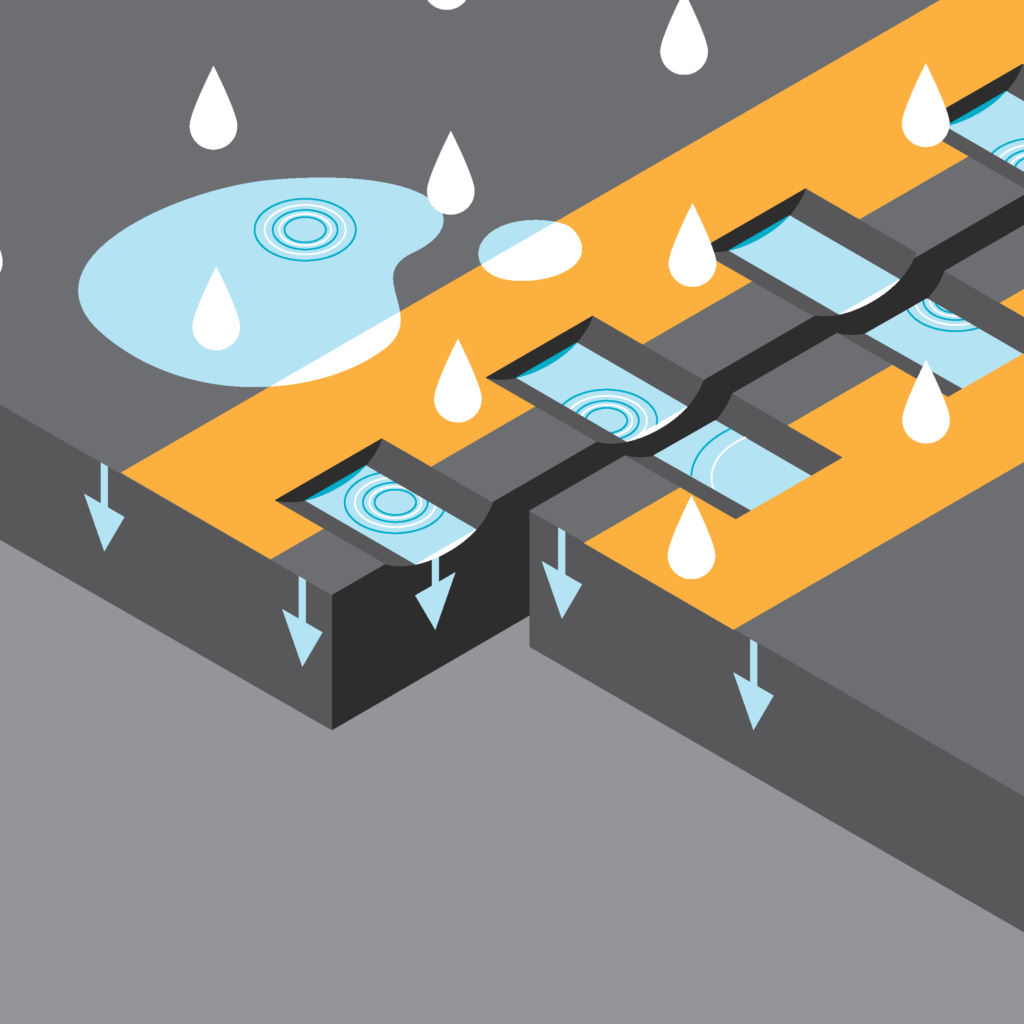

ClimeCo’s comparative life cycle assessment is focused on the singular life cycle of a centerline, or longitudinal joint. The model parameters presented in their report are for a 1-mile stretch of paving that is located 50 miles away from the manufacturing site for J-Band and Joint Adhesive, and 30 miles away for IR Heater and Pave Wide/Trim Back.

GHG (Greenhouse Gas) emissions were analyzed for 4 stages across the life cycle of a road: Manufacturing, transport, application, and maintenance. GHG emissions vary based on different paving distances and transportation distances. A sensitivity analysis was performed to evaluate J-Band’s performance over different model parameters.

The emissions of compounds affecting local human health and environment were compared. Project emissions of regulated criteria air pollutants were comparatively assessed and included volatile organic compounds (VOCs), carbon monoxide, nitrogen oxides (NOx), and fine particulate matter (2.5µ diameter and smaller).

Safety. Application and maintenance work on J-Band is expected to result in far fewer injuries and fatalities compared to the alternatives. The reduction in required maintenance is the largest contributor to the reduced safety incidents of J-Band. Safety metrics were calculated based on expected man-hours for each phase of work, combined with BLS and FHWA safety data.

Importance of Sharing this Information

We believe this information provides meaningful safety and sustainability benefits to current and future infrastructure projects. Agencies, contractors and applicators should have access to this information as they are planning, developing, and implementing their infrastructure and transportation investments.

The ClimeCo team believes their assessment and report can help for the following reasons:

- DOTs have a role to play in helping states achieve state-wide emission reduction targets.

- Energy and GHG emission goals focus on facility usage and electrification of transportation sector.

- There is a rise in programs aimed at increasing the use of ‘green’ products, sustainable practices, and innovative new techniques and materials.

- Life Cycle Analyses (LCA) and Environmental Product Declarations (EPDs) are increasingly common.

- Companies are looking to use new technologies and materials with improved sustainability attributes.

- Many agencies have goals to achieve zero work-zone fatalities.

- Safety is a goal or company value for most applicators and contractors.

The AMI Team will continue to pursue other third-party analysis of our J-Band product. We are excited to learn more about what these future analysis will show and how they can support and build upon the information that the ClimeCo report has generated. This has been a very good first step in our process. Much of the cause of this excitement is due to the following items from the ClimeCo Report.

From ClimeCo’s Assessment:

- ‘J-Band’s benefits go beyond the financial. Its safety benefits and reduced greenhouse gas and pollutant emissions have much to offer customers looking to build a more sustainable future.’

- ‘We believe these results should be recognized, and the role that J-Band can play in the decarbonization of the transportation sector should be emphasized.’

Conclusions

- ‘J-Band’s benefits largely come from the reduced need for maintenance. With minimal repairs needed over the years, maintenance crews can make fewer and shorter trips, preventing greenhouse gas emissions and reducing the number of safety incidences for both workers and drivers.’

- ‘J-Band extends the lifetime of a pavement beyond the 15 years typical of traditional pavement. Over the long term, there are fewer pavement rehabilitations and replacements required with the use of J-Band.’

- ‘In addition to the air quality and greenhouse gas benefits seen in this analysis, the reduced maintenance comes with a significant reduction in emissions from the manufacture of the asphalt compared to alternative joint solutions.’

We encourage you to read ClimeCo’s article and their final report by following the links below. If you would like to learn more about the J-Band assessment by talking with one of our team members, you can email us at Marketing@Asphalt-Materials.com.

Link to the ClimeCo Article: What is a Life Cycle Assessment?

By: Gary Yoder and Jaskaran Sidhu

Link to the ClimeCo Report on J-Band’s Sustainability Assessment

J-Band® is a product of Asphalt Materials, Inc. and was created in the labs of Heritage Research Group.